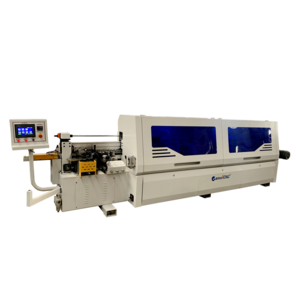

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

6600X1050X1750mm

-

Power (kW):

-

12.5

-

Weight (KG):

-

2500 kg

-

Panel Feed Speed(m/min):

-

26m/min

-

keywords:

-

Particle Board Production

-

Edge tape width:

-

12-65mm

-

Edge thickness:

-

0.4-3mm

-

Working pressure:

-

0.7mpa

-

Panel Width:

-

10-60mm

-

Belt material:

-

PVC, ABS, WOOD etc.

-

Gluing:

-

EVA and Pur quick soling

-

Customizable function:

-

vertical slot, side hole, bevel edge banding

-

After-Sales Service:

-

Free Replacement Parts

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

pmsk

-

Voltage:

-

AC380V/3PH/50HZ

-

Dimension(L*W*H):

-

6600X1050X1750mm

-

Power (kW):

-

12.5

-

Weight (KG):

-

2500 kg

-

Panel Feed Speed(m/min):

-

26m/min

-

keywords:

-

Particle Board Production

-

Edge tape width:

-

12-65mm

-

Edge thickness:

-

0.4-3mm

-

Working pressure:

-

0.7mpa

-

Panel Width:

-

10-60mm

-

Belt material:

-

PVC, ABS, WOOD etc.

-

Gluing:

-

EVA and Pur quick soling

-

Customizable function:

-

vertical slot, side hole, bevel edge banding

-

After-Sales Service:

