- Product Details

- {{item.text}}

Quick Details

-

Machine Type:

-

Soap line, Automatic Soap Making Machine

-

Marketing Type:

-

New Product 2023

-

Application:

-

Chemical Industries

-

Function:

-

Soap Automatic Production Line

-

Finally products:

-

Bath Soap Toilet Soap

-

Keywords:

-

Soap Maker

-

Type:

-

Laundry Soap Bar Production Line

-

Material:

-

SUS304

-

Capacity:

-

100/500/1000/2000/3000 KG/H

-

After-sales Service Provided:

-

Online Support

-

Voltage:

-

220V/380V

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ocean lucky

-

Weight (KG):

-

5000

-

Machine Type:

-

Soap line, Automatic Soap Making Machine

-

Marketing Type:

-

New Product 2023

-

Application:

-

Chemical Industries

-

Function:

-

Soap Automatic Production Line

-

Finally products:

-

Bath Soap Toilet Soap

-

Keywords:

-

Soap Maker

-

Type:

-

Laundry Soap Bar Production Line

-

Material:

-

SUS304

-

Capacity:

-

100/500/1000/2000/3000 KG/H

-

After-sales Service Provided:

-

Online Support

-

Voltage:

-

220V/380V

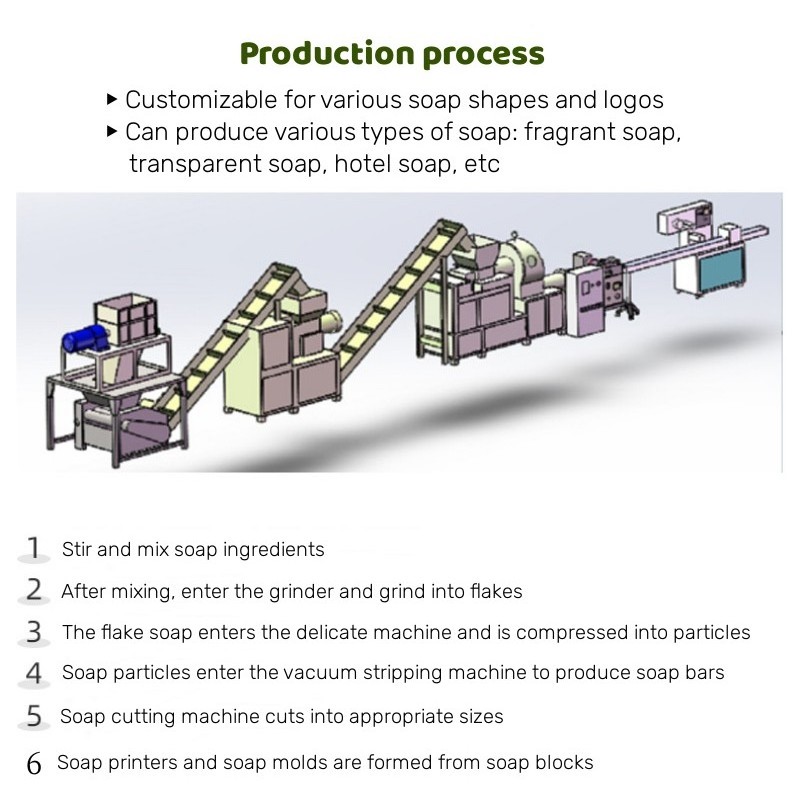

The laundry soap production line using oil as raw material mainly consists of three parts: saponification system, vacuum drying system, and molding line.

The laundry soap production line using oil as raw material mainly consists of three parts: saponification system, vacuum drying system, and molding line.

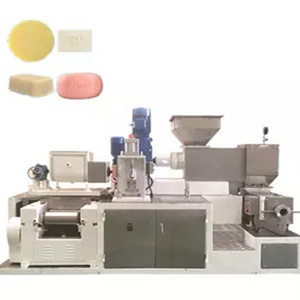

The laundry soap production line using soap particles as raw materials mainly includes mixing machines, three roller grinding machines, vacuum stripping machines, cutting machines, and conveyor belts.

