- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

mosen

-

Dimension(L*W*H):

-

5000mm*2300mm*2400mm

-

Capacity:

-

6.3cbm

-

Weight:

-

2020

-

Inner Material:

-

Stainless steel

-

Outer Material:

-

c.s. steel

-

Design Pressure(MPa):

-

2MPA

-

Design Standard:

-

GB

-

Working Temperature(℃):

-

100 - 500 ℃

-

Product name:

-

Carbon Fiber Composite For Aviation Sorts Car Curing Autoclave

-

Material:

-

Q345R/Q370R Carbon Steel composite autoclave

-

Application:

-

Composite Material autoclave

-

Function:

-

High Temperature High Pressure composite autoclave

-

Name:

-

Carbon Fiber Composite For Aviation Sorts Car Curing Autoclave

-

Advantage:

-

High Efficiency composite autoclave

-

Key words:

-

Carbon Fiber Composite For Aviation Sorts Car Curing Autoclave

-

Certification:

-

ISO9001/CE/ASME composite autoclave

-

Package:

-

as customer standard composite autoclave

-

Standard:

-

GB150-2011 / ASME composite autoclave

Quick Details

-

Volume (m³):

-

6.3CBM

-

Max Working Pressure(MPa):

-

1.6MPA

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

mosen

-

Dimension(L*W*H):

-

5000mm*2300mm*2400mm

-

Capacity:

-

6.3cbm

-

Weight:

-

2020

-

Inner Material:

-

Stainless steel

-

Outer Material:

-

c.s. steel

-

Design Pressure(MPa):

-

2MPA

-

Design Standard:

-

GB

-

Working Temperature(℃):

-

100 - 500 ℃

-

Product name:

-

Carbon Fiber Composite For Aviation Sorts Car Curing Autoclave

-

Material:

-

Q345R/Q370R Carbon Steel composite autoclave

-

Application:

-

Composite Material autoclave

-

Function:

-

High Temperature High Pressure composite autoclave

-

Name:

-

Carbon Fiber Composite For Aviation Sorts Car Curing Autoclave

-

Advantage:

-

High Efficiency composite autoclave

-

Key words:

-

Carbon Fiber Composite For Aviation Sorts Car Curing Autoclave

-

Certification:

-

ISO9001/CE/ASME composite autoclave

-

Package:

-

as customer standard composite autoclave

-

Standard:

-

GB150-2011 / ASME composite autoclave

Continuous Industrial Prepreg Oven Laminated Glass Carbon Fiber Composite Curing Autoclave

Products Description

EQUIPMENT INTRODUCTION

1.Composite curing is a critical step in manufacturing quality composite materials. Traditionally, most composite parts required autoclaves for proper curing. Today, low cost out-of-autoclave curing of aerospace-grade composite parts is possible using a vacuum bagging system with a walk-in batch oven. The process is precisely controlled and monitored to ensure void-free composite parts.

2.Composite curing blanket and controller Composite materials are a two-part system that consists of a cloth fiber material and an epoxy resin. The epoxy resin bonds the cloth layers together and through a curing process, forms a strong and lightweight product. The term “pre-preg” is used to identify cloth materials that are pre-pregnated or pre-saturated with a resin. They are preferred over typical wet lay-ups because they provide less mess, less waste, faster cure time, better part uniformity, and better appearance. However, these pre-preg cloth materials can be challenging to fit into the sometimes complex shapes and contours of a

mold. Preheating the mold to approximately 120°F (49°C) softens the pre-preg cloth material as it is hand laid into the mold. The heat makes the cloth more malleable and easier to work along the sometimes complex geometries of the mold.

2.Composite curing blanket and controller Composite materials are a two-part system that consists of a cloth fiber material and an epoxy resin. The epoxy resin bonds the cloth layers together and through a curing process, forms a strong and lightweight product. The term “pre-preg” is used to identify cloth materials that are pre-pregnated or pre-saturated with a resin. They are preferred over typical wet lay-ups because they provide less mess, less waste, faster cure time, better part uniformity, and better appearance. However, these pre-preg cloth materials can be challenging to fit into the sometimes complex shapes and contours of a

mold. Preheating the mold to approximately 120°F (49°C) softens the pre-preg cloth material as it is hand laid into the mold. The heat makes the cloth more malleable and easier to work along the sometimes complex geometries of the mold.

