- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

epoxy resin industrial electronics adhesive glue

-

Material:

-

one-component potting materials

-

Storage temperature:

-

-20-8℃

-

Curing method:

-

Heat curing

-

Color:

-

Black

-

Product Description:

-

Suitable for low-temperature curing of heat-sensitive components

-

Curing system:

-

Heat cured or UV cured

-

Glue type:

-

Epoxy resin-based

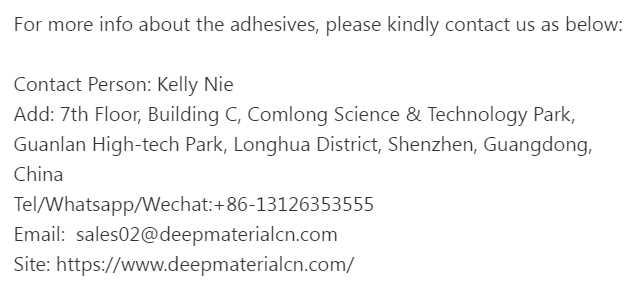

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

DeepMaterial

-

Model Number:

-

DM-6320

-

Product name:

-

epoxy resin industrial electronics adhesive glue

-

Material:

-

one-component potting materials

-

Storage temperature:

-

-20-8℃

-

Curing method:

-

Heat curing

-

Color:

-

Black

-

Product Description:

-

Suitable for low-temperature curing of heat-sensitive components

-

Curing system:

-

Heat cured or UV cured

-

Glue type:

-

Epoxy resin-based

Deepmaterial Best Top 10 Magnet Bonding Adhesives Manufacturers for Custom

Speaker Glue Optically Bonding In China

DeepMaterial offers new capillary flow underfills for flip chip, CSP and BGA devices. DeepMaterial's new capillary flow underfills are high fluidity, high-purity, one-component potting materials that form uniform, void-free underfill layers that improve the reliability and mechanical properties of components by eliminating stress caused by solder materials. DeepMaterial provides formulations for fast filling of very fine pitch parts, fast cure capability, long working and lifespan, as well as the reworkability. Reworkability saves costs by allowing removal of the underfill for reuse of the board.

Flip chip assembly requires stress relief of the welding seam again for extended thermal aging and cycle life. CSP or BGA assembly requires the use of an underfill to improve the mechanical integrity of the assembly during flex, vibration or drop testing.

DeepMaterial's flip-chip underfills have high filler content while maintaining fast flow in small pitches, with the ability to have high glass transition temperatures and high modulus. Our CSP underfills are available in varying filler levels, selected for the glass transition temperature and modulus for the intended application.

DeepMaterial COB encapsulating adhesives are formulated with heat-curing epoxy, UV-curing acrylic, or silicone chemistries for good electrical insulation. DeepMaterial COB encapsulating adhesives offer good high temperature stability and thermal shock resistance, electrical insulating properties over a wide temperature range, and low shrinkage, low stress, and chemical resistance when cured.

Underfill Epoxy Product Selection

|

Product Series |

Product name |

Product typical application |

|

Underfill |

DM-6307 |

It is a one-component, thermosetting epoxy resin. It is a reusable CSP (FBGA) or BGA filler used to protect solder joints from mechanical stress in handheld electronic devices. |

|

DM-6303 |

One-component epoxy resin adhesive is a filling resin that can be reused in CSP (FBGA) or BGA. It cures quickly as soon as it is heated. It is designed to provide good protection to prevent failure due to mechanical stress. Low viscosity allows filling gaps under CSP or BGA. |

|

|

DM-6309 |

It is a fast curing, fast flowing liquid epoxy resin designed for capillary flow filling chip size packages, is to improve the process speed in production and design its rheological design, let it penetrate 25μm clearance, minimize induced stress, improve temperature cycling performance, with excellent chemical resistance. |

|

|

DM- 6308 |

Classic underfill, ultra-low viscosity suitable for most underfill applications. |

|

|

DM-6310 |

The reusable epoxy primer is designed for CSP and BGA applications. It can be cured quickly at moderate temperatures to reduce the pressure on other parts. After curing, the material has excellent mechanical properties and can protect solder joints during thermal cycling. |

|

|

DM-6320 |

The reusable underfill is specially designed for CSP, WLCSP and BGA applications. Its formula is to cure quickly at moderate temperatures to reduce stress on other parts. The material has a higher glass transition temperature and higher fracture toughness, and can provide good protection for solder joints during thermal cycling. |

