- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

1.6Kw

-

Dimension(L*W*H):

-

customized

-

Weight:

-

380 KG

-

Marketing Type:

-

New Product 2022

-

Product Name:

-

Beer Liquid Fermenter

-

Tank pressure:

-

0.2Mpa

-

Jacket pressure:

-

0.3Mpa

-

Volume:

-

100L-30000L

-

Capacity in liters:

-

100L -30000L

-

Material:

-

SUS304/SUS316/red Copper

-

Thickness of Tanks:

-

Inner 3mm/ Outer 2mm

-

Number of stirrer blades:

-

2pcs-4pcs

-

After-sales Service Provided:

-

Overseas Service Center

-

Control system:

-

PLC Control System

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Zhongyilong

-

Processing Types:

-

Milk,Beer,Daily chemical industry

-

Voltage:

-

380V

-

Power:

-

1.6Kw

-

Dimension(L*W*H):

-

customized

-

Weight:

-

380 KG

-

Marketing Type:

-

New Product 2022

-

Product Name:

-

Beer Liquid Fermenter

-

Tank pressure:

-

0.2Mpa

-

Jacket pressure:

-

0.3Mpa

-

Volume:

-

100L-30000L

-

Capacity in liters:

-

100L -30000L

-

Material:

-

SUS304/SUS316/red Copper

-

Thickness of Tanks:

-

Inner 3mm/ Outer 2mm

-

Number of stirrer blades:

-

2pcs-4pcs

-

After-sales Service Provided:

-

Overseas Service Center

-

Control system:

