- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.7-1.2mm

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

TACON

-

Weight:

-

3500 kg

-

Feeding width:

-

575/600/610mm

-

Marketing Type:

-

Hot Product

Quick Details

-

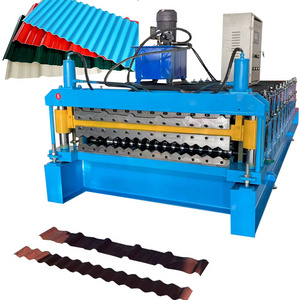

Type:

-

Tile Forming Machine

-

Tile Type:

-

Glazed Steel

-

Production Capacity:

-

20 m/min

-

Rolling thinckness:

-

0.7-1.2mm

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

TACON

-

Weight:

-

3500 kg

-

Feeding width:

-

575/600/610mm

-

Marketing Type:

-

Hot Product

Product Overview

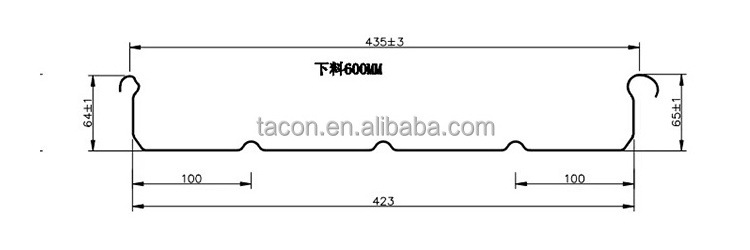

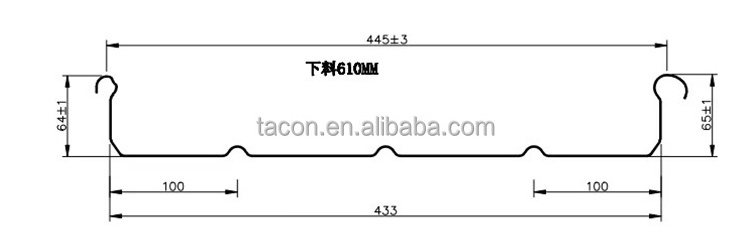

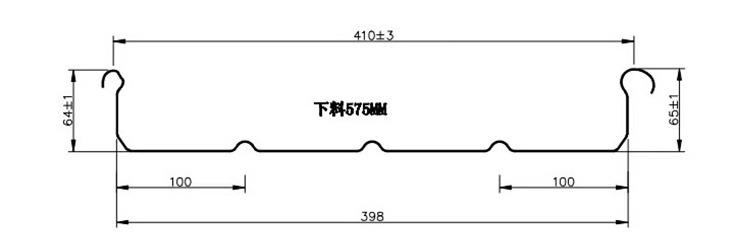

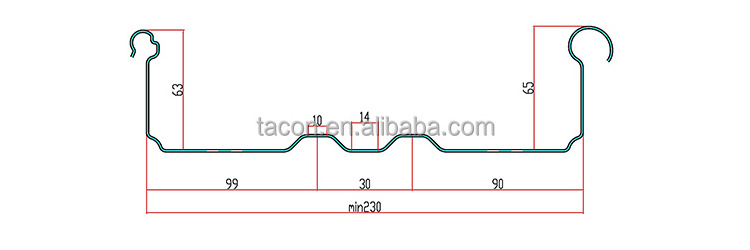

Profile Drawing

(three sizes)

Our machines can be customized according to your requirements.

Double-Side Taper Profile: Min.230mm

Material

1.Aluminum coil: 0.7-1.2mm, 2.Yield strength: 250Mpa 3.Pre-painted coil: 0.6-0.8mm,

4. Yield strength: 550Mpa 5.0.6mm pre-painted coil is for inspection, in common use

6.Feeding width: approx.575/600/610mm 7.Effective width: 410/435/445mm

6.Feeding width: approx.575/600/610mm 7.Effective width: 410/435/445mm

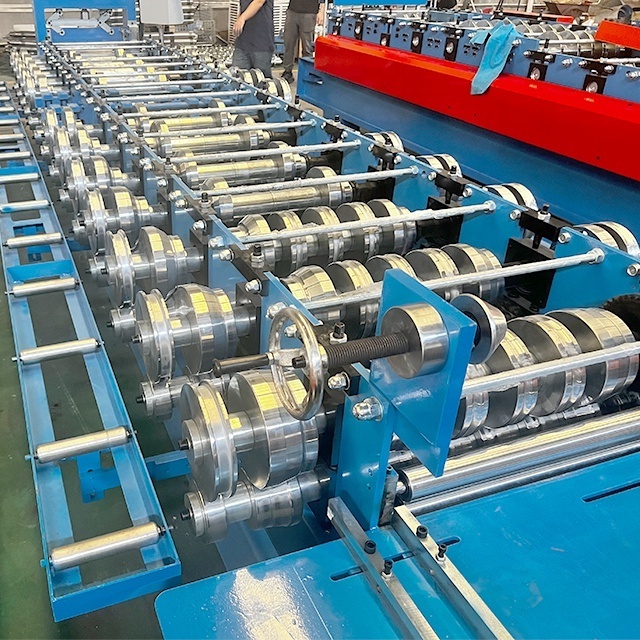

Machine Components

|

No

|

Item

|

QUANTITY

|

|

1

|

Manual decoiler

|

1SET

|

|

2

|

Guide with adjustable

|

1SET

|

|

3

|

Roll forming machine

|

1SET

|

|

4

|

Hydraulic cutting

|

1SET

|

|

5

|

Product support table

|

1SET

|

|

6

|

Plc Control System

|

1SET

|

Work Flow

Decoiler→Guide with Adjustable →Roll forming machine → Hydraulic cutting → Product Support Table

PRODUCT SPECIFICATIONS

|

NO.

|

ITEM

|

MAIN TECHNICAL SPECIFICATIONS

|

|

1

|

Decoiler

|

type of Driver: Manual

|

|

|

|

Diameter of Outer:1500mm

|

|

|

|

Inner Diameter: 508+/30mm

|

|

|

|

Capacity Weight: 5T

|

|

2

|

Roll forming Machine

|

Filming-On device for protecting film, Un-Powered

|

|

|

|

Including two parts of roll former, One for middle roll former for straight profile, cut-to-length control Another for side roll former for taper profile, feed in piece by piece by manual,The both parts in the same stage share in one shaft.

|

|

|

|

Shafts Diameter=ф75mm, Precision Machined, fine Polished

|

|

|

|

Gear/Sprocket driving;13 stages to form

|

|

|

|

Rollers manufactured from 45#, CNC lathes, hard Chrome Coated

|

|

|

|

Main motor :2*5.5KW=11 KW, Frequency speed control

|

|

|

|

Max. liner speed of roll former:Approx. 20 m/min

|

|

3

|

Hydraulic Cutting

|

Stop to Cut, Post Cut, Slug Breaker

|

|

|

|

Material of cutting tool: Cr12, Heat treatment

|

|

|

|

Three sets of cutting blades

|

|

|

|

Pump motor = 2.2 KW

|

|

4

|

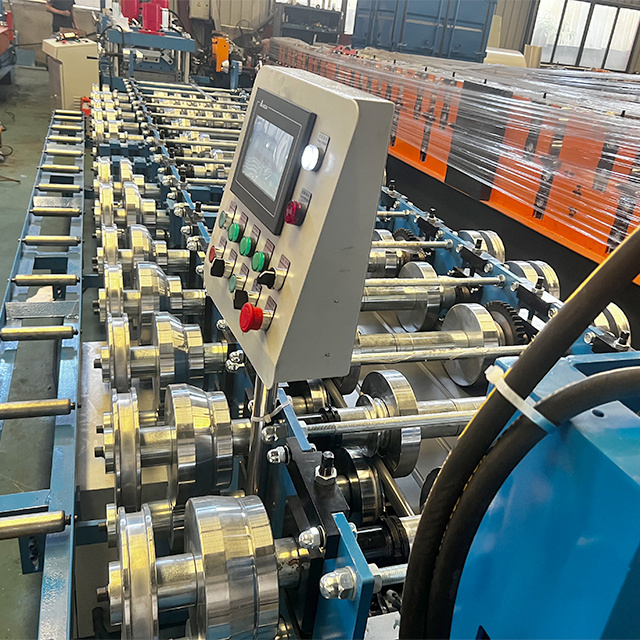

PLC Control System

|

Control the quantity & cutting length automatically.

|

|

|

|

Combined with: PLC, Touch Screen (Delta), Inverter (Delta), Encoder (Omron),etc

|

|

|

|

Cut-to-length tolerance≤±2.0 mm

|

|

|

|

Control voltage 24V

|

|

5

|

Product Rack

|

Un-powered, 5 units

|

SALES AND SERVICE NETWORK

Successful Project

SIMILAR PRODUCTS

FAQ

A: Can you customize the machine from your company?

- Of course, we can manufacture the machine according to your customized size demand.

B: What service can you provide before order?

- About the pre-sale service. We provide you answers of all your questions on our machines, such as technical parameter,

price,payment terms, ect. If you wanna visit our factory and check the machines, we also can send you invitation letter and give you our warmest welcome.

C: How is the quality? Is there any department related to quality control?

-All raw materials we use are quality controlled. Workers will take care of every detail when handling production and

packaging.The quality control department is responsible for the quality of each process.

D:Can you finish the machine during the delivery time?

--We will finish the machine in time according to determined lead time.

E:How about after-sales service?

-The warranty is one year. and we will provide the technical support for the whole life. It is free to maintain the machine the

first year after buying, including changing the main components. The first year hence,We can send technician to your country to fix the machine. The buyer should bear all the cost including: visa, Roundtrip ticket and suitable accommodation, also buyer should pay the salary 80USD/day.

B: What service can you provide before order?

- About the pre-sale service. We provide you answers of all your questions on our machines, such as technical parameter,

price,payment terms, ect. If you wanna visit our factory and check the machines, we also can send you invitation letter and give you our warmest welcome.

C: How is the quality? Is there any department related to quality control?

-All raw materials we use are quality controlled. Workers will take care of every detail when handling production and

packaging.The quality control department is responsible for the quality of each process.

D:Can you finish the machine during the delivery time?

--We will finish the machine in time according to determined lead time.

E:How about after-sales service?

-The warranty is one year. and we will provide the technical support for the whole life. It is free to maintain the machine the

first year after buying, including changing the main components. The first year hence,We can send technician to your country to fix the machine. The buyer should bear all the cost including: visa, Roundtrip ticket and suitable accommodation, also buyer should pay the salary 80USD/day.

Hot Searches