- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

Hot Product 2024

-

Core Components:

-

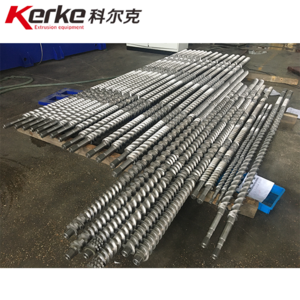

screw

-

Material:

-

38CrMoAL/Alloy

-

Screw diameter:

-

10mm-300mm

-

Application:

-

Construction industry machinery

-

Product name:

-

Extruder barrel screw

-

Surface treatment:

-

Nitride

-

Core selling points:

-

High precision

-

Applications:

-

Workshop

-

Size:

-

processing with supplied drawings

-

Color:

-

optional

-

characteristic:

-

Strong wear resistance

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

cj

-

Weight (KG):

-

85

-

Marketing Type:

-

Hot Product 2024

-

Core Components:

-

screw

-

Material:

-

38CrMoAL/Alloy

-

Screw diameter:

-

10mm-300mm

-

Application:

-

Construction industry machinery

-

Product name:

-

Extruder barrel screw

-

Surface treatment:

-

Nitride

-

Core selling points:

-

High precision

-

Applications:

-

Workshop

-

Size:

-

processing with supplied drawings

-

Color:

-

optional

-

characteristic:

-

Strong wear resistance

Products Description

Extruder screw

The screw section of the film blowing machine has a fixed groove depth for the screw groove. In addition to its main functions of mixing, melt output and delivery, and metering, it must also provide sufficient pressure to maintain a uniform temperature of the melt and stabilize the flow of the molten plastic. Metering section If the metering section is long, the mixing effect will be better; if the metering section is too long, the melt will easily stay for too long and cause thermal decomposition; if it is too short, the temperature will be uneven.

Details Images

Mixing head

1. Mixed materials

2. Disperse filling materials

3. Uniform feeding

4. Realize fast residence time and fully melt

Circular alloy sleeve

Stable and fast feeding, providing better mixing effect

Alloy barrel

The alloy barrel is a layer of 2-4mm wear-resistant, corrosion-resistant, and high-temperature-resistant alloy centrifugally cast on the inner wall of the barrel. Its effective service life is greatly improved than that of ordinary nitrided barrels. For processing PA66, glass brazing is required for more than 30%. Formulas such as PVC with high calcium powder can increase the wear life, and the advantages of bimetal are particularly obvious.

Product Paramenters

|

Country of origin

|

|

Zhejiang, China

|

|

|

|||

|

State

|

|

New

|

|

|

|||

|

Material

|

|

Full hard iron-based powder metallurgy

|

|

|

|||

|

Quenching and tempering hardness

|

|

HB260-290

|

|

|

|||

|

Nitride hardness

|

|

Nitride hardness

|

|

|

|||

|

Nitride layer depth

|

|

0.4-0.7mm

|

|

|

|||

|

Nitride embrittlement

|

|

≤ Level 1

|

|

|

|||

|

Surface roughness

|

|

Ra0.4

|

|

|

|||

|

Alloy layer thickness

|

|

1.5~2.0mm

|

|

|

|||

|

Screw straightness

|

|

0.015mm

|

|

|

|||

|

Chromium plating thickness

|

|

0.05-0.10mm

|

|

|

|||

|

Dual alloy hardness

|

|

HRC56-65

|

|

|

|||

|

Double alloy depth

|

|

0.8-2.0mm

|

|

|

|||

Hot Searches