- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

OEM

-

Liquid Flow Rate:

-

Max

-

Maximum Working Pressure:

-

4.5 mpa

-

Weight:

-

30 KG

-

Dimension(L*W*H):

-

Customized

-

Working Temperature Range:

-

/

-

Product name:

-

Heat Exchanger

-

Application:

-

heavy industry cooling and heating

-

Tube material:

-

Copper, SS, Titanium, Cu-Ni

-

Fin material:

-

Aluminum, Copper, SS

-

Frame material:

-

Galvanized, Galvanize steel, SS

-

Liquid in tube:

-

Regrigerant, Oil, Glycol, Impure liquid

-

Tube diameter:

-

5mm/7mm/7.94mm/9.52mm/12.75mm/15.88mm

-

Fin painting:

-

Hydrophilic aluminum foil, Golden fin, E-coating.....

-

Packing:

-

Export standard solid wood packing

-

Connection type:

-

Thread, Flange

Quick Details

-

Structure:

-

Tube Heat Exchanger

-

Voltage:

-

220v/380v/440v

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

OEM

-

Liquid Flow Rate:

-

Max

-

Maximum Working Pressure:

-

4.5 mpa

-

Weight:

-

30 KG

-

Dimension(L*W*H):

-

Customized

-

Working Temperature Range:

-

/

-

Product name:

-

Heat Exchanger

-

Application:

-

heavy industry cooling and heating

-

Tube material:

-

Copper, SS, Titanium, Cu-Ni

-

Fin material:

-

Aluminum, Copper, SS

-

Frame material:

-

Galvanized, Galvanize steel, SS

-

Liquid in tube:

-

Regrigerant, Oil, Glycol, Impure liquid

-

Tube diameter:

-

5mm/7mm/7.94mm/9.52mm/12.75mm/15.88mm

-

Fin painting:

-

Hydrophilic aluminum foil, Golden fin, E-coating.....

-

Packing:

-

Export standard solid wood packing

-

Connection type:

-

Thread, Flange

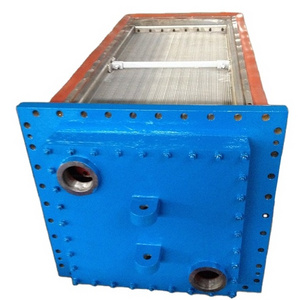

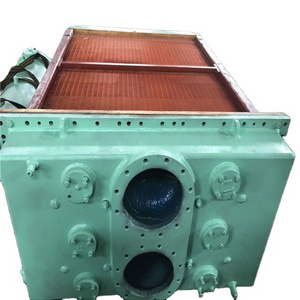

Products Description

Air compressor cooler

The energy produced by the compression process behaves as heat. The heat is removed before use (or further compression), thus requiring a pre-cooler, intercooler and aftercooler.

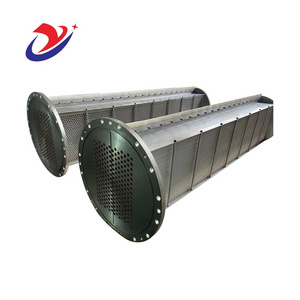

Inter cooler:

Most industrial compressors currently in operation are multi-stage designs. In order to optimize the cost of compressed gas, it is common to use multi-stage industrial compressors. When the air compressor compresses air, heat is generated, which causes the air to expand, and it is necessary to increase the HP for further air compression. It is suitable for the first and second stages of a multi-stage air compressor. The function of the compressor intercooler is to provide cooler, drier, and denser air for the next stage of compression.

After cooler:

The cooler is followed by a heat exchanger that removes heat from the compressed air. The most common compressor after the cooler uses cold ambient air or cold water to remove heat, which also effectively removes moisture from the compressed air.

Oil cooler:

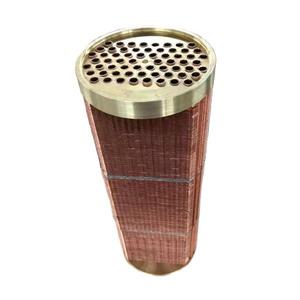

The purpose of the engine oil cooler is to allow the engine's cooling system to remove excess heat from the oil. These types of coolers are usually of the water-to-oil type of heat exchanger. ... The oil then flows through the tubes of the cooler while the engine coolant flows around the tubes.

Detailed introduction:

A cooler is a heat exchange device used to cool fluids. Typically, water or air is used as the coolant to remove heat. There are partition coolers, spray coolers, jacket coolers and coil coolers. It is widely used in large electrical equipment such as high-power silicon rectifiers, induction furnaces and intermediate frequency furnaces, and is equipped with pure water, water-air, oil-water, and oil-air cooling devices as cooling protection equipment.

The main objects of coolers are partition walls, hybrid and regenerative exchangers. The working principle of the cooler, heat transfer calculations, structural calculations, flow resistance calculations and design procedures are explained in detail in the Heat Exchanger book with detailed example problems.

Note on usage

(1) When the cooler is put into use, the exhaust valve on the cooling pipeline should be opened, drained, and closed after water is seen to prevent air resistance from affecting the cooling effect.

(2) When the cooler stops running and sweeps through the pipeline, the cooling water will stop and the cooling water discharge valve will be opened to prevent pressure damage to the equipment.

(3) When adjusting the oil temperature after cooling, the cooling water outlet valve should be controlled first. Since the water inlet valve is used to control the water volume, although cold water can be saved, it will cause a short circuit of the water flow or a slow flow rate in the cooler, resulting in heating and cooling, affecting the heat exchange effect. Therefore, access control should not be used.

Factory Photos

Inspection&Packing

Why Choose Us

Our main products:

Commercial heat exchanger

Industrial heat exchanger

Dry cooler

Unit cooler

Charge air cooler

Ingersoll Rand compressor interstage cooler,Compressor cooler(intercooler, aftercooler, oil cooler)

Contact Us

Sunny Yang

Mob:

+86 15690122018

Whatsapp:

+86 15690122018

Wechat:15690122018

Skype:info@datangpipe.com

Email:info@datangpipe.com

Hot Searches