-

Free Replacement Parts

Products Description

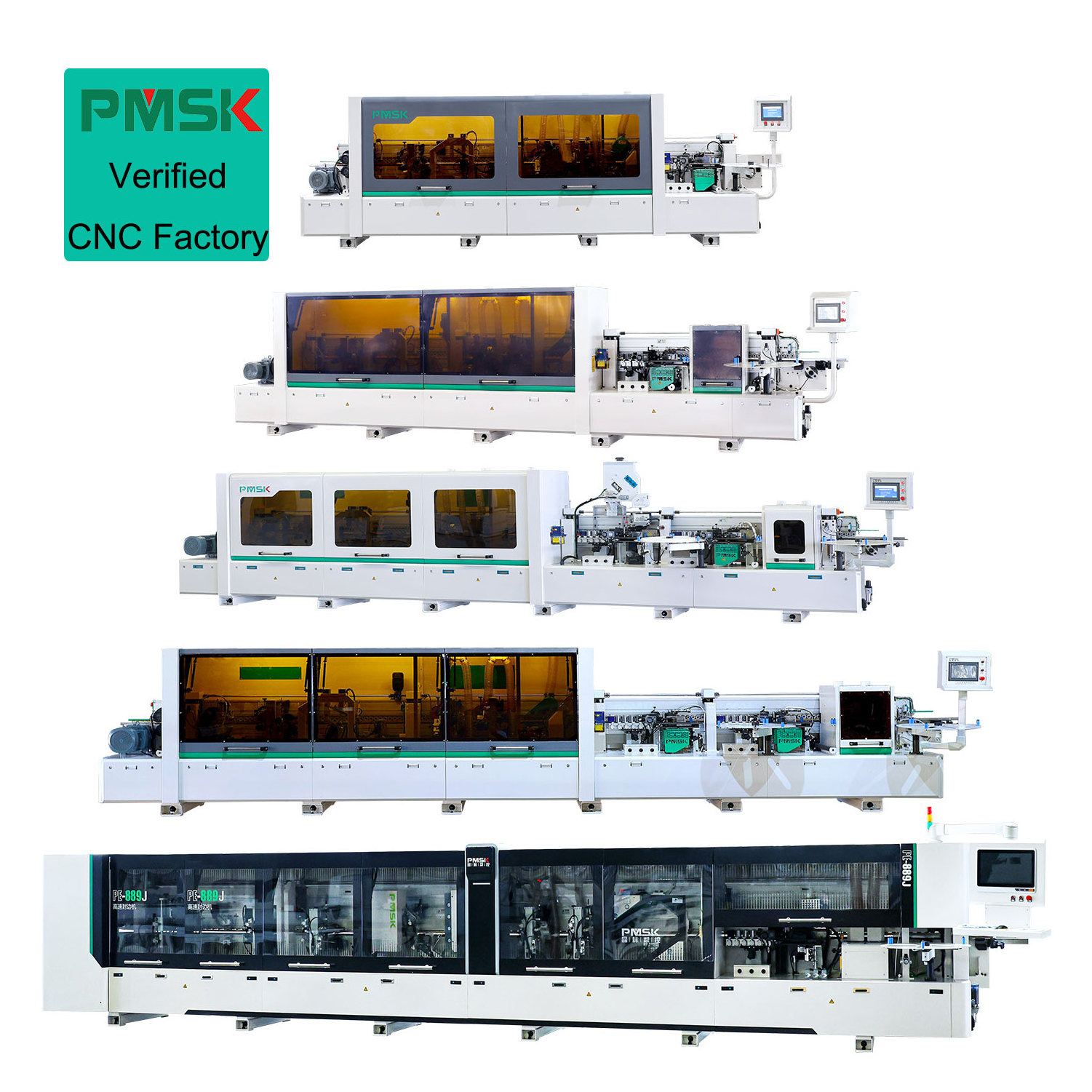

We are a factory. There are many models for you to choose from, and we can also customize them according to your requirements.

Examples: vertical slot, side hole,

bevel

edge

banding

and so on.

|

Model

|

Multiple models are available

|

Feeding speed

|

0-26m/min

|

||

|

Edge tape thickness

|

0.4-3mm

|

Working air pressure

|

0.7Mpa

|

||

|

Edge tape width

|

12-65mm

|

Dust extraction

|

∅100mm *7 pieces

|

||

|

Panel thickness

|

10-60mm

|

Size

|

Standard / Customization

|

||

|

Prices, Details, Function, Videos, Customized, etc.

|

|

Please Contact Us.

|

|

||

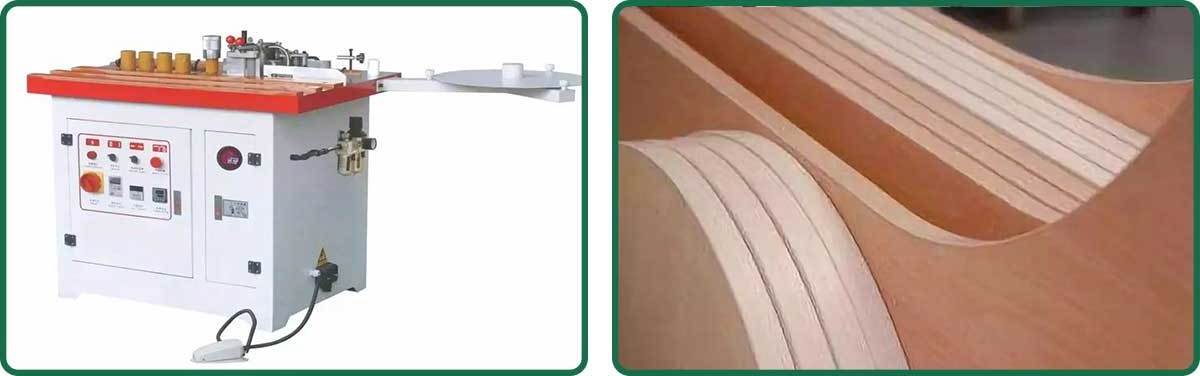

Pe332 (Curve/Straight)

Cabinet Automatic Portable Manual Edge Bander Machine Small Straight Curve Edge Banding Machine For Wood Based Panels Machinery

