37kw Siemens motor

Double alloy screw material

Melt pressure display

PLC temperature control, 15-inch touch screen

- Product Details

- {{item.text}}

Quick Details

-

Heating Power (kW):

-

22 kW

-

Production Speed(times/h):

-

45

-

Power Supply:

-

Three-phase

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ACEMIEN

-

Voltage:

-

Three-phase

-

Dimension(L*W*H):

-

7000mm*1400mm*2000mm

-

Weight (T):

-

6 T

-

Name:

-

Extrusion Line

-

Raw material:

-

pet pp pla Powder

-

Usage:

-

Plastic Forming Machine

-

Inverter:

-

ABB Brand

-

Motor:

-

SIEMENS Brand

-

Contactor:

-

Schneider Brand

-

Temperature control:

-

Omron Brand

-

Marketing Type:

-

Hot Product 2023

Quick Details

-

Max.Forming Height(mm):

-

80 mm

-

Forming Width (mm):

-

850 mm

-

Forming Length (mm):

-

350 mm

-

Heating Power (kW):

-

22 kW

-

Production Speed(times/h):

-

45

-

Power Supply:

-

Three-phase

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ACEMIEN

-

Voltage:

-

Three-phase

-

Dimension(L*W*H):

-

7000mm*1400mm*2000mm

-

Weight (T):

-

6 T

-

Name:

-

Extrusion Line

-

Raw material:

-

pet pp pla Powder

-

Usage:

-

Plastic Forming Machine

-

Inverter:

-

ABB Brand

-

Motor:

-

SIEMENS Brand

-

Contactor:

-

Schneider Brand

-

Temperature control:

-

Omron Brand

-

Marketing Type:

-

Hot Product 2023

Products Description

Single Screw Extruder

Customized Mold

1. Maximum mold install area reaches 850mm*350mm.

2. All mold are customized, client choose to add logo, words and signs on mold.

3.Each Line comes with one set of free customized mold.

3.Each Line comes with one set of free customized mold.

