- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Goodklife

-

Material:

-

Tungsten carbide and High speed steel

-

Hardness:

-

95 - 100 HRC

-

Surface Finish:

-

Ra 0.4 or less

-

Flatness:

-

0.01 or less

-

Size:

-

Customized Size

-

Merits:

-

High hardness and High wear resistance

-

OEM & ODM:

-

Provided

-

After Warranty Service:

-

Video technical support

-

After Sales Service:

-

Online support

-

Certification:

-

ISO 9001

Quick Details

-

Marketing Type:

-

Hot Product 2022

-

Core Components:

-

Other

-

Type:

-

paper blades

-

Brand Name:

-

Goodklife

-

Material:

-

Tungsten carbide and High speed steel

-

Hardness:

-

95 - 100 HRC

-

Surface Finish:

-

Ra 0.4 or less

-

Flatness:

-

0.01 or less

-

Size:

-

Customized Size

-

Merits:

-

High hardness and High wear resistance

-

OEM & ODM:

-

Provided

-

After Warranty Service:

-

Video technical support

-

After Sales Service:

-

Online support

-

Certification:

-

ISO 9001

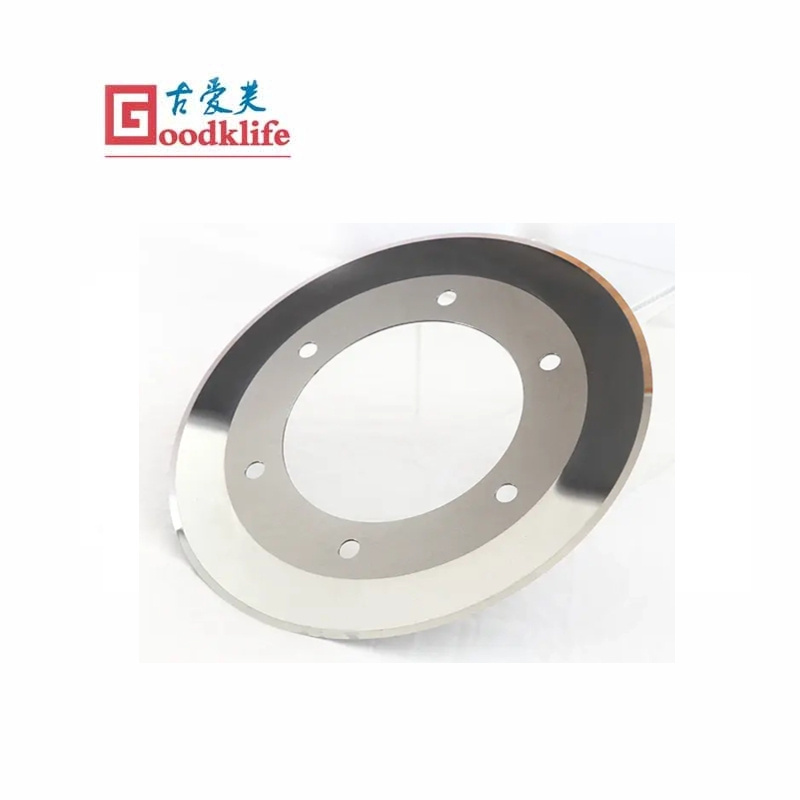

PRODUCTS DESCRIPTION

Logo

Customized Logo

Key Way

Easier Installation

Operator Protection

Marks

Material Code

Production Tracking Code

|

PRODUCT PARAMETER

|

|

|

|

Brand

|

Goodklife

|

|

|

Products name

|

Box cutter round blades for corrugated line machine for paper slitting

|

|

|

Material

|

Tungsten carbide, High speed steel, and customized

|

|

|

Size

|

Customized

|

|

|

Groove

|

as request

|

|

|

Keyway

|

as request

|

|

|

Heat treatment

|

thorough-hardening

|

|

|

Surface Quality

|

precision ground

|

|

|

Surface Finish

|

ra0.4 or less

|

|

TOLERANCE SELECTION

Qualified size tolerance are necessary conditions to ensure that the cutting clearance between the upper and lower shearing blades of the machine is always consistent during dynamic operation. Accurate clearance plays a very important role in shear quality and extended blade life.

Paper package cutting processing and packaging require a variety of cutting applications. Having the right cutter is essential to keep production running smoothly and efficiently. If you are looking for a reliable source of corrugated blades and filter cutters.

Goodklife manufactures the very best cutting and packaging knives available. Nobody knows better than Goodklife the

optimum materials and finishes required for producing the highest quality packaging products. From solid carbides to powdered metal, high speed steel, tool steel and stainless steel, we can help you produce more and faster.

optimum materials and finishes required for producing the highest quality packaging products. From solid carbides to powdered metal, high speed steel, tool steel and stainless steel, we can help you produce more and faster.

