1. Highest grinding efficiency

2. Increase the feed rate

3. High sharpness

4. Beautiful appearance

5. No trimming tools required

6. Less fever

7. Excellent dynamic balance control.

8. It can cut superhard workpieces.

- Product Details

- {{item.text}}

Quick Details

-

Size:

-

customized

-

Place of Origin:

-

China

-

Brand Name:

-

RZ

-

Model Number:

-

1A1,14A1, 6A2

-

Viscosity:

-

standard

-

Product name:

-

vitrified bond CBN grinding wheel

-

Material:

-

CBN + Vitrified Bond

-

Matrix:

-

Alumium,steel or as your request

-

Feature:

-

Long Life High Performance

-

Type:

-

for machining cast iron (alloy cast iron, chilled cast iron

-

Delivery:

-

10-20 Days

-

MOQ:

-

1PCS

-

Package:

-

Carton

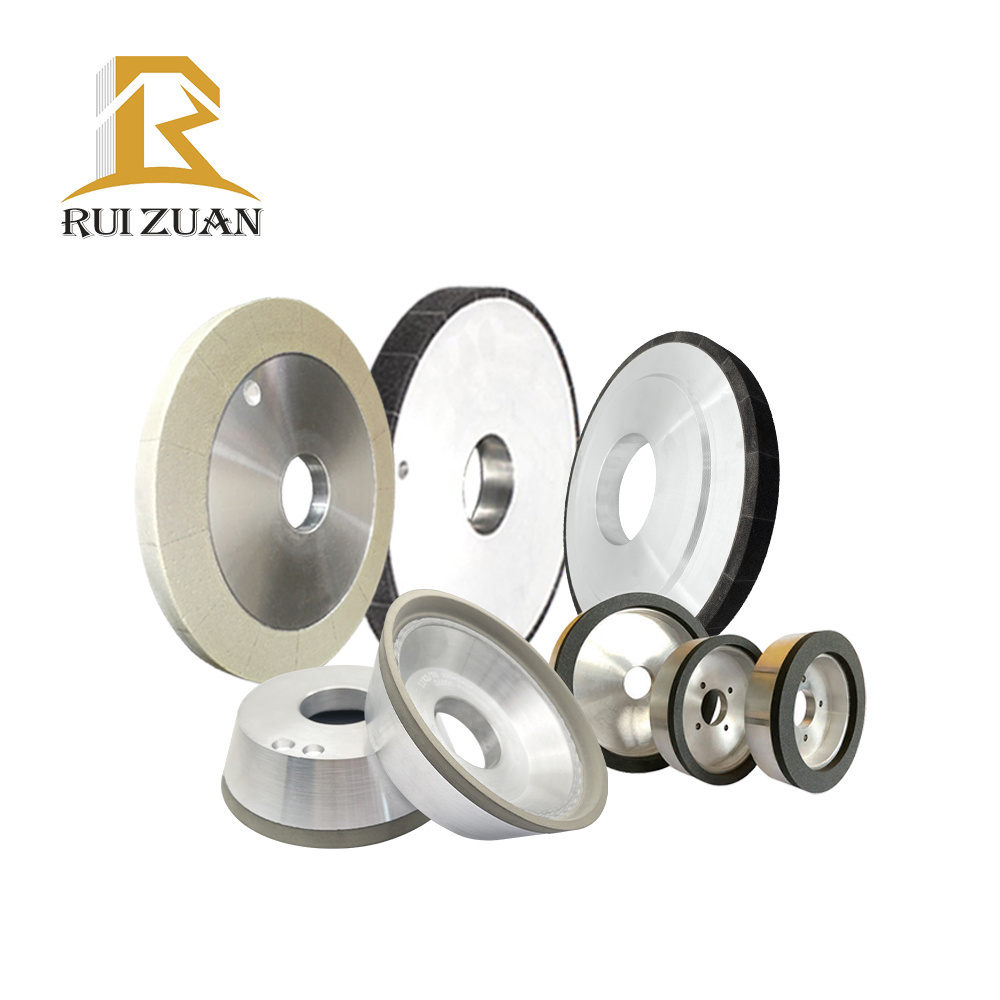

Quick Details

-

Application:

-

Aluminum, Deburring

-

Shape:

-

Flat-Shaped, Cup-Shaped, Bevel, bowl, cup, butterfly, flat grinding wheel, etc.