-

PLC Control System

Product Description

Specification

|

Item

|

Production capacity

|

Volume in US Gallon

|

Heating area

|

Tank diameter

|

Height

|

|

ZYL-500

|

500L/day

|

132US Gallon

|

0.5㎡

|

1160mm

|

2800mm

|

|

ZYL-600

|

600L/day

|

158US Gallon

|

0.6㎡

|

1220mm

|

2350mm

|

|

ZYL-700

|

700L/day

|

185US Gallon

|

0.7㎡

|

1250mm

|

2380mm

|

|

ZYL-800

|

800L/day

|

212 US Gallon

|

0.8㎡

|

1260mm

|

2400mm

|

|

ZYL-1000

|

1000L/day

|

264US Gallon

|

1.0㎡

|

1360mm

|

3000mm

|

|

ZYL-1500

|

1500L/day

|

396US Gallon

|

1.5㎡

|

1520mm

|

2900mm

|

|

ZYL-2000

|

2000L/day

|

528US Gallon

|

2.0㎡

|

1760mm

|

3150mm

|

|

ZYL-2500

|

2500L/day

|

660US Gallon

|

2.5㎡

|

1800mm

|

3200mm

|

|

ZYL-3000

|

3000L/day

|

792US Gallon

|

3.0㎡

|

1860mm

|

3800mm

|

|

ZYL-5000

|

5000L/day

|

1320US Gallon

|

5.0㎡

|

2260mm

|

4400mm

|

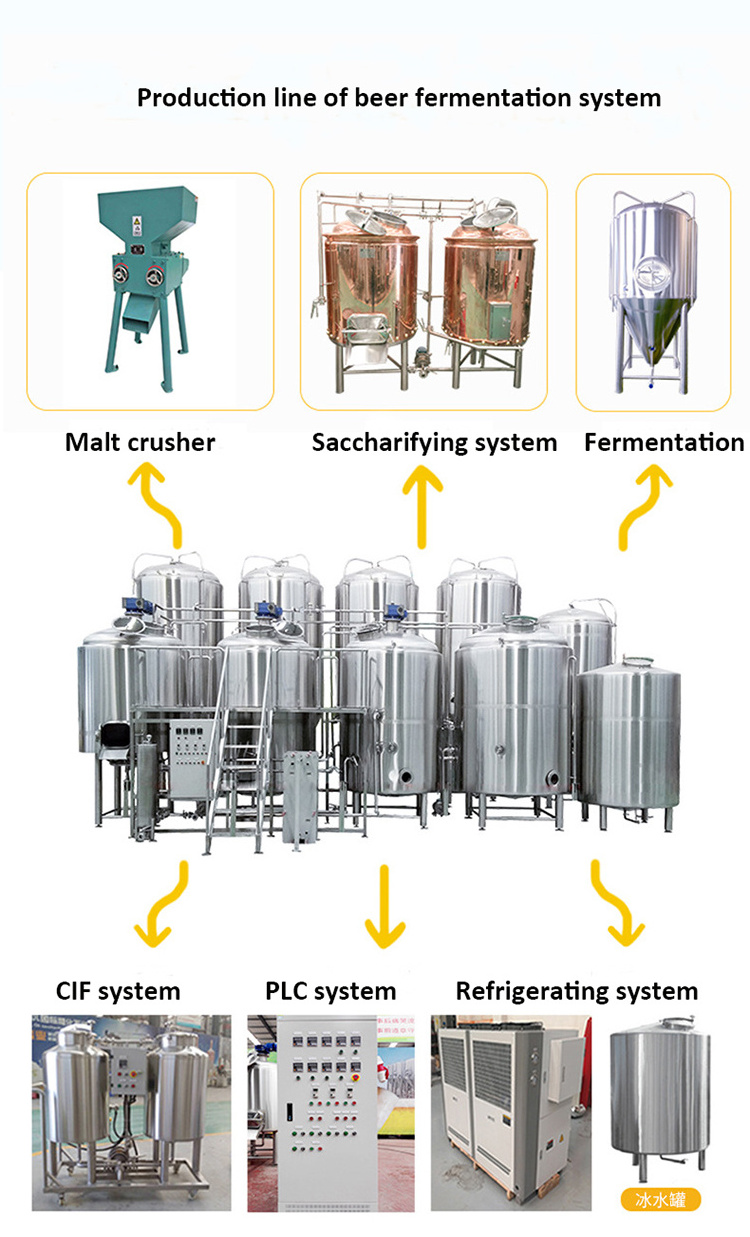

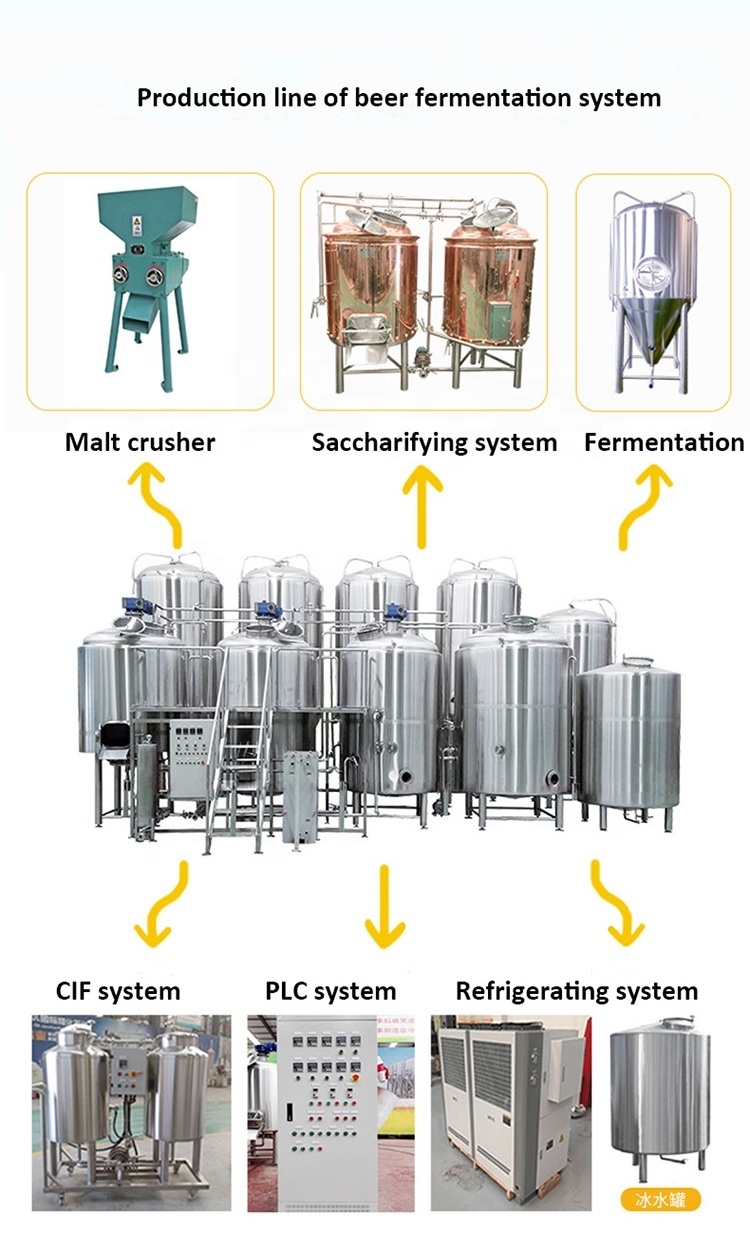

Features:

1.High cost performance.Good abrasion resistance material of the copper.

2.CIP cleaning system.

3.SUS304 material. The inner jacket and seal head of the tanks are all 3.0mm. The external jacket is 2.0mm. It ensure the good pressure resistance and good abrasion resistance.

4.Polishing accuracy up to Ra0.4μ m .

5.Strict tank pressure test.

2.CIP cleaning system.

3.SUS304 material. The inner jacket and seal head of the tanks are all 3.0mm. The external jacket is 2.0mm. It ensure the good pressure resistance and good abrasion resistance.

4.Polishing accuracy up to Ra0.4μ m .

5.Strict tank pressure test.

Product details

Related Products

About us

FAQ

Q1: Where is your factory? How can I visit your factory?

A: Our factory is located in Henan Province. If you have a travel plan, we warmly welcome you to visit our factory.

Q2: Can you send me a video to show me how the machine works?

A: Of course, we made videos of each machine.

Q3: How do I know your machine is designed for my product?

A: You can send us your product samples, and we will test them on the machine.

Q4: How do I pay for my order?

Answer: Usually we accept L/C, D/A, D/P, T/T, Western Union, Money Gram and cash payment .

Q5: Do you have a Ce certificate?

A: For each model of machine, it has CE certification

Q2: Can you send me a video to show me how the machine works?

A: Of course, we made videos of each machine.

Q3: How do I know your machine is designed for my product?

A: You can send us your product samples, and we will test them on the machine.

Q4: How do I pay for my order?

Answer: Usually we accept L/C, D/A, D/P, T/T, Western Union, Money Gram and cash payment .

Q5: Do you have a Ce certificate?

A: For each model of machine, it has CE certification

Hot Searches