- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

7.5

-

Weight (KG):

-

11000

-

Product name:

-

Scrap metal press machine

-

After-sales Service Provided:

-

Online Support

-

Application:

-

Press Scrap Metal

-

Keyword:

-

Horizontal Metal Baler

-

Material:

-

Steel Material

-

Model:

-

Electric

-

Color:

-

Customer's Requirement

-

Capacity:

-

800-1500kg/h

-

Material box size:

-

1000*600*500

-

Motor Power:

-

7.5 Kw

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FuDe

-

Model Number:

-

FD-630

-

Power (kW):

-

7.5

-

Weight (KG):

-

11000

-

Product name:

-

Scrap metal press machine

-

After-sales Service Provided:

-

Online Support

-

Application:

-

Press Scrap Metal

-

Keyword:

-

Horizontal Metal Baler

-

Material:

-

Steel Material

-

Model:

-

Electric

-

Color:

-

Customer's Requirement

-

Capacity:

-

800-1500kg/h

-

Material box size:

-

1000*600*500

-

Motor Power:

-

7.5 Kw

Product Overview

waste copper aluminum press and baling machine Strap compactor Manufacturing Machines Scrap metal press machine

Hydraulic Baler is mainly used for packing all kinds of light and thin waste in cold state burdle blocks to form a compact cuboid block,which is convenient for storage and transportation. Its the ideal equipment for metal scrap treatment in steel plants,non-ferrous metal plants and smelting plants.W

aste copper aluminum press and baling machine Strap compactor Manufacturing Machines Scrap metal press machine

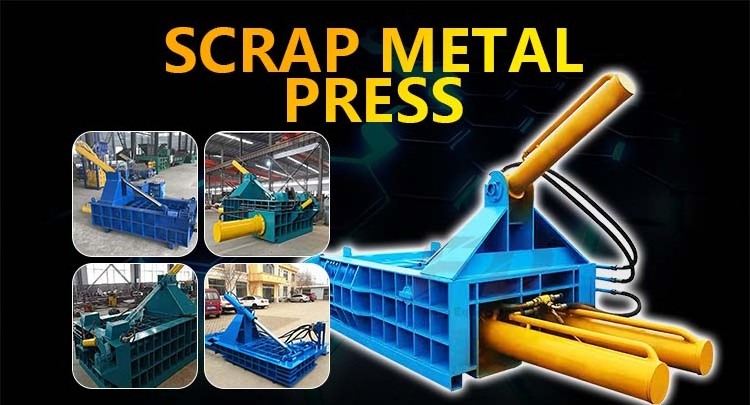

FEATURES AT A GLANCE

The Ziptop Can Compressing Machinery Scrap Iron Aluminum Metal Baler is used to compress scrap metal(steel, copper,aluminum,stainless steel, etc)into metal block or metal bale. The purpose is to save the transportation cost or reduce the raw material loss when smelting.W

aste copper aluminum press and baling machine Strap compactor Manufacturing Machines Scrap metal press machine

PRODUCT SPECIFICATIONS

1. Put the prepared raw materials into the machine inlet

2. Start the control rocker to squeeze the raw materials

3. The main hydraulic cylinder first pushes and compacts the raw materials, and the side hydraulic cylinders are again pressed and compacted.

4. The pressed material is in the shape you want and is pushed out from the discharge port.

5. The processed materials have the same volume and size, meet the packaging standards, and are convenient for transportation and storage.

2. Start the control rocker to squeeze the raw materials

3. The main hydraulic cylinder first pushes and compacts the raw materials, and the side hydraulic cylinders are again pressed and compacted.

4. The pressed material is in the shape you want and is pushed out from the discharge port.

5. The processed materials have the same volume and size, meet the packaging standards, and are convenient for transportation and storage.

|

Model

|

Power(KW)

|

Presure(kn)

|

Press room(mm)

|

Bloke size(mm)

|

Capacity(kg/h)

|

|

FD-630

|

7.5

|

630

|

1000*600*500

|

200*200

|

800-1500

|

|

FD-1000

|

11

|

1000

|

1000*700*550

|

250*250

|

1000-1800

|

|

FD-1300

|

15

|

1300

|

1200*700*600

|

300*300

|

1000-2000

|

|

FD-1600

|

22

|

1600

|

1200*1000*800

|

400*400

|

2000-3000

|

|

FD-2000

|

37

|

2000

|

1800*1200*900

|

500*500

|

3000-5000

|

|

FD-2500

|

44

|

2500

|

2000*1400*900

|

500*500

|

5000-6500

|

|

FD-3150

|

60

|

3150

|

2000*1750*1200

|

600*600

|

6500-7500

|

PRODUCT CONFIGURATION

FINISHED PRODUCT DISPLAY

Mainly used in recycling processing industry and metal smelting industry. Various metal scraps, steel shavings, scrap steel, scrap iron, scrap copper, aluminum scrap, aluminum shavings, dismantled car shells, waste oil drums and other metal materials can be

extruded into various shapes of qualified materials such as cubes and cylinders. . Easy to store, transport and recycle.

SIMILAR PRODUCTS

COMPANY PROFILE

Our company is an equipment manufacturing enterprise integrating R & D, production and sales of agricultural, forestry and construction machinery. With the development goal of "building a century old enterprise and forging an international brand", the company adheres to the business philosophy of "quality, innovation, integrity, harmony and win-win", and provides high-quality and efficient products and services for the society.

FAQ

Q1: Are you trading company or manufacturer?

A: We are factory.

Q2: How long is your delivery time?

A: Generally it is 7-10 days if the goods are in stock. Or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q3: What is your payment method?

A: 30% of total prices should be paid by T/T as down payment; 70% balance payment should b paid by T/T before delivery.

Q4: How long is the warrenty of your equipments? Does your company supply the spare parts?

A: The warranty period of crusher equipments is one year. And we will supply the spare parts for you at lowest cost.

Q5: If I need the complete crushing plant can you help us to build it?

A: Yes, we can help you set up a complete crushing line and give you related professional advices as long as you need. We had already build many mining projects in China & Oversea

Hot Searches