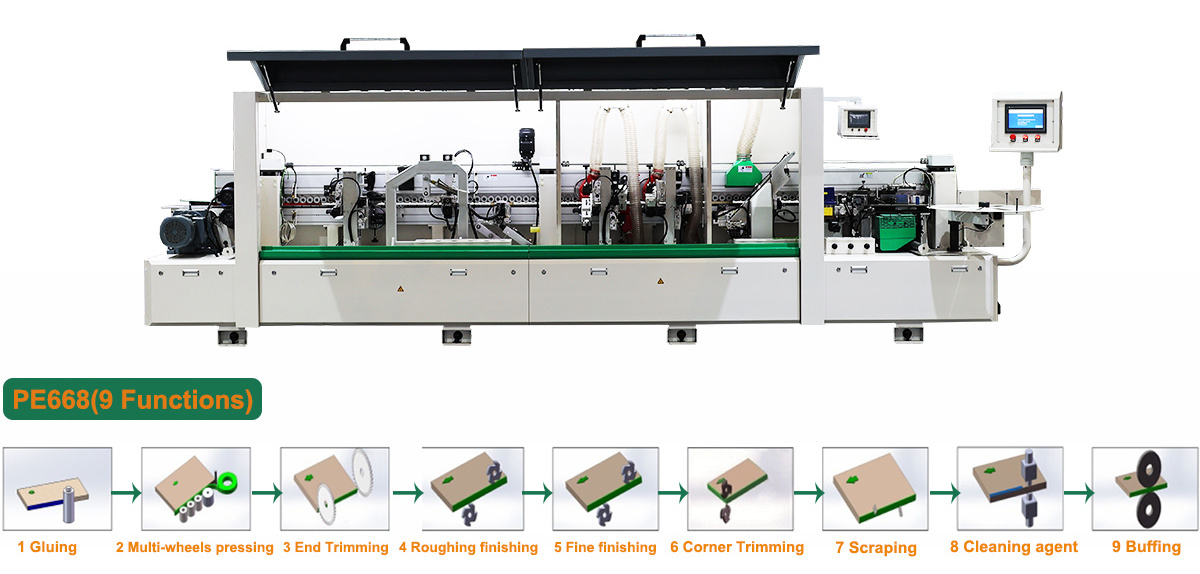

Pe668 (9 Functions)

1 Pre-milling, 2 Gluing, 3 Cutting start and end points, 4 Roughing finishing, 5 Fine finishing, 6 Rounded corner , 7 Scraping, 8 Cleaning agent, 9 Polishing.

Pe668j (11 functions)

1 Separating agent, 2 Pre-milling, 3 EVA glue, 4 Multi-wheels pressing, 5 Cutting start and end points, 6 Rough trimming, 7 Fine trimming , 8 Corner trimming, 9 Scraping , 10 Cleaning agents, 11 Polishing

Pe668j-1 (14 functions)

1 Separating agent, 2 Pre-milling, 3 EVA glue, 4 Multi-wheels pressing, 5 EVA gluing device, 6 Multi-wheels pressing, 7 Cutting start and end points, 8 Rough trimming, 9 Fine trimming , 10 Corner trimming, 11 Scraping , 12 Cleaning agents, 13 Polishing one, 14 Polishing two.

Pe889 (14 functions)

1 Infrared baking lamp, 2 Separating agent, 3 Pre milling, 4 Quick soling, 5 Multi wheels pressing, 6 Front and end cutting, 7 Rough trimming, 8 Pneumatic fine trimming, 9 4 Heads corner trimming, 10 Double pneumatic scraping, 11 Off-cut, 12 Flat scraping, 13 Cleaning agent, 14 Double pneumatic Buffing.

Problem Solver, Contact Us Without Loss

1, Are you worried about finding a

real manufacturer

?

2, Are you worried about the

quality

of the machine?

3, Are you worried about the

after-sales

problem of machinery?

4, Are you worried about

transportation

?

And so on.....

Don't worry,

contact us

. PMSK is a

MANUFACTURER

with 10 years' experience. All the machinery is manufactured by our factory. Rich

trade experience can solve all your problems.

One-on-one professional sales manager at your service.

Give Back To New And Old Customers

(10%off)

Welcome To Be Our Overseas Agent. (30%off)

Free Replacement Parts (Within 3 Years) (100%off)

The machine guarantee is 2 Years ,24 hours technical support online.

Welcome To Be Our Overseas Agent. (30%off)

Free Replacement Parts (Within 3 Years) (100%off)

The machine guarantee is 2 Years ,24 hours technical support online.

For more functional customization, please contact us.

Details Images

Control System

High quality touch screen,the system is stable, easy to operate, can be set in any language, and the edge sealing function can be switched quickly.

Spray Unit

Isolate the glue on the surface of the panel in up and bottom side.

Pre Milling (optional)

Using 2 pcs of high wear-resisting blades, work on the waved effect that is caused by precise panel saw. Ensure the edge of panel are good for banding

Up and Down Glue Pot

The spiral structure is adopted to feed the adhesive, so that the sheet material and the sealing material can be coated evenly.

Up Glue Pot (optional)

The glue pot can melt glue quickly and heat up quickly. It has good edge banding effect on PVC, high-gloss door panel and other plates.

Double Multi-Wheels Pressing

6 wheel pressing rollers, control for gluing amount, stable, prevent the dustinto gluing axis, make the edge tape bond with the panel perfectly.

End Trimming

End trimming mechanism through a precise guide track movement, adopts automatic tracking and high-frequency fast cutting structure to ensure the cutting surface smoothly.

Roughing finishing + Fine finishing

It is used for repairing the excess edge materials, adopting automatic tracking and high-frequency motor fast cutting structure to ensure the trimming plates smoothly.

Corner Trimming

The front and rear corners of the board are trimmed into small arcs to make them smoother, high precision guaranteed perfect look and touch.

Scraping

It is used to eliminate the wavy marks caused by the cutting process of trimming non-linear motion, and the size of the arc angle.

Cleaning agent

Cleaning the residual glue on the board.and removes any colour irregularities

Buffing

Buffing device adopts the board processed by the cotton polishing wheel, by end-polishing to make a more smooth surface.

Hot Searches