- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Fullwin

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

CAPACITY

-

Power (kW):

-

50

-

Weight:

-

2000 KG

-

Motor:

-

AC Motor

-

Motor brand:

-

Siemnes

-

Contactor:

-

Siemens Contactor

-

Inverter:

-

ABB Brand

-

Product name:

-

single wall corrugated pipe machine

-

Test machine video:

-

Provide

-

Test machine report:

-

Provide

-

Certificate:

-

CE ISO

-

Keywords:

-

corrugated pipe Extrusion Machine

-

Original:

-

Qingdao ,China

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

30:1

-

Screw Speed (rpm):

-

90 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Fullwin

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

CAPACITY

-

Power (kW):

-

50

-

Weight:

-

2000 KG

-

Motor:

-

AC Motor

-

Motor brand:

-

Siemnes

-

Contactor:

-

Siemens Contactor

-

Inverter:

-

ABB Brand

-

Product name:

-

single wall corrugated pipe machine

-

Test machine video:

-

Provide

-

Test machine report:

-

Provide

-

Certificate:

-

CE ISO

-

Keywords:

-

corrugated pipe Extrusion Machine

-

Original:

-

Qingdao ,China

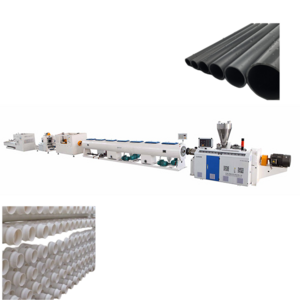

High speed single-wall corrugated pipe machine

FULLWIN plastic single-wall corrugated pipe production line developed by our company adopts gears to run moulds and templates so as to realize water circulating cooling air of the products,which ensures high-speed moulding,even corrugation,smooth inner and outer pipe wall.these corrugated pipes are especially used as wires of up-market cars,Production speed 20-30m/min.

|

Item

|

Name

|

Quanitty

|

|

1

|

Vacuum Feeder and Hopper Dryer

|

1 set

|

|

2

|

SJ-65/30 Single Screw Extruder (PLC control system)

|

1 set

|

|

3

|

Corrugated pipe die head

|

1 set

|

|

4

|

Core bar and mouth mould

|

1 set

|

|

5

|

pipe forming Mould(12-32mm)

|

1 set

|

|

6

|

Corrugated pipe forming machine

|

1 set

|

|

7

|

Double station Winding machine

|

1 set

|

|

8

|

Free spare parts

|

19 pcs

|

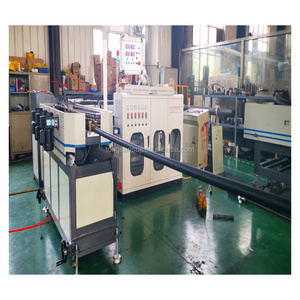

Machine detail

SJ 65/30 Single wall screw Extruder

High plasticification rate and stable production efficiency. High performance gearbox with longer using life and less noise.

PLC control system

All the parts using domestic and foreign well-known brands.ABB, OMRON, SIEMENS ,DELTA etc.

Screw/Barrel

FULLWIN designed single screw can satisfy pvc, pe, pp material production. The Surface Nitriding technology

significantly increase the Screw using life.

significantly increase the Screw using life.

High speed forming machine

1. Plate material hardness : 63.4HRC , more long life than 45# ;

2. Water cooling system;

3.

automatic and manual height adjustment

Mould material hardness : 63.4HRC , more long life than 45#

Mould

with two cavities

Mould

with engraving

New type heater

included 20mm rock wool to save energy 20% - 30%.

Core bar and mouth mould

FullWin new design,the core bar and mouth mould fit together,when change size,no lile the old design change the core bar and

mouthe separately,it will be save more than 1h for the clean the waste material.

mouthe separately,it will be save more than 1h for the clean the waste material.

