- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±1%

-

Voltage:

-

Customized

-

Place of Origin:

-

Jiangsu

-

Brand Name:

-

BOTTLING

-

Dimension(L*W*H):

-

1500*800*1800mm

-

Weight:

-

400 KG

-

Product name:

-

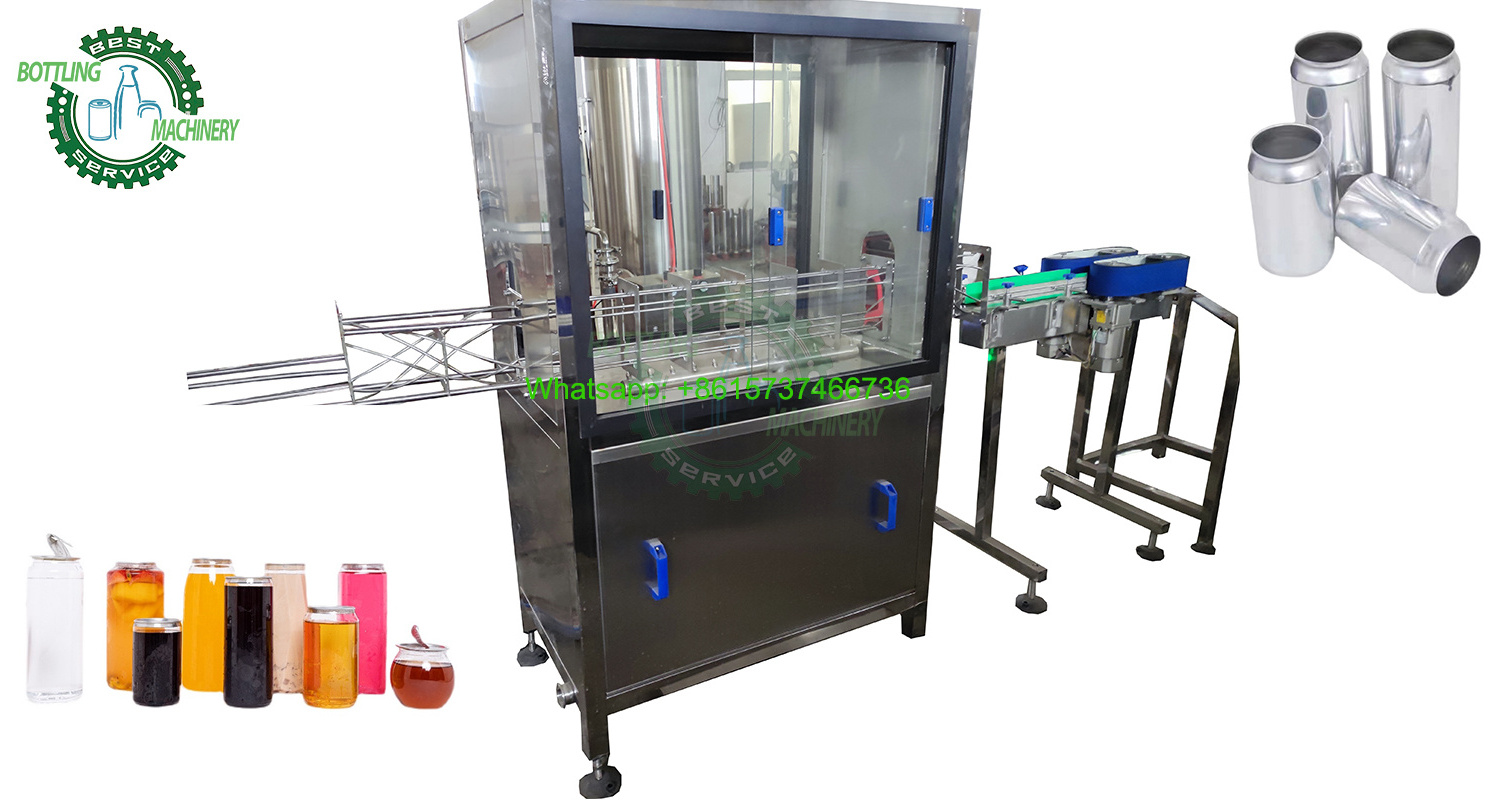

Can air rinsing machine

-

Washing speed:

-

1500-3000CPH

-

Automatic level:

-

Automatic

-

Can volume:

-

100-750ml

-

Material:

-

SUS304

-

Package:

-

Wooden Package

-

Control type:

-

PLC, Motor

-

Advantage:

-

With can turning device

-

Certificate:

-

CE/ISO9001

Quick Details

-

Machinery Capacity:

-

2000BPH

-

Packaging Material:

-

Plastic, Glass, Aluminum

-

Filling Material:

-

Water

-

Filling Accuracy:

-

±1%

-

Voltage:

-

Customized

-

Place of Origin:

-

Jiangsu

-

Brand Name:

-

BOTTLING

-

Dimension(L*W*H):

-

1500*800*1800mm

-

Weight:

-

400 KG

-

Product name:

-

Can air rinsing machine

-

Washing speed:

-

1500-3000CPH

-

Automatic level:

-

Automatic

-

Can volume:

-

100-750ml

-

Material:

-

SUS304

-

Package:

-

Wooden Package

-

Control type:

-

PLC, Motor

-

Advantage:

-

With can turning device

-

Certificate:

-

CE/ISO9001

Products Description

Can washing machine(air rinsing + water rinsing)

We can many models of can washing machine.