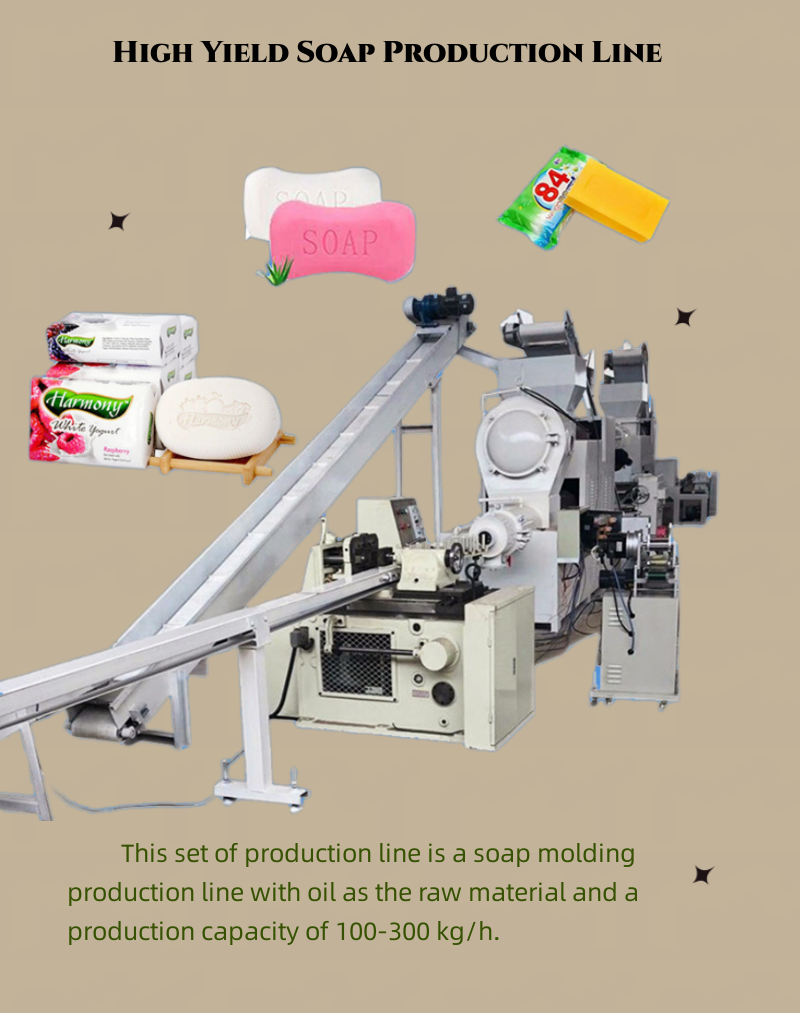

This production line is a soap forming production line with oil as the raw material and a production capacity of 100-300 kg/hour (the production capacity can be customized, 100-4000 kg/hour). After mixing raw materials, grinding, vacuum stripping, and printing, mid to high grade soap with a fatty acid content of 55-70% can be produced. The production line adopts a double-layer vacuum stripping machine, which can make the soap structure compact and not easy to dry and crack.

Production conditions:

1. Water: 1 cubic meter of circulating water (not consumed).

2. Electricity: 40 kW/h, 380 V, 50 Hz.

3. Workshop requirements: 20 meters long, 8 meters wide, and 3.5 meters high (including worker operation area).

4. Labor requirements: 3-5 people per shift.

Main technical parameters

| Mixing capacity (kg/time) | Capacity (mm) | Pneumatic system working pressure (MPa) | Mixing shaft speed (rpm) | Power (kW) | Boundary dimension (mm) | Weight (kg) |

| 70 | Φ780*1160 |

0.4-0.8 |

36 | 5.5 | 1850×810×1150 | 680 |