- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Single layer corrugated hose making machine

-

Voltage:

-

380v 50hz

-

Dimension(L*W*H):

-

10*2*2m

-

Power (kW):

-

100

-

Weight:

-

4000 KG

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

30:1

-

Screw Speed (rpm):

-

90 rpm

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Single layer corrugated hose making machine

-

Voltage:

-

380v 50hz

-

Dimension(L*W*H):

-

10*2*2m

-

Power (kW):

-

100

-

Weight:

-

4000 KG

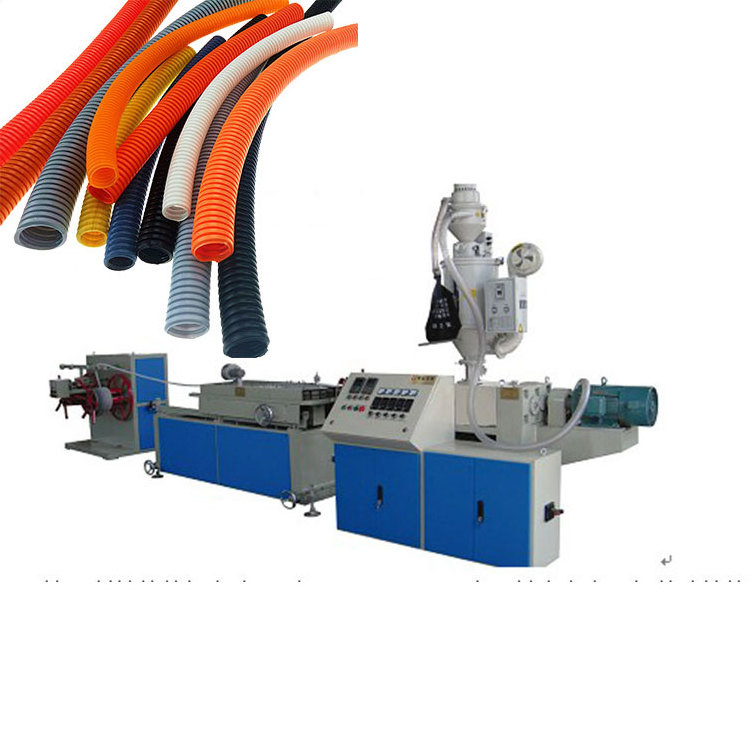

PVC PE PP PA SINGLE LA CORRUGATED HOSE MAKING MACHINE

1. Introduction of PVC single wall corrugated pipe machine

Different extruder and forming machine will be chosen for different material: PA, PE, PP, UPVC, etc. The pipe is mainly use for electrical cable or wire protection, drainage pipe of washing machine, pipe in dust collector, automobile industry, lamp industry and air-exhausted pipe etc.

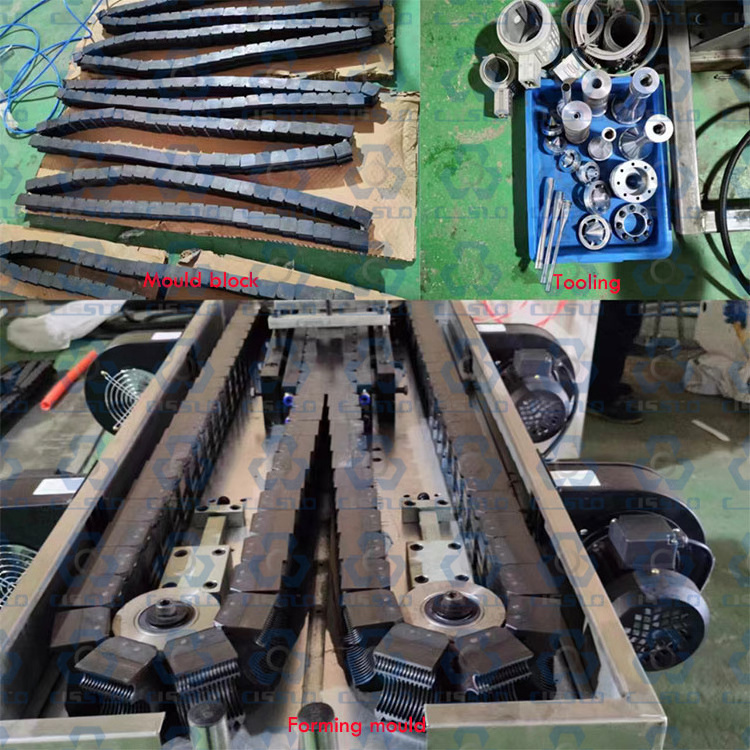

Standard single wall high speed corrugated pipe forming machine: can produce two diameters or three diameters’ single wall corrugated pipe in the same mould blocks, which reduce the cost of the moulds and reduce the time for changing the mould blocks, increase the efficiency.

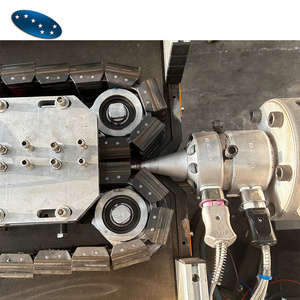

High speed corrugated pipe forming machine: forming blocks running without chain, blocks installed directly in the gear groove, rely on 9Mn2V material forming blocks with machining accuracy of 0.01 mm, realize high speed stable running.

2. Material of PVC single wall corrugated pipe machine

- Material: PA, temperature range: -40°C-115°C, the product does not contain halide, anti-oil, anti-acid. Anti-inflammation rate is HB (U94). The black color pipe is ultraviolet resistant.

- Material: PP, temperature range: -20°C-110°C, the product is anti-oil, anti-acid, anti-alkali. The black color pipe is ultraviolet resistant.

- Material: PE, temperature range: -40°C-80°C, the product is anti-oil, anti-acid, anti-alkali. The black color pipe is ultraviolet resistant.

3. Main technical parameter of PVC single wall corrugated pipe machine

|

Model |

DBWG-45 |

DBWG-50 |

DBWG-65 |

DBWG-90 |

|

Screw diameter(mm) |

45 |

50 |

65 |

90 |

|

L/D |

30 |

30 |

30 |

30 |

|

Pipe diameter range(mm) |

4.5-13 |

16-32 |

25-48 |

90-160 |

|

Mold block quantity (pairs) |

52-70 |

52-70 |

52-60 |

72 |

|

Production speed (m/min) |

16-20 |

12-16 |

6-10 |

2-4 |

|

High speed type |

Model |

Screw diameter(mm) |

Pipe diameter range(mm) |

Production speed (m/min) |

|

DBWG-50T |

50 |

7-32 |

20-25 |

|

|

DBWG-45T |

45 |

5-25 |

20-25 |

4. Configuration of PVC single wall corrugated pipe machine

| NO. | Description | QTY |

| 1 | Vacuum feeder and hopper loader | 1set |

| 2 | Single Screw Extruder | 1set |

| 3 | Die Head(13mm-50mm) | 1set |

| 4 | Pipe Forming Machine with online cutter | 1set |

| 5 | Double station winding machine | 1set |

| 6 | Corrugated pipe perforation machine | 1set |

| 7 | Free Spare parts | 1set |

| 8 | Extra mould with month mould and core bar | 1set |

5. Pictures of PVC single wall corrugated pipe machine: