- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Workshop

-

Design Style:

-

Traditional

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

Zhongcai

-

Model Number:

-

G-16

-

Product Code:

-

AS-20

-

Max.Service Temperature:

-

1600℃

-

Bulk Density g/cm3:

-

110℃ X24h≥2.6

-

Thermal Shock Resist(Water Cool Times):

-

1100℃ ≥20

-

Abrasion Resistance:

-

1100℃X3h≤4.0

-

Modulus of Rupture at Elevated Temp:

-

1200℃X0.5h≥10

-

Certificate:

-

ISO9001, CE

-

Sample:

-

Avaliable

-

Main Use:

-

Kiln Outlet

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Online technical support, Onsite Installation, Onsite Training, Onsite Inspection

-

Project Solution Capability:

-

graphic design

-

Application:

-

Workshop

-

Design Style:

-

Traditional

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

Zhongcai

-

Model Number:

-

G-16

-

Product Code:

-

AS-20

-

Max.Service Temperature:

-

1600℃

-

Bulk Density g/cm3:

-

110℃ X24h≥2.6

-

Thermal Shock Resist(Water Cool Times):

-

1100℃ ≥20

-

Abrasion Resistance:

-

1100℃X3h≤4.0

-

Modulus of Rupture at Elevated Temp:

-

1200℃X0.5h≥10

-

Certificate:

-

ISO9001, CE

-

Sample:

-

Avaliable

-

Main Use:

-

Kiln Outlet

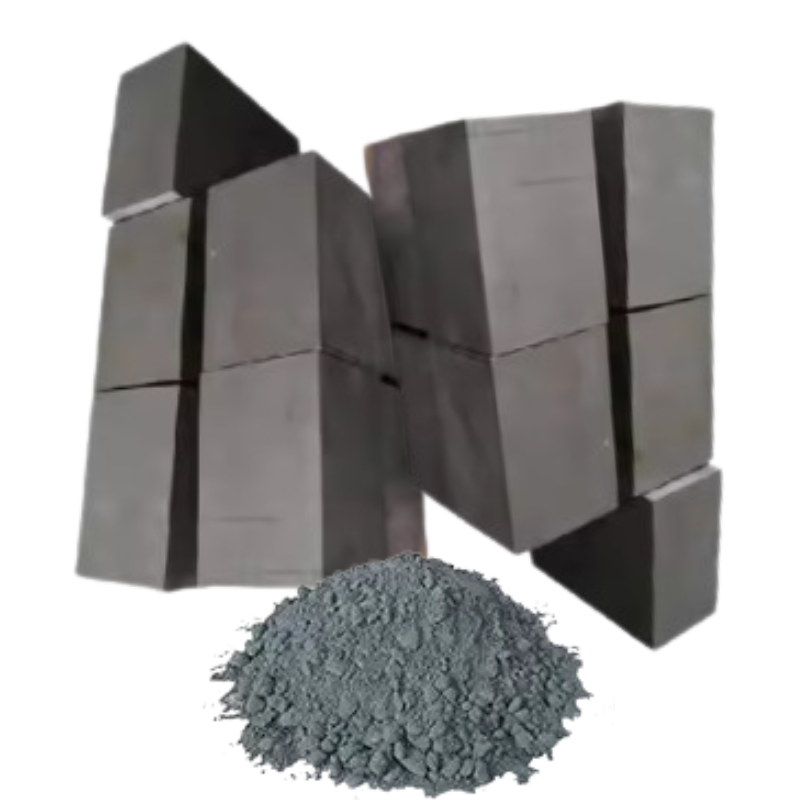

Our Refractory Castable is made with top-quality materials and cutting-edge technology. This specialized mix of aggregates,

binders, and additives withstands extreme temperatures and tough conditions. Our advanced production ensures reliable,

consistent quality for effective refractory solutions.

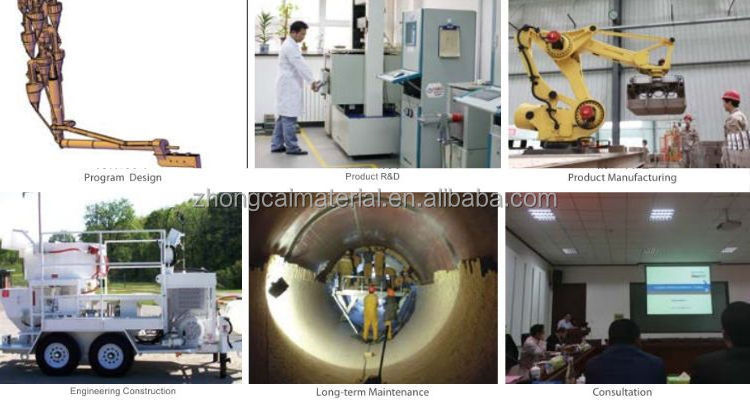

We provide comprehensive and personalized refractory design and diagnosis services for burner pipe, which includes the analysis of

refractory damage mechanism as well as operating environment,installation technology temperature field, stress field numericalsimulation.

Detailed installation drawings, product design andinstallation program are also provided.

Our Castalble product lineup includes a comOprehensive range of both shaped and unshaped refractory products.

This includes insulating and dense castables, high alumina series bricks, corundum series bricks, silica series bricks,

mullite bricks, andalusite bricks, magnesia series bricks, carborundum bricks, and insulating series bricks.

Our product range includes a broad selection of refractory materials, both shaped and unshaped. We offer insulating and dense castables, insulating series bricks,

and high alumina, silica, corundum, mullite, andalusite, magnesia, and carborundum series bricks.

Refractory Castables Classification:

- Chemical Properties: Divided into acid-resistant, neutral, and alkali-resistant castables.

- Density: Categorized into lightweight and heavyweight castables.

- Material Composition: Includes clay, high alumina, siliceous, mullite, corundum, magnesia, and silicon carbide castables.

- Performance Characteristics: Varieties include high-strength wear-resistant, high-temperature wear-resistant, low-cement, steel fiber-reinforced, acid-resistant, heat-resistant, slag-resistant, and other specialized castables.

- Application Areas: Suitable for various industrial furnaces such as steel rolling heating furnaces, blast furnace runners, metal mixers, ladles, boilers, furnace doors, cement kilns, etc.

Selecting the correct type of refractory castable is essential, as the requirements vary significantly across different industrial furnace environments.

| Technical Data | ||

| Product Code | AS-20 | |

| Max.Service Temperature | 1600℃ | |

| Chemical Composition(%) | AI203+SiC | ≥75 |

| Bulk Density(g cm) | 110℃X24h | ≥2.6 |

| Modulus of Rupture(MPa) |

110'C X 24h |

≥7 |

| 1100℃X3h | ≥8 | |

| 1400℃X3h | ≥8 | |

| Coid Crushing Strength(MPa) | 110'C X24h | ≥60 |

| 1100'C X3h | ≥80 | |

| 1400"C X3h |

≥80.

|

|

| Permanent Linear Change(%) | 1100C X3h | +-0.2 |

| 1400℃X3h | +-0.4 | |

| Modulus of Rupture at Elevated Temperatures | 1200℃X0.5h | ≥10 |

| Abrasion Resistance(cc) | 1100℃X3h | ≤ 4.0 |

| Thermal Shock Resistance(Water Cooling,Times) | 1100℃X3h | ≥20 |

| Main Use | Kiln Outlet | |