Specification

|

TYPE

|

1600*2500

|

2000*3500

|

2500*5500

|

3000*6500

|

3500*7500

|

4000*8500

|

|

Max pressure

|

3.8MPA

|

1.0MPA

|

1.0MPA

|

1.5MPA

|

1.2MPA

|

1.2MPA

|

|

Design pressure

|

4MPA

|

1.2MPA

|

1.2MPA

|

1.6MPA

|

1.3MPA

|

1.3MPA

|

|

Max temperature

|

400℃

|

250℃

|

250℃

|

250℃

|

250℃

|

250℃

|

|

Design temperature

|

420℃

|

270℃

|

270℃

|

270℃

|

270℃

|

270℃

|

|

Insulation

|

Internal 200mm

|

Internal 150mm

|

Internal 150mm

|

Internal 150mm

|

Internal 150mm

|

Internal 150mm

|

|

Total power

|

60kw

|

90kw

|

210kw

|

330kw

|

510kw

|

780kw

|

Continuous Industrial Prepreg Oven Laminated Glass Carbon Fiber Composite Curing Autoclave

EQUIPMENT FEATURES

1. PLC control

2. Electrical Curing recommended (Far-infrared heating internative)

3. Water cooling system

4. Air cycle system

5. Meet CE International Standard

2. Electrical Curing recommended (Far-infrared heating internative)

3. Water cooling system

4. Air cycle system

5. Meet CE International Standard

Autoclave Characters

1. Electric curing ensure effective heating all around the interior chamber.

2. Motor fans make air evenly circulation for temperature distribution better.

3. Double channel PLC control system, alternative control channel guarantee the presetted

process progressive while the autoclave accident happens.

4. Vacuum port connect with the vacuum bags pressure, control and detecting independent.

5. Interior air circulation system

6. Chamber and motor cooling system

7. Auto door leaf with oil cylinder control

8. Each vacuum port independent control and detecting

9. Temperature ,pressure and time pre-setted and adjustable

10. Interior and outside Insulation

Autoclave specification need to confirm with you, diameter ,length ,pressure ,temperature ect .

2. Motor fans make air evenly circulation for temperature distribution better.

3. Double channel PLC control system, alternative control channel guarantee the presetted

process progressive while the autoclave accident happens.

4. Vacuum port connect with the vacuum bags pressure, control and detecting independent.

5. Interior air circulation system

6. Chamber and motor cooling system

7. Auto door leaf with oil cylinder control

8. Each vacuum port independent control and detecting

9. Temperature ,pressure and time pre-setted and adjustable

10. Interior and outside Insulation

Autoclave specification need to confirm with you, diameter ,length ,pressure ,temperature ect .

Product application

This equipment is mainly for carbon fiber materials carbon plates, pipe fittings, auto parts, sporting goods, helmets, aerospace accessories, high temperature and high pressure curing molding, autoclaves are currently used in the composite products industry curing molding is far better than vacuum flow technology, molding technology.

