- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Xinglong

-

Dimension(L*W*H):

-

customized

-

Weight:

-

abouot 2T

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support

-

speed:

-

you like

-

color:

-

customized

-

type:

-

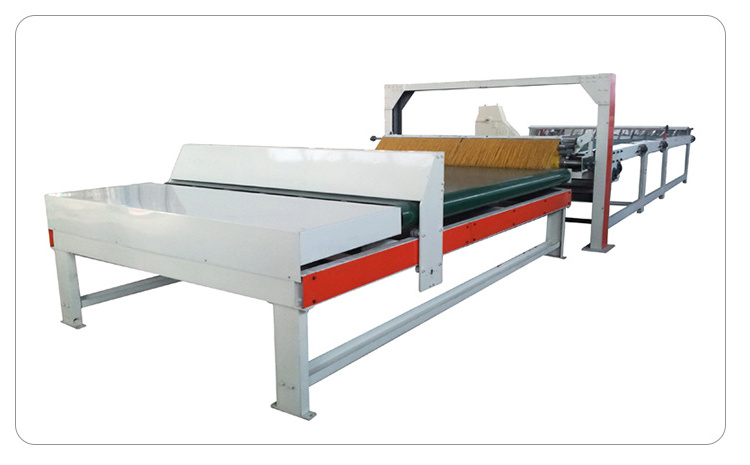

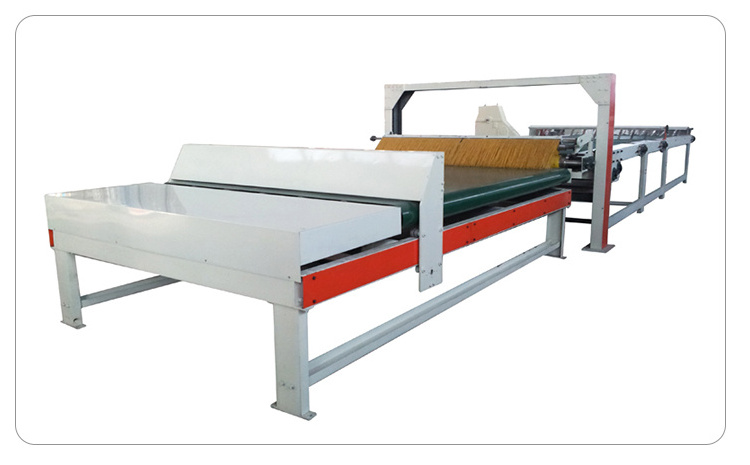

Automatic corrugated cardboard stacker/stacking machine

-

package:

-

wooden cases, wooden pallets

-

warranty:

-

1 year

-

Certification:

-

CE

Quick Details

-

Application:

-

Food, Beverage, Commodity, Machinery & Hardware, APPAREL, Textiles

-

Packaging Material:

-

Plastic

-

Voltage:

-

380V50Hz 3 phase

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Xinglong

-

Dimension(L*W*H):

-

customized

-

Weight:

-

abouot 2T

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support

-

speed:

-

you like

-

color:

-

customized

-

type:

-

Automatic corrugated cardboard stacker/stacking machine

-

package:

-

wooden cases, wooden pallets

-

warranty:

-

1 year

-

Certification:

-

CE

Ø Features:

1. Change order in 5 seconds, automatic counting and automatic horizontal paperboard delivery.

4. Stacking platform, AC servo control movements, stacking smoothly and tidily.

5. Automatic paperboard side delivery when reach the setting quantity.

6. Paperboard dam controlled by AC servo system, change order automatic and fast, suitable for small size paperboard stacking.

7. Standard electric transport conveyor and double side delivery table.

8. Individually sealed control cabinet, electrical running in clean environment.

9. Color touch-screen display for easy field operation.

10. Automatic operation control, improve efficiency, save manpower, reduce labor intensity.

11. Adopted on the 16th channel welded.Electric adjustment of cardboard the size of the lateral output pneumatic control board, electrically adjustable conveyor speed.

12. Cardboard sheets to the desired number or height requirements will be controlled by a foot switch out of cardboard.

13. Vertical bin using wide flat belt conveyor transport

14. Three section belt structure ,independent frequency motor driving .

15. Follow the production line automatically and can adjusting the speed .

16. Control unit adopt high quality human-computer interface and contolled by the PLC .

17. Finish the paperboard transport ,batch ,stack and counter exactly automatically.

18. The third part adopts pneumatic control and collects the paper with the lifting and falling ,the position of the

back baffle adopts electric and automatic adjustment to choose .

19. The paper adopts belt type to transmit and collects laterally, running smoothly and steady and easy maintaining

Ø Technical parameters:

| Max. Working width | 2000 | 2200 |

| Operation side | left or right ( depends on customer’s factory ) | |

| Max. Stacking height | 300mm | |

| Max stacking length | 3000 mm | |

| Adaptation production line speed | 130-150m/min | |

Ø Power motors and electrical parameters:

1.Main conveyor motor:3KW adopt frenquency motor

2.Lateral output of the motor:1.5KW Three-phase asynchronous motor

3.Walking Motor:1.5KW Three-phase asynchronous motor