Underfill Epoxy Adhesive Product Data Sheet

|

Product line |

Product Series |

Product Name |

Colour |

Typical viscosity (cps) |

Initial fixation time / full fixation |

Curing method |

TG/°C |

Hardness /D |

Store/°C/M |

|

Epoxy based |

Underfill |

DM-6307 |

Black |

2000-4500 |

120°C 5min 100°C 10min |

Heat curing |

85 |

88 |

2-8/6M |

|

DM-6303 |

Opaque creamy yellow liquid |

3000-6000 |

100°C 30min 120°C 15min 150°C 10min |

Heat curing |

69 |

86 |

2-8/6M |

||

|

DM-6309 |

Black liquid |

3500-7000 |

165°C 3min 150°C 5min |

Heat curing |

110 |

88 |

2-8/6M |

||

|

DM-6308 |

Black liquid |

360 |

130°C 8min 150°C 5min |

Heat curing |

113 |

* |

-20/6M |

||

|

DM-6310 |

Black liquid |

394 |

130°C 8min |

Heat curing |

102 |

* |

-20/6M |

||

|

DM-6320 |

Black liquid |

340 |

130°C 10min 150°C 5min 160°C 3min |

Heat curing |

134 |

* |

-20/6M |

1. What’s the minimum order quantity(MOQ)?

- Minimum 1 unit, small batch and large volumes are acceptable.

2. When can I get the quotation?

- We usually respond within 24 hours on working days receiving your messages.

After we receive the TDS report or sample, we will forward to you with quotation within one week.

3. Which is the safe payment method to trade?

- We accept T/T, LC, Paypal, Trade Assurance and Secure payment on Alibaba platform.

4. How long does it take to deliver?

- For standard adhesive, it will be 7 days for manufacturing.

- For non-standard adhesive, it will be negotiated customized according to your requirements.

5. What’s the shipping method?

- We are able to ship worldwide where Ocean shipping or Air shipping can reach.

- We have a professional packaging team. Products will be packed safely and protectively.

Our Factory specializing in adhesives for semiconductor and electronic applications and surface protection materials for chip packaging and testing. Based on the core technology of adhesives, DeepMaterial has developed adhesives for chip packaging and testing, circuit board-level adhesives, and adhesives for electronic products. Based on adhesives, it has developed protective films, semiconductor fillers, and packaging materials for semiconductor wafer processing and chip packaging and testing. To provide electronic adhesives and thin-film electronic application materials products and solutions for communication terminal companies, consumer electronics companies, semiconductor packaging and testing companies, and communication equipment manufacturers,to solve the above-mentioned customers in process protection, product high-precision bonding, and electrical performance. Domestic substitution demand for protection, optical protection, etc.

The Factory continues to modify the application of adhesives and resin materials, and the company's strategic plan will focus on the development of EB curing adhesives and new semiconductor materials. EB curing adhesives and resins will break through the technical bottlenecks such as curing time, open operation time and bonding strength of any structural adhesive in the world, thereby forming no open time, no curing time (super fast nanosecond curing), high viscosity new adhesives with high bonding strength will break the current use of electronic products and component assembly, precision sensors, PCB circuit board substrate processing, PCB circuit board etching processing (etching process above 195nm), new energy (battery and wind power potting, bonding). The market adhesive application rules for the building materials industry (composite panels); the application of EB curing and irradiation technology in the direction of semiconductor materials will break through the current technological monopoly of semiconductor protective materials by Japanese companies and achieve technical overtaking on a curve.