- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Shiyue

-

Voltage:

-

220V,380V,440V,400V

-

Dimension(L*W*H):

-

8100*1650*3000mm

-

Marketing Type:

-

Brick making machinery 2022

-

Weight (KG):

-

5000 kg

-

Product Name:

-

Concrete Block Making Machine Brick

-

Pallet size:

-

900*700mm

-

Color:

-

Client Requirement

-

Vibration frequency:

-

4600 ( R/min)

-

Block Type:

-

hollow blocks, solid blocks, paver blocks, curbstone

-

Vibration type:

-

platform vibration

-

Molding cycle:

-

15-20s

-

Rated hydraulic pressure:

-

21Mpa

-

Mixer:

-

JS500/JS750 concrete mixer

-

After-sales Service Provide:

-

Online support, Free spare parts,Video technical support

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine

-

Brick Raw Material:

-

Cement

-

Production Capacity (Pieces/8 hours):

-

4480 pcs/8hours, 2500 pcs/8hours, 3400 pcs/8hours, 1920 pcs/8hours, 5760 pcs/8hours, 1500 pcs/8hours, 1280 pcs/8hours, 3000 pcs/8hours, 12000 pcs/8hours, 3200 pcs/8hours, 2560 pcs/8hours, 1000 pcs/8hours, 800 pcs/8hours, 1080-1440pcs/hour

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Shiyue

-

Voltage:

-

220V,380V,440V,400V

-

Dimension(L*W*H):

-

8100*1650*3000mm

-

Marketing Type:

-

Brick making machinery 2022

-

Weight (KG):

-

5000 kg

-

Product Name:

-

Concrete Block Making Machine Brick

-

Pallet size:

-

900*700mm

-

Color:

-

Client Requirement

-

Vibration frequency:

-

4600 ( R/min)

-

Block Type:

-

hollow blocks, solid blocks, paver blocks, curbstone

-

Vibration type:

-

platform vibration

-

Molding cycle:

-

15-20s

-

Rated hydraulic pressure:

-

21Mpa

-

Mixer:

-

JS500/JS750 concrete mixer

-

After-sales Service Provide:

-

Online support, Free spare parts,Video technical support

Products Description

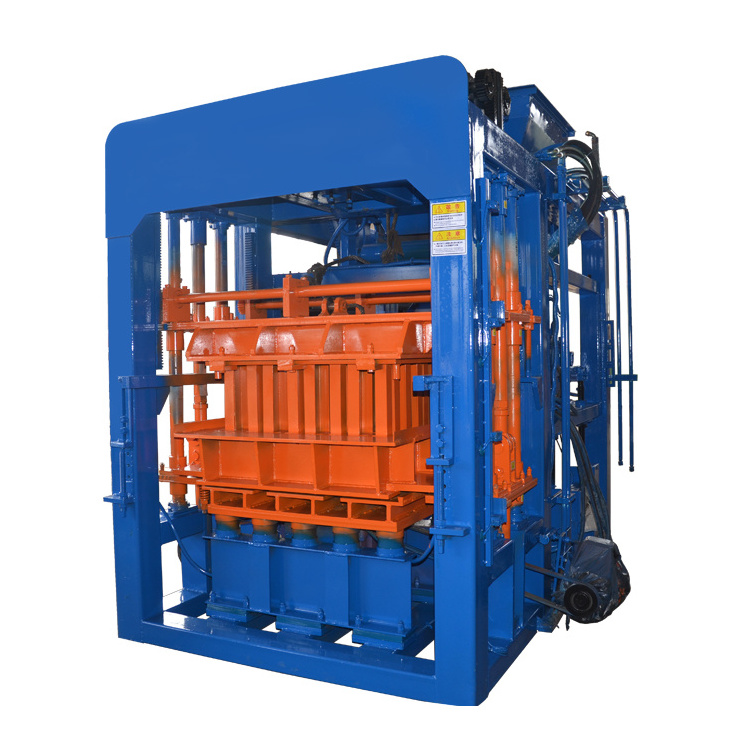

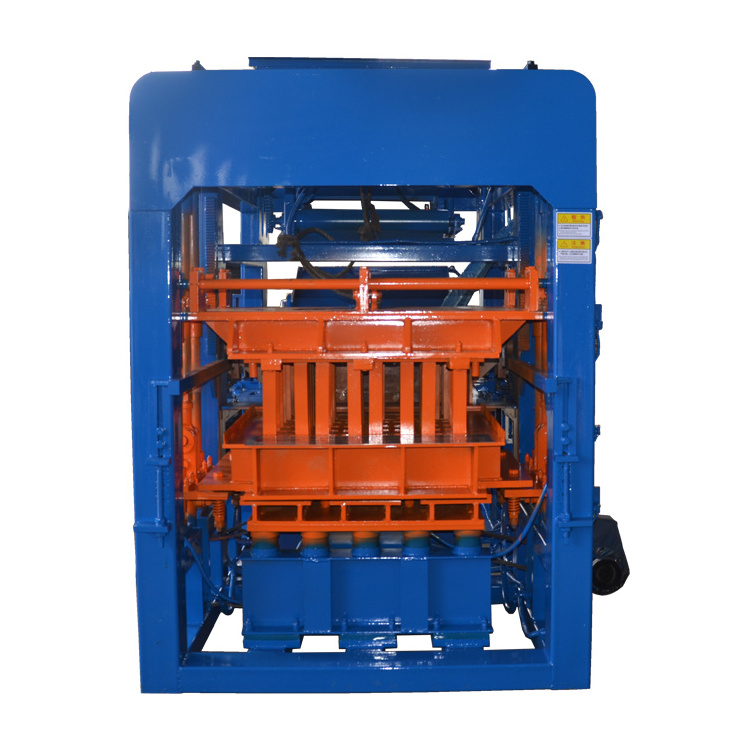

Introduction of QT6-15 automatic brick making machine concrete block making machine brick

2) The vibration system contains platform vibration and mould vibration, so the products is very close-grained and produced quickly.

3) Machine frame: Maganese steel with China national standard.

4) PLC intelligent control. Man-machine interface, control system equipped with complete logic control, production program,malfunction diagnosis system and remote control function.

5) The computer is of fault diagnosis system. Warning signal is propitious to eliminate the fault. Combine with long-distance controlling system, it can achieve scrutiny, controlling, diagnosis.

Parameter of QT6-15 automatic brick making machine concrete block making machine brick

