- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customized

-

Power:

-

125.74KW

-

Weight:

-

60 About Tons

-

Dimension(L*W*H):

-

10*10*10 Meters About

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Japan, Malaysia, Australia, Morocco, Kenya, Argentina, South Korea, Chile, Colombia, Algeria, Sri Lanka, Bangladesh, South Africa, Kazakhstan, Nigeria, Uzbekistan, Tajikistan

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Product Name:

-

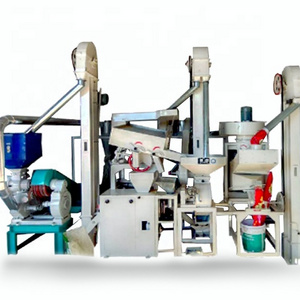

Best Quality Fully Automatic Parboiled Rice Mill Plant

-

Holding Bins:

-

25 Tons per Set, 2 Sets in Total

-

Elevataors and Auto Gates:

-

Provided

-

Conveyor and Boiler:

-

Provided

-

25 Tons Soaking Tank:

-

4 Sets

-

50 Tons Tower Dryers:

-

2 Sets

-

Blower and Husk Furnace:

-

Provided

-

Cyclone, Tubes, Cables, Wires:

-

Provided

-

Electrical Control Cabinet:

-

Provided

-

Rice Mill Parts:

-

Provided

-

Certification:

-

ISO, CE

Quick Details

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

ANON

-

Production Capacity:

-

100 Tons Per Day

-

Voltage:

-

Customized

-

Power:

-

125.74KW

-

Weight:

-

60 About Tons

-

Dimension(L*W*H):

-

10*10*10 Meters About

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Japan, Malaysia, Australia, Morocco, Kenya, Argentina, South Korea, Chile, Colombia, Algeria, Sri Lanka, Bangladesh, South Africa, Kazakhstan, Nigeria, Uzbekistan, Tajikistan

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Product Name:

-

Best Quality Fully Automatic Parboiled Rice Mill Plant

-

Holding Bins:

-

25 Tons per Set, 2 Sets in Total

-

Elevataors and Auto Gates:

-

Provided

-

Conveyor and Boiler:

-

Provided

-

25 Tons Soaking Tank:

-

4 Sets

-

50 Tons Tower Dryers:

-

2 Sets

-

Blower and Husk Furnace:

-

Provided

-

Cyclone, Tubes, Cables, Wires:

-

Provided

-

Electrical Control Cabinet:

-

Provided

-

Rice Mill Parts:

-

Provided

-

Certification:

-

ISO, CE

ANON automatic parboiled rice mill machine and rice mill in nepal

1. This parboiled rice mill machinery can not only apply for parboiled rice mill, but also rice mill.

2.The device is based on rice (paddy) as raw material, after hydro-thermal treatment, such as cleaning, soaking, cooking, drying, etc.Then according to the conventional rice milling processing method to process rice products, with high value of nutrition, good quality, highly output rate, high oil recovery, long storage life, and short cooking time, etc.

3. Parboiled rice processing technology Paddy rice----cleaning---soaking---steaming---drying and cooling---husking---milling---grading and polishing---color sorting---packing

1) Cleaning firstly, the paddy need to be cleaned in this stage. It should remove the dust and impurity. Through the screen, the paddy will be cleaner when remove the straw and leaf, and other impurity, such as stone and so on.

2) Soaking paddy.

A. This stage is aimed to make the paddy absorb enough moisture, which need to be above 30%. And it will create a good condition for the starch dextrinization.

B. According to the rice type and quality, usually the soaking temperature is 55-70 degrees, and soaking time is 3.5-4.5 hours.

3) Steaming and boiling. The water vapor with a certain temperature and pressure heated to the paddy, so that starch dextrinization. This operation has a great influence to the parboiled rice finished product quality, color and taste, it can increase the strength of the grain, increase the rate of rice, and change the rice storage characteristics. By adjusting the cooking process conditions, can produce color for the light, sub-dark, and dark steamed rice.

4) Drying and Cooling This is aimed to reduce the moisture to increase production ratio and easy to store and transport.

| Anon 20TPD Parboiled Rice Mill Production Line | ||

| Description | Capacity | Power |

| Bucket Elevator | 5-10TPH | 1.5KW |

| Conveyor | 10TPH | 4KW |

| Tower Paddy Dryer | 10 Tons Per Batch | 4.7KW |

| Blower | 2.2KW | |

| Husk Furnace | 8.01KW | |

| Holding Bins | 4 Tons | |

| Auto Gate | 10 Tons | 0.37 |

| Soaking Tons | 4 Tons | |

For more information, please contact with us by mail directly!