Like The

Horizontal can washer and the can washer connected to

depalletizer.

Like the air rinsing can washing machine and water rinsing can washing machine.

Please let me know what your product and the filling speed, then we will recommend you the suitable model.

Ionized air can washing machine

The manufacturers of cans, bottles and jars usually perform a liquid cleaning/sanitizing process prior to shipping their finished empty containers to the food and beverage plants who will then fill them. As a quality control process, the food and beverage companies have in the past sent inverted containers through a water rinsing step after de-palletizing the to ensure no foreign material (dust, cardboard, etc.) has inadvertently entered the containers before the filling machines. Some of the higher speed filling lines, and others concerned about introducing water to their product, began using air rinsing with ionized compressed air nozzles as an acceptable alternative to water rinsing. Today the high operating cost of compressed air has made blower powered air rinsing the new standard.

Can water washing machine

connected with can feeding table/conveyor

This can washer is horizontal revolution type can washer;

One end of the cabinet is entrance of the cans, usually it do not need to work together with unpiler.

After the cans loading, they will be reversed 90 degree and pass the cabinet with motor transsimmision pushing when can mouth face to ground. The cabinet is inside set with 12 pcs of shower to spray water inside the cans to wash. After washing, the cans will be reversed again 90 degree to loaded on conveyor connected to filler.

The cabinet is connected with pump for water discharge. And the cabinet is with checking winder to check if any problem happen inside and water collection tray.

Parameters:

Power: 0.75KW

Dimension: 1500* 800*1800mm

Can water washing machine connected with

depalletizer

The equipment of the former cans twist cage and the depalletizer of the rapid transport connection, from the empty cans down through the turn of the tank can be turned 90 °, into the tank down into the empty tank cleaner cleaning tank, tank installed at the bottom Spray pipes, and 12 nozzles into the empty cans sprayed with water, spray length of about 850mm. Water tank after the paragraph for the drain section, sprayed into the empty tank of the cleaning water automatically into the water tank, by the back of the drainage pipe for waste water discharge. The cleaned empty cans are turned 90 ° from the back of the cans, into the cans upward into the conveyor belt into the tank.

The cans were mainly composed of the imported cans, the spray water tank and the straight transportation chute, the sprinkling pipe and the outlet pipe, the outlet canning device, the installation base and so on.

The canister and the linear conveying chute are made of Φ5 ~ Φ6mm stainless steel rods. The spray water tank is made of stainless steel plate not less than 1.5mm thick, and the plexiglass window is set on the side. The front section of the water tank is about 850mm of spray section, and the spray pipe is provided with a guide nozzle so that the water is sprayed upwards. Water spray pipe made of stainless steel pipe welding, polished surface, G1 pipe connection for the threaded connection; drain pipe made of stainless steel pipe Φ48, the water after washing directly from the plastic pipe connected to the discharge outside the workshop.

|

Model

|

ZDX400

|

|

Capacity

|

400cans/min

|

|

Scope of use

|

Customized according to the shape of cans

|

|

Machine Weight

|

150KG

|

|

External Dimensions

|

4000*500*2300mm

|

For the whole can filling line, there are some

necessary

machines

you still need equip:

RO water treatment machine

Bottle blow molding machine

Bottle blow dryer

Bottle labeling machine

Code printer

Film shrink packing machine

company profile

ZhangJiaGang City BOTTLING MACHINERY Co.,Ltd. is located in Zhangjiagang city which is core of beverage machinery producer collection in China. Integrated the industry advantages and its own development in R&D, production, sales, after sales service,

BOTTLING MACHINERY is ready to serve more and more customers with our full range products and best service.BOTTLING MACHINERY is very critical in the choice of raw materials and spare parts. Korea 304 /316 stainless steel plate, ABB, SEW motors, Siemens, Mitsubishi, OMRON electrical control components, FESTO CAMOZZ the control valve, as well as international precision machining center for the fine quality of the machine foundation.

We are the supplier who can design and manufacture for all kinds beverage production plant (pure drinking water, mineral water,carbonated drinks, juice, tea and beer, etc.)