|

Machine dimmenssion

|

7100*1500*3000mm

|

|

Total weight

|

6000KGS

|

|

Main Vibration

|

platform vibration

|

|

Vibration frequency

|

4500-5100r/min

|

|

Pallect size

|

850*680mm

|

|

Overall power

|

31.25KW

|

|

Vibration force

|

60KN

|

|

Molds

|

As customer’s requirement

|

|

Forming cycle

|

15-20s

|

|

Rated pressure

|

21MPA hydraulic pressure

|

|

Mixer

|

JS500 mixer

|

|

Machine Workplace

|

200-300m2

|

|

Voltage

|

220V/380V/415V as customer local voltage needs

|

|

Finished blocks

|

hollow blocks, paver,solid blocks, curbstone,porous blocks,stander bricks etc

|

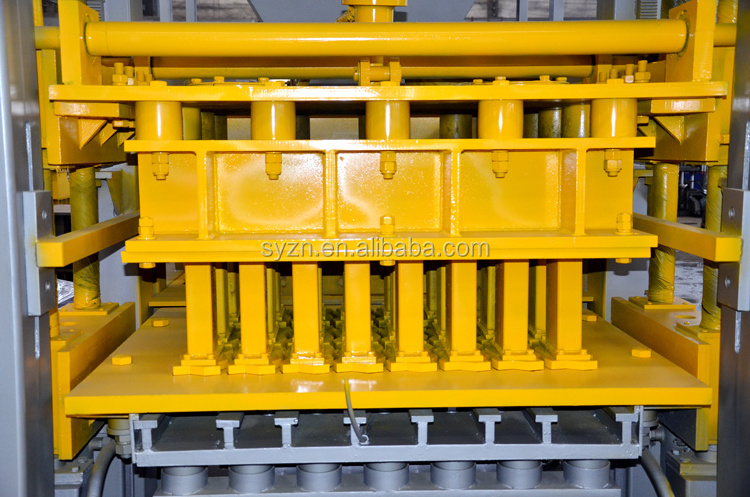

Block Machine Pictures

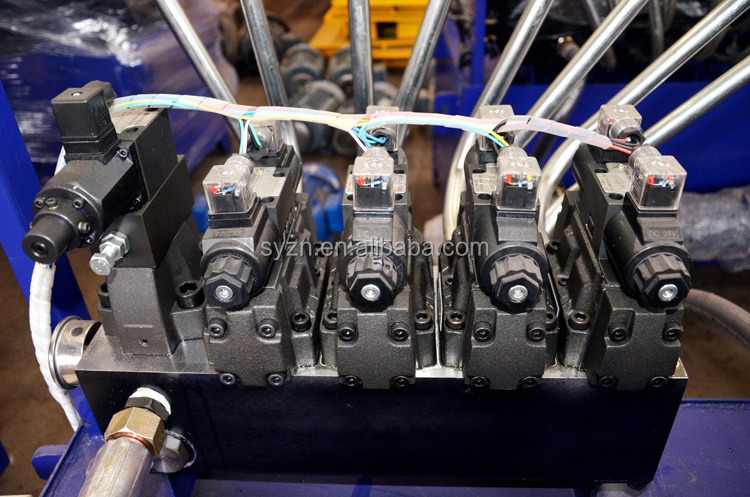

Hydraulic station

1.Guarantee the blocks with good quality, smooth appearance, high density 2.automatically adjust the oil flow and pressure

Carburized mould

1.improve the using lifetime of machine by 50%2.Hardness reached up to HRC 52

Siemens motor

1.Our vibration system adopt Siemens brand motors, vibration evently strong and quickly

2.It is more stable, can update the

production perimeters

production perimeters

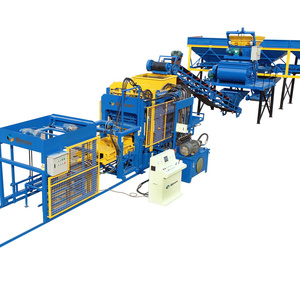

Optional equipment of QT6-15 automatic brick making machine concrete block making machine brick

1.According to your budget, efficiency and labor requirements, you can choose the configuration you need. The higher the degree of automation, the faster the efficiency.

2.You don't need take many times to find supplier to build a block machine factory, we will

provide integrated solution for block machine

3.No matter which project you perfer, actually you can reclaim your cost less than one year

provide integrated solution for block machine

3.No matter which project you perfer, actually you can reclaim your cost less than one year

Theoretical Blocks Capacity

|

Item

|

Block size(mm)

|

Pcs/ mould

|

Pcs/ mould

|

Pcs/ 8 Hours

|

|

Hollow block

|

400x200x200

|

6

|

1080-1440

|

8640-11520

|

|

Hollow block

|

400x150x200

|

8

|

1440-1920

|

11520-15360

|

|

Standard brick

|

240*115*53

|

30

|

5400-7200

|

43200-67500

|

You can use one machine produce different type blocks just changing moulds

It can produce hollow/solid blocks, riverside bricks, revetment bricks, square bricks, grassed bricks ,paver, interlocking blocks,curbstone,colored paver ,etc with different moulds. If you have special shape,our engineer also can special design mould for you.

Packaging And Shipping

Packing is nude package or plastic according to customer need

1. The whole

QT6-15 automatic brick making machine concrete block making machine brick

production line equipment is mainly the full container sea shipping,

2. Brick machine equipment finish manufacturing and testing, next to clean up, and then do another paint protection,

3. Before shipment to use plastic film winding, wrapped the entire brick machine in case of water or moisture,

4. Then load brick machines into the container by forklift,

5. During loading to tighten the machine with reinforcement ring in container, so as to avoid the damage by transport bumps on the brick machine.

2. Brick machine equipment finish manufacturing and testing, next to clean up, and then do another paint protection,

3. Before shipment to use plastic film winding, wrapped the entire brick machine in case of water or moisture,

4. Then load brick machines into the container by forklift,

5. During loading to tighten the machine with reinforcement ring in container, so as to avoid the damage by transport bumps on the brick machine.

Our Service

Pre-sale Service of QT6-15 automatic brick making machine concrete block making machine brick

(1) Professional suggestions (raw material matching, machine selection, plan

The condition of build factory, feasibility analysis for brick machine production line)

(2) Device model choice (recommend the best machine according to the raw material,

capacity and the size of brick)

(3) Visit our factory

The condition of build factory, feasibility analysis for brick machine production line)

(2) Device model choice (recommend the best machine according to the raw material,

capacity and the size of brick)

(3) Visit our factory

After-sale Service of QT6-15 automatic brick making machine concrete block making machine brick

(1) The engineer will guide to carry out the plant at the clients side.

(2) Set up, fix,and operate

(3) 24 hours service

(2) Set up, fix,and operate

(3) 24 hours service

Customer feedback of QT6-15 automatic brick making machine concrete block making machine brick

We has cooperated with more than 50 countries and received high reputation from our customer.We have won a good reputation among customers with good quality, competitive prices and advanced techniques since our establishment.

Hot Searches