- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

70kg

-

Size:

-

20*220*45, 200*450

-

Weight (KG):

-

70 kg

-

Product name:

-

Remove Hardness Vertical Fiber Poly Glass Water Tank

-

Application:

-

Carbon Filters/ Multi Media Filter/Softener

-

Certification:

-

ISO9001,CE

-

Usage:

-

Industrial soft water

-

Type:

-

Water Filter Parts

-

Brand name:

-

FEIYUE

-

Certificate:

-

ISO

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Feiyue

-

Material:

-

Wooden frame, FRP

-

Weight:

-

70kg

-

Size:

-

20*220*45, 200*450

-

Weight (KG):

-

70 kg

-

Product name:

-

Remove Hardness Vertical Fiber Poly Glass Water Tank

-

Application:

-

Carbon Filters/ Multi Media Filter/Softener

-

Certification:

-

ISO9001,CE

-

Usage:

-

Industrial soft water

-

Type:

-

Water Filter Parts

-

Brand name:

-

FEIYUE

-

Certificate:

-

ISO

Product Details

Remove Hardness Vertical Fiber Poly Glass Water Tank/Water Softening Plant

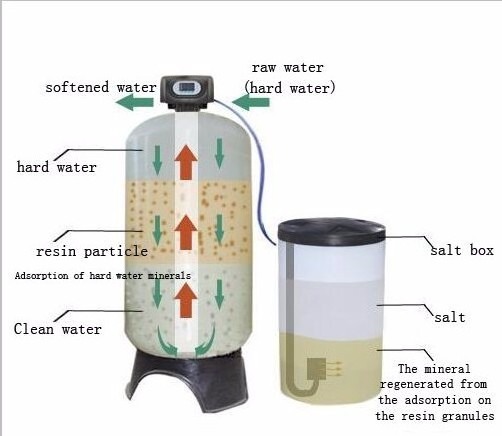

The working process of the water softener is generally composed of the following steps: reverse washing, salt absorption (regeneration), slow flushing (replacement), and quick washing of five processes.All processes of different softening water devices are very close, but there may be some additional processes due to the different or controlled needs of the actual process.

Any softening water device based on sodium ion exchange is developed on the basis of these five processes.Automatic softener running program:

A. operation (work)

Raw water in a certain pressure (0.2-0.6Mpa), flow rate, the body cavity by the controller, into the containers of ion exchange resin (resin cans), resin contained in Na + and the cation in the water (Ca2 +, magnesium 2 +, Fe2 +, etc) to exchange, which makes water of Ca2 +, magnesium 2 + ion content meet the established requirements, to achieve the softening of hard water.

B. Backwashing

After the resins are expired, the backwash is carried out from bottom to bottom before recycling.The purpose of reverse washing is to have two, one is through reverse washing, make the resin layer that runs medium pressure is loosened, favorable to the resin particle and the regeneration liquid to make full contact;The first is that the suspended solids and broken resins accumulated on the surface of the resin are discharged with anti-wash water, so that the flow resistance of the exchanger will not become larger and larger.

C. regenerated salt

The regenerated salt solution is used to restore the original exchange capacity under certain concentration and discharge.

D. replacement (slow cleaning)

In regeneration after the liquid into the, the switch has not involved in the regeneration of exchange in salt solution, use less than or equal to the renewable liquid flow rate of water washed clean (slow), in order to make full use of the regeneration of the salt solution and reduce is wash load.

E. Washing (quick cleaning)

The aim is to remove residual waste from the resin layer and usually clean it at normal flow rate until the water is qualified.

F. Regenerator box water injection

Regenerating the amount of salt needed to regenerate the reagent box

B. Backwashing

After the resins are expired, the backwash is carried out from bottom to bottom before recycling.The purpose of reverse washing is to have two, one is through reverse washing, make the resin layer that runs medium pressure is loosened, favorable to the resin particle and the regeneration liquid to make full contact;The first is that the suspended solids and broken resins accumulated on the surface of the resin are discharged with anti-wash water, so that the flow resistance of the exchanger will not become larger and larger.

C. regenerated salt

The regenerated salt solution is used to restore the original exchange capacity under certain concentration and discharge.

D. replacement (slow cleaning)

In regeneration after the liquid into the, the switch has not involved in the regeneration of exchange in salt solution, use less than or equal to the renewable liquid flow rate of water washed clean (slow), in order to make full use of the regeneration of the salt solution and reduce is wash load.

E. Washing (quick cleaning)

The aim is to remove residual waste from the resin layer and usually clean it at normal flow rate until the water is qualified.

F. Regenerator box water injection

Regenerating the amount of salt needed to regenerate the reagent box

Product Introduction

Product Flow

Product Show

Product Accessories

Product Packing

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: What about your after-sales service?

A: We have one year warranty and if the equipment have troblue,our maintenance engineer will be there in 48 hours.

Q: What is your terms of payment ?

A: We have one year warranty and if the equipment have troblue,our maintenance engineer will be there in 48 hours.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, hope you can cantact me.

If you have another question, hope you can cantact me.

Hot Searches