BOTTLING MACHINERY is ready to serve more and more customers with our full range products and best service.BOTTLING MACHINERY is very critical in the choice of raw materials and spare parts. Korea 304 /316 stainless steel plate, ABB, SEW motors, Siemens, Mitsubishi, OMRON electrical control components, FESTO CAMOZZ the control valve, as well as international precision machining center for the fine quality of the machine foundation.

We are the supplier who can design and manufacture for all kinds beverage production plant (pure drinking water, mineral water,carbonated drinks, juice, tea and beer, etc.)

Customer's service:

1. ZhangJiaGang City BOTTLING MACHINERY Co.,Ltd. can provide turn-key project for you, we can design the beverage factory plan according to your idea.

2. BOTTLING MACHINERY company have professional design team, our engineers can draw bottle samples and flow chart of workshop for you .

3. BOTTLING MACHINERY company can give you the best quotation for all kinds of beverage production, as long as you tell us which kind of drink you want to produce, what is your capacity(how many bottles one hour) what is you bottle material, pet or glass bottle or can, etc.

After service:

1. We send our engineers to your factory to help installing, commissioning and training, the engineers start from our factory area.

2. We supply below necessary documents with the goods shipping to you:

a. Machines layout drawing.

b. Electricity diagram.

c. Machine certificate.

d. General manual book/maintenance book.

3. After one year guarantee, the seller provides payable spare parts and technician's VISITING maintenance service.

1. ZhangJiaGang City BOTTLING MACHINERY Co.,Ltd. can provide turn-key project for you, we can design the beverage factory plan according to your idea.

2. BOTTLING MACHINERY company have professional design team, our engineers can draw bottle samples and flow chart of workshop for you .

3. BOTTLING MACHINERY company can give you the best quotation for all kinds of beverage production, as long as you tell us which kind of drink you want to produce, what is your capacity(how many bottles one hour) what is you bottle material, pet or glass bottle or can, etc.

After service:

1. We send our engineers to your factory to help installing, commissioning and training, the engineers start from our factory area.

2. We supply below necessary documents with the goods shipping to you:

a. Machines layout drawing.

b. Electricity diagram.

c. Machine certificate.

d. General manual book/maintenance book.

3. After one year guarantee, the seller provides payable spare parts and technician's VISITING maintenance service.

Packing&Delivery of BOTTLING

1. Our machines are packed by wooden case.

2. The delivery date of this machine is within 10-25 days after payment.

FAQ

Q:Are you a manufacturer or trade company?

A:We are a manufacturer in beverage bottling machine field more than 10 years, located at Leyu town, ZhangJiaGang, 2 hours from Shanghai, We will pick you up from Shanghai

Pudong Airport

to visit our factory.

Q:Do you have any certification?

A:SGS,ISO,CE etc

Q:What about the delivery time?

A:Usually 20-30 Working days for most kinds of machines

Q:What about the machine’s capacity?

A:1000 - 20000 bottles

per hour

based on 500ml bottle.

Q:The after-sale service

A:12 months warranty.

We can solve basic questions by telephone, email, whatsapp, wechat and video call.

Engineer will go to buyer's factory to install, test machines, and train buyer's staff how to operate, maintain machines.

Operating manuals will be sent with machines or by email.

We also have overseas service center

Q:If our bottle size changes, can we just do some adjustment on machine according to our new bottle?

A:Yes. Maybe you just need some spare little parts to change.

Q: If I want to purchase the machine, what information do I need to tell you?

A:a. What kind beverage you want to produce?

b. bottle volume? 250ml, 330ml, 500ml, 750ml, etc.?

c. Producing capacity requirement? How many bottles per hour?

d.Raw water analysis report .

e.Voltage and altitude.

Q:What kinds of product you supply?

A: Drink water/juice/carbonated drink filling line for bottle or can.

5 gallon/20L bottle water filling line.

Water treatment system.

Bottle blowing molding machine.

After packing system(label machine, PE film shrink packing machine, carton machine)

Sachet water packing line

Contact us

MS YOLANDA

5 years’ experience in foreign trade sales

Major in International business at

Yantai University

Whatsapp/Wechat: +8615190564896

Email:

yolanda@zjgbottlingmachinery.com

MR PHIL LANE

8 years’ experience in foreign trade sale

Major

Architecture, skilled CAD drawing, physical structure

China College English Test-6

Whatsapp/Wechat: +8615737466736

EMail: admin@zjgbottlingmachinery.com

EMail: admin@zjgbottlingmachinery.com

MR

ANDY

6 years in foreign trade sales

Major in mechanical engineering at university

Proficiency in photoshop drawing

Whatsapp/Wechat: +8613306249269

Email: sales1@zjgbottlingmachinery.com

Email: sales1@zjgbottlingmachinery.com

Hot Searches