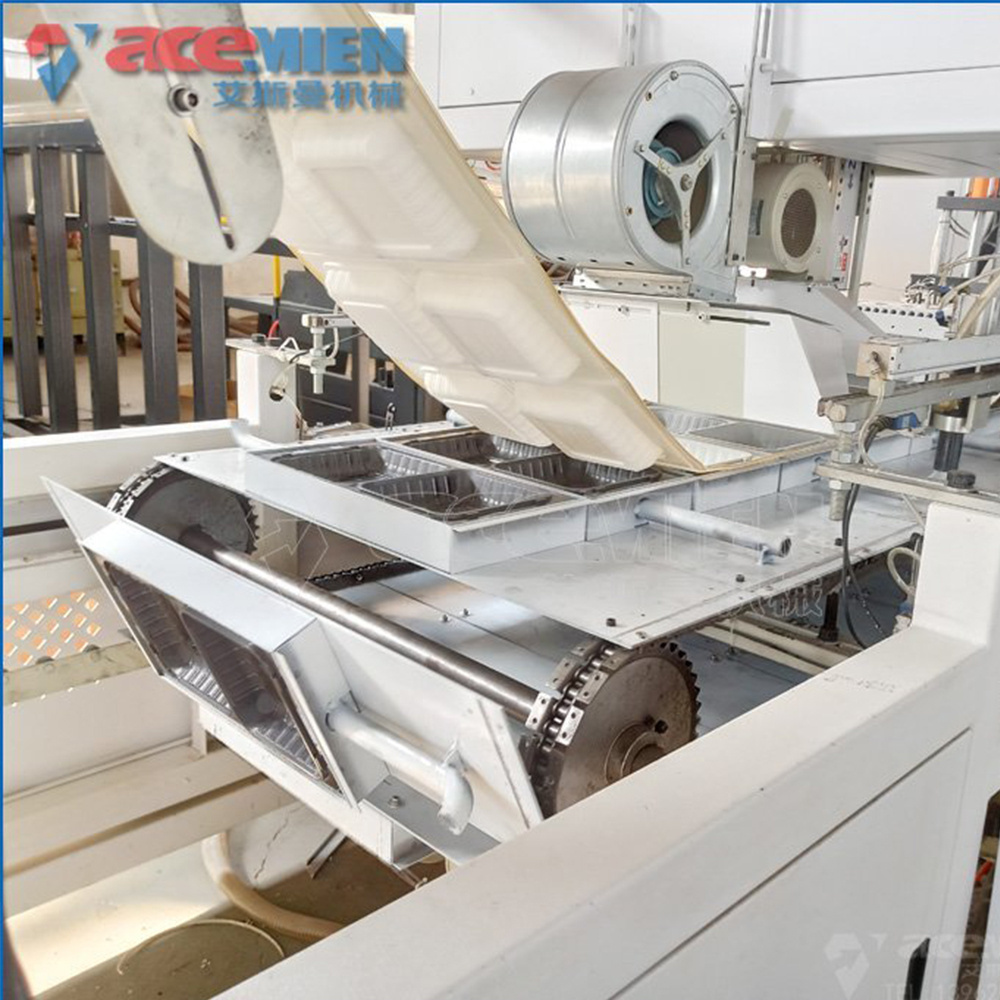

High Speed Forming

Setting time: 0.2 seconds

Maximum forming area: 850mm*300mm

Maximum forming speed: 80mm-120mm

Production speed: 45-60 molds/min

Maximum forming area: 850mm*300mm

Maximum forming speed: 80mm-120mm

Production speed: 45-60 molds/min

Automatic Hydraultc Press

Stamping method: pneumatic forward/recoil type

Feature of equipment

1) Use programmable logic controller (PLC) to realize automatic control and digital operation.

2) The automatic lifting and feeding system is safe and labor-saving. The temperature control system of the plate-type upper and lower preheating device is stable to ensure uniform heating. The punching and punching knives are durable and free of burrs. The high pressure cutting laser knife has low cost and good effect. The mold replacement is simple. The host adopts frequency conversion adjustment. Speed running smoothly.

3) The whole is welded with steel box body, the structure is firm and does not deform, the bracket and box body are formed by pressure, with high density, no air holes, and the appearance is uniformly wrapped in stainless steel, which is beautiful and generous. Easy to maintain.

4) The roller servo traction system makes the machine run more stable and reliable, and

increases the traction length. The traction length and traction speed can be set through PLC, which increases the forming area and expands the scope of application.

5) The plane linkage mechanism is adopted, the transmission force is larger, the inertia effect is smaller, the operation is stable, and the pressing and cutting force is larger.

Our Advantages

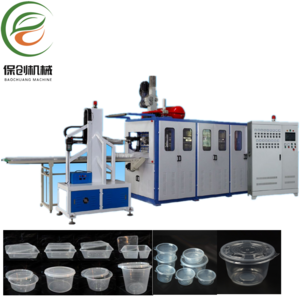

1. The fully automatic one-step blister machine refers to the use of raw material pellets (including leftover materials, fillers,etc.) directly into the equipment for production. The unit includes three parts: extrusion, molding, and punching. One-stop production.

2. There is no need to buy sheets, no secondary heating, and scraps can be recycled without waste. If automatic feeding equipment is added, one machine and one packer can be used. The product cost is basically the material cost + processing fee. The processing

fee includes the electricity fee, rent, etc. for the artificial carton. The cost and price of each ton of product are different depending on the size of the product.

3. The operation is simple. After on-site installation and debugging training, it can basically operate independently.

4. The equipment has wide adaptability, adapts to various materials, and the cost of upgrading or modification is relatively low.

2. There is no need to buy sheets, no secondary heating, and scraps can be recycled without waste. If automatic feeding equipment is added, one machine and one packer can be used. The product cost is basically the material cost + processing fee. The processing

fee includes the electricity fee, rent, etc. for the artificial carton. The cost and price of each ton of product are different depending on the size of the product.

3. The operation is simple. After on-site installation and debugging training, it can basically operate independently.

4. The equipment has wide adaptability, adapts to various materials, and the cost of upgrading or modification is relatively low.

Machine List

|

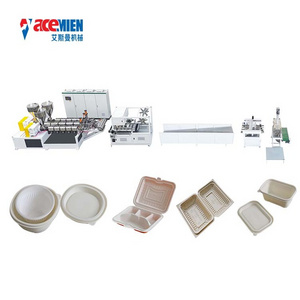

Single/Two/Four layer Biodegradable Meal Box Production Line

|

|

|

||

|

No

|

Machine List

|

Qty

|

||

|

1

|

Vacuum Feeder

|

1set

|

||

|

2

|

Dryer

|

1set

|

||

|

3

|

SJ90(Single)/SJ75(Two layer)/SJ65(Four) Single Screw Extruder

|

1set

|

||

|

4

|

Hydraulic Screen Changer

|

1set

|

||

|

5

|

Extrusion Mould

|

1set

|

||

|

6

|

High Speed Forming Machine

|

1set

|

||

|

7

|

Automatic Conveyor

|

1set

|

||

|

8

|

Automatic Hydraulic Press

|

1set

|

||

product application

Hot Searches