Double station winder

Automatic wiring device which can balance the speed between pipe producing and rewinding.The device will stop rewinding when the pipe production is slow to prevent the pipe from getting too tight or disconnected.

Single wall corrugated pipe Product application

Shipping......

Our service

We provide Reliable Turnkey Project service

1, We will provide the Feasibility Analysis Report.

2, We will provide the model selection and technical parameter.

3, We will provide the design for the plant and electric power accounting for the facilities.

4, We will provide the design according to the product requirements.

5, We will provide technique training for operator.

6, We will provide solution for the practical problem during the production.

7, We will provide turnkey project to customers

1, We will provide the Feasibility Analysis Report.

2, We will provide the model selection and technical parameter.

3, We will provide the design for the plant and electric power accounting for the facilities.

4, We will provide the design according to the product requirements.

5, We will provide technique training for operator.

6, We will provide solution for the practical problem during the production.

7, We will provide turnkey project to customers

Our products

High speed Single-wall corrugated pipe extrusion line

Double wall corrugated pipe extrusion line

Corrugated pipe Auxiliary equipment

PVC/UPVC/CPVC Pipe extrusion line PVC/UPVC/CPVC

PE/PPR Compound pipe extrusion line PE/PPR

Spiral Corrugated pipe extrusion line

PVC Fiber-Reinforced pipe extrusion line PVC

PVC Suction Hose extrusion line PVC

PVC/WPC window frame profile/Door board extrusion line

PET/PP packing belt extrusion line

PP/PE/ABS plastic plate extrusion line

P VC Shinning/Semi-Shinning foam board extrusion line

PP Hollow Grid Sheet extrusion line

PP/PE Granulating extrusion line

EPE Fruit foam net extrusion machine

Auxiliary equipment

Double wall corrugated pipe extrusion line

Corrugated pipe Auxiliary equipment

PVC/UPVC/CPVC Pipe extrusion line PVC/UPVC/CPVC

PE/PPR Compound pipe extrusion line PE/PPR

Spiral Corrugated pipe extrusion line

PVC Fiber-Reinforced pipe extrusion line PVC

PVC Suction Hose extrusion line PVC

PVC/WPC window frame profile/Door board extrusion line

PET/PP packing belt extrusion line

PP/PE/ABS plastic plate extrusion line

P VC Shinning/Semi-Shinning foam board extrusion line

PP Hollow Grid Sheet extrusion line

PP/PE Granulating extrusion line

EPE Fruit foam net extrusion machine

Auxiliary equipment

Commissioning & Installation:

After all machines are delivered to customer's factory, buyer is responsible for all preparation work, e.g. electricity supply,

water supply, labors and cranes, etc.

- Fullwin will prepare for visa application for their engineers, who are responsible for guide of machine installation and testing at the Buyer's factory.

- The Buyer will buy the round-trip air ticket for Engineer if visa application is approved. The buyer is also responsible to bear expenses generated, e.g. visa formalities, meals, accommodation and allowance of 100 USD per day for each engineer.

- Engineer will give free training lessons to labors in buyer's factory.

- If buyer doesn't request installation and commissioning by Seller's engineer in 4 months since date of bill of lading, which to be accounted all the machines has been successfully tested by buyer.

water supply, labors and cranes, etc.

- Fullwin will prepare for visa application for their engineers, who are responsible for guide of machine installation and testing at the Buyer's factory.

- The Buyer will buy the round-trip air ticket for Engineer if visa application is approved. The buyer is also responsible to bear expenses generated, e.g. visa formalities, meals, accommodation and allowance of 100 USD per day for each engineer.

- Engineer will give free training lessons to labors in buyer's factory.

- If buyer doesn't request installation and commissioning by Seller's engineer in 4 months since date of bill of lading, which to be accounted all the machines has been successfully tested by buyer.

About Us

FULLWIN PLASTIC EXTRUSION MACHINE MANUFACTURER

Contact us

Hot Searches