-

Hardness:

-

standard

-

Size:

-

customized

-

Place of Origin:

-

China

-

Brand Name:

-

RZ

-

Model Number:

-

1A1,14A1, 6A2

-

Viscosity:

-

standard

-

Product name:

-

vitrified bond CBN grinding wheel

-

Material:

-

CBN + Vitrified Bond

-

Matrix:

-

Alumium,steel or as your request

-

Feature:

-

Long Life High Performance

-

Type:

-

for machining cast iron (alloy cast iron, chilled cast iron

-

Delivery:

-

10-20 Days

-

MOQ:

-

1PCS

-

Package:

-

Carton

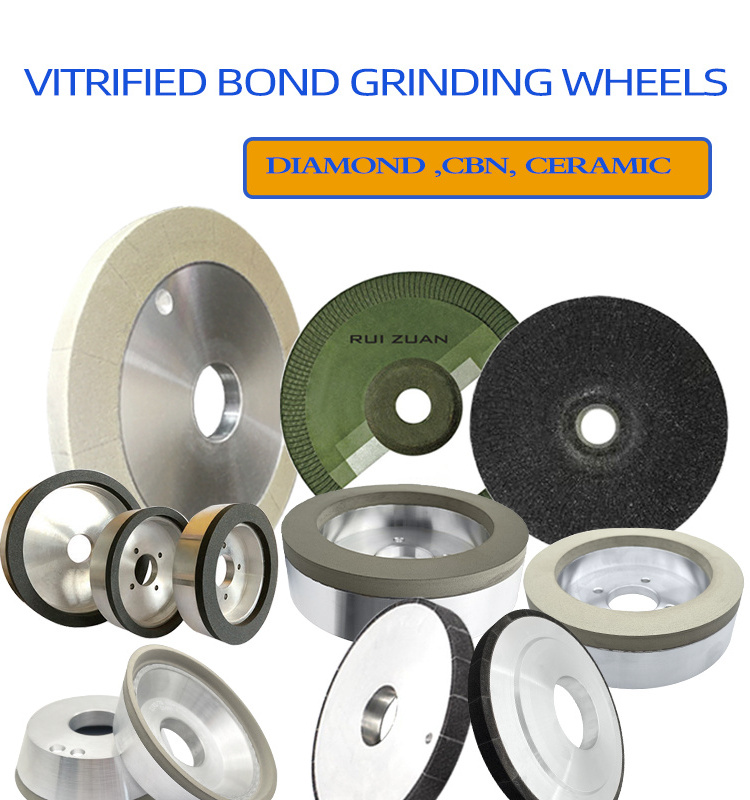

Products Description

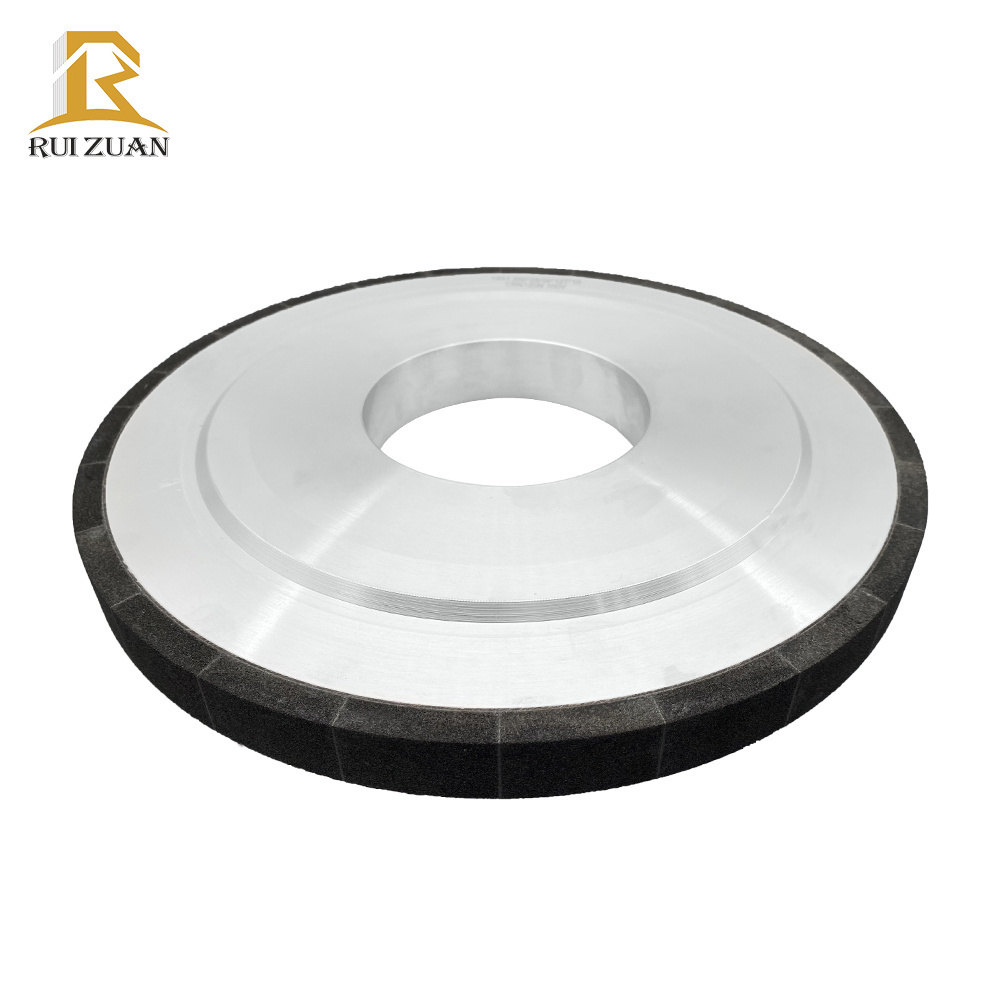

About the grinding wheel :

Vitrified bonds allow the wheel to be very rigid, strong and porous. These characteristics each provide many benefits to the wheel. Having a rigid wheel allows for a strong cutting performance and increased grinding speed. Another added benefit of the vitrified bond is its porous character. The porosity of the wheel allows coolant to penetrate between the work piece and the wheel to effectively remove heat from the point of contact, and we all know that any reduction in heat generated while grinding will extend the life of the product.