Why Choose Us

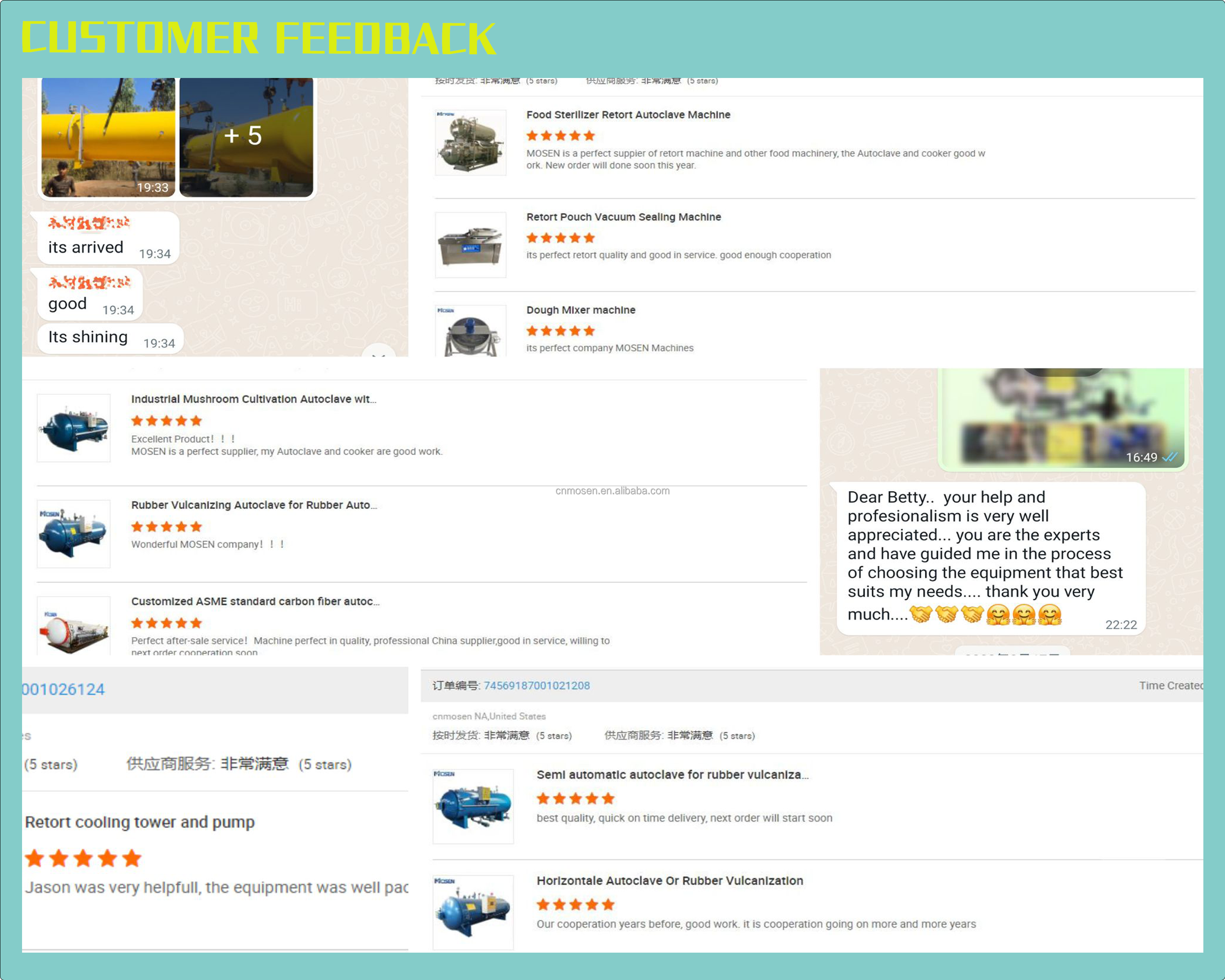

Customer Photos

After-sales Service

Packaging

FAQ

Q: Are you the autoclave manufacturer or trading company?

A: We are a professional manufacturer.

Q: What is your business scope?

A: There are three categories, such as rubber vulcanization autoclave,food sterilization machine, jacket cooker.

Q: How about the autoclave installation? And what if the autoclave machine goes down?

A: We wil l do that. There are two options.

a. We could appoint our engineer to your company to debug and repair, as for the cost of this trip such as ticket, visa,

accommodation and labor cost shall be on your side.

b. On-line service will be provided. If still is under guarantee period, the necessary accessories and parts will be provided

free, but the transportation cost of it shall be on your side.

Q: Do you take L/C?

A: Yes, we accept L/C, T/T and irrevocable L/C payable.

If you want to know more about our industrial rubber autoclave , welcome to our company for detailed information. Here we have professional engineers and technicians to instruct you.

A: We are a professional manufacturer.

Q: What is your business scope?

A: There are three categories, such as rubber vulcanization autoclave,food sterilization machine, jacket cooker.

Q: How about the autoclave installation? And what if the autoclave machine goes down?

A: We wil l do that. There are two options.

a. We could appoint our engineer to your company to debug and repair, as for the cost of this trip such as ticket, visa,

accommodation and labor cost shall be on your side.

b. On-line service will be provided. If still is under guarantee period, the necessary accessories and parts will be provided

free, but the transportation cost of it shall be on your side.

Q: Do you take L/C?

A: Yes, we accept L/C, T/T and irrevocable L/C payable.

If you want to know more about our industrial rubber autoclave , welcome to our company for detailed information. Here we have professional engineers and technicians to instruct you.

Contact us

Hot Searches