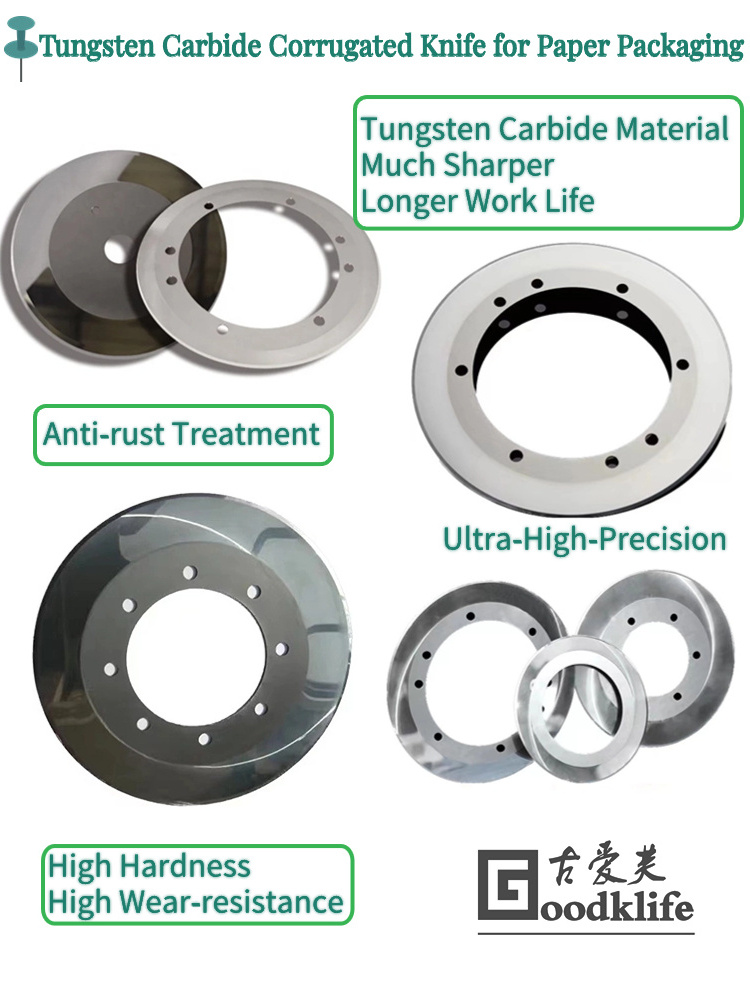

Our manufactures and supplies literally thousands of both standard and custom slitter knives and rotary slitting blades for most applications. Whether you need a straight blade or dished circular blade or a blade with toothed, serrated, scalloped, perforation and saw tooth forms, or even more complex tooth forms. Goodklife can turn your design into a blade in just days. It does not matter if it use for paper cutting, food slicing, packaging, rubber converting, meat chopping, film cutting or foil converting, regardless of its use, our circular knives and blades are exceptionally made from quality ground hardened tungsten carbide and high speed steel as well as carbide.

MATERIAL SELECTION

The first challenge

for cutting blades is avoiding knife crack which means the knife should be good enough for its toughness and ductility. Good toughness and ductility are not enough. The knife should also be good for wear resistance. Thus the knife has long work life. In addition, the blade must also have good high temperature resistance. The knife edge cannot be annealed due to high temperature, otherwise the life will be drastically reduced.

Therefore, the need for appropriate materials to adapt to a variety of cutting conditions.

Our company uses

tungsten carbide, high speed steel, and customized

material as the tool material, and has carried on the rust prevention treatment. the following are the benefits of tungsten carbide:

Our company can choose suitable materials to make cutting tools according to your needs, whether it is material selection, size selection, shape selection or working conditions selection, we can tailor-made for you, according to your machine performance, choose the best material for you to make the products you need, and in the effective delivery period, we will shorten the delivery time for you as far as possible, to ensure the normal operation of your machine, try to give you a full service.

OUTSTANDING PERFORMANCES

Depending on your budget and requirements, our team of experts will develop a customized solution for you,

including but not limited to the selection of cutting blades materials, accuracy, etc. If necessary, our field team will come to your company to study the current cutting problems and improve your cutting quality.

INCREASED LIFESPAN & COST SAVINGS

By selecting the right raw material for the knife and combining it with proven heat treatment processes, we can produce knives that will last significantly longer and thus reduce your tool purchase costs.

SHEARING QUALITY CONTROL

Goodklife cutting blades help you achieve perfect cutting quality control.

Ensure that the gap between each pair of shearing blades is correct and stable.

QUALITY ASSURANCE

SGS AUTHORITATIVE TESTING

Goodklife has always been committed to providing high-quality, ultra-high-precision cutting tools to customers around the world. In order to enhance mutual trust, for the first cooperation, we now provide

free SGS testing

services to invited customers to dispel all your doubts.

HEAT TREATMENT ASSURANCE

Goodklife's heat treatment workshop is fully equipped with various heating, annealing, quenching and tempering equipment, and is equipped with a number of experienced professional senior engineers. After years of experience summarization, the company's unique heat treatment process has been formed.

Blades with a thickness of less than 100 mm can be fully hardened into the core, which can ensure that the performance of the blade is the same until it is ground to the minimum size.

Not only the safety factor of the blade is high, but also the production efficiency can be significantly improved and the cutting cost can be reduced.

PRECISION TOLERANCE ASSURANCE

Goodklife cutting blades are more like works of art. The company currently has a number of ultra fine grinding machines and a

utomatic R-type grinding machine

. Every employee in the finishing workshop is deeply rooted in the pursuit of high precision, and strictly abides by the operating system to ensure that every shearing blade is qualified.

GOODKLIFE BRAND STORY

COMPANY PROFILE

GOODKLIFE HISTORY

1988 As one of the first companies producing metal shear processing tools in China, we have been continuously exploring high quality products.

2006 Successfully developed a new tool high-strength steel G1, which greatly improved the service life of metalworking tools. The material was awarded the national new invention patent in 2008.

2011 We started to enter the international market, and now our products are selling well in many countries.

HIGH PRECISION TOLERANCE

1998 Started production of slitting tools with a thickness accuracy of +/-0.005 mm.

2000 Started mass production of slitting tools with a thickness accuracy of +/-0.005 mm.

2003 Started mass production of slitting tools with a thickness of +/-0.003 mm.

2016 We started mass production of slitting tools with thickness +/-0.001 mm and parallelism and flatness 0.002 mm accuracy.

Hot Searches