Advantages

Product Feature

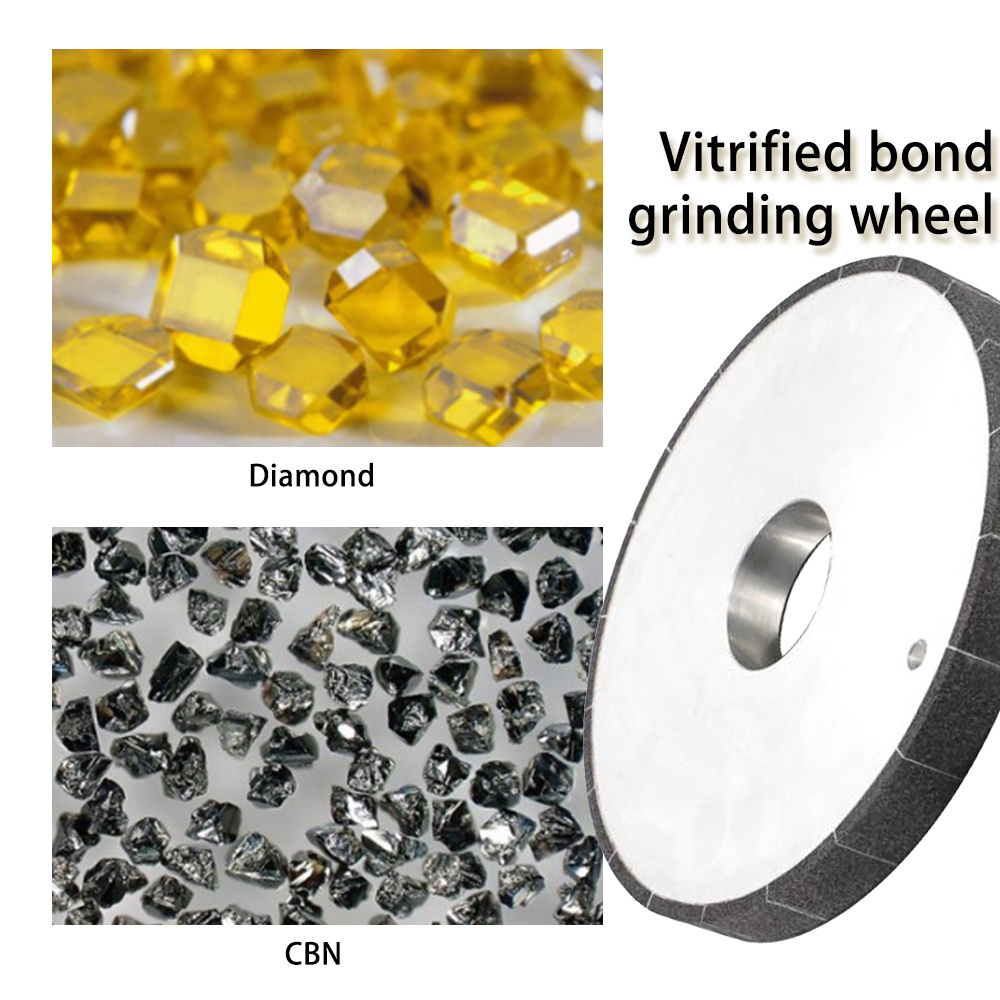

Abrasives

Generally, Diamond and CBN are called “Super Abrasives” or “Superhard Materials”. Obviously, the wheels manufactured with theseabravises are called Diamond or CBN grinding Wheels.

Diamond

CBN

Performance on grit sizes:

|

Code

|

Applicability

|

|

MD-20

|

fine polishing,perfect shining performance for polishing small diamond(10,20 pointers-1carat), with long life.

|

|

MD-40/60

|

rough polishing,high efficiency for polishing

|

|

MD-80/100/120

|

rougher polishing, higher efficiency, sharper cutting for bigger stones.(2,3 carat etc.)

|

Regular Model

In addition to regular models, we also accept custom models.

Application

* Vitrified Bond

Diamond

Grinding Wheels

1. - For PCD, PCBN super-hard cutting tools grinding

2. - For PCBN cutting tools grinding

3. - For CVD cutting tools grinding

4. -For single natural diamond tools grinding

5. - For polycrystalline diamond compacts ( PDC ) grinding 6. - For carbide alloy products grinding

7. - For ceramic product grinding

Why Choose Us

International Leading Trade Fair

for Grinding Technology

Hot Searches