- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±1%, ±1%

-

Packaging Type:

-

Cups

-

Voltage:

-

380

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Boom

-

Dimension(L*W*H):

-

3300*710*1700mm

-

Weight:

-

700 KG

-

Keyword:

-

Cup Water Filling Sealing Machine

-

Productivity:

-

3000-10000cups/h

-

Filling Nozzles:

-

4/6/8/10

-

Cup Diameter:

-

30-120mm (Customized)

-

Filling Volume:

-

50 to 300ml

-

Sealing Film:

-

Plastic Roll Film, Plastic Pre-Cut Film, Aluminum Pre-Cut Film

-

Control System:

-

Touch Screen + PLC Control

-

Applicable:

-

Yogurt, Water, Ice Cream, Sauce, Honey, Seasoning, etc.

-

Feature:

-

High Precision Filling Level

Quick Details

-

Machinery Capacity:

-

8000BPH

-

Packaging Material:

-

Plastic, Paper, Metal

-

Filling Material:

-

Milk, Water, Oil, Juice, Powder

-

Filling Accuracy:

-

±1%, ±1%

-

Packaging Type:

-

Cups

-

Voltage:

-

380

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Boom

-

Dimension(L*W*H):

-

3300*710*1700mm

-

Weight:

-

700 KG

-

Keyword:

-

Cup Water Filling Sealing Machine

-

Productivity:

-

3000-10000cups/h

-

Filling Nozzles:

-

4/6/8/10

-

Cup Diameter:

-

30-120mm (Customized)

-

Filling Volume:

-

50 to 300ml

-

Sealing Film:

-

Plastic Roll Film, Plastic Pre-Cut Film, Aluminum Pre-Cut Film

-

Control System:

-

Touch Screen + PLC Control

-

Applicable:

-

Yogurt, Water, Ice Cream, Sauce, Honey, Seasoning, etc.

-

Feature:

-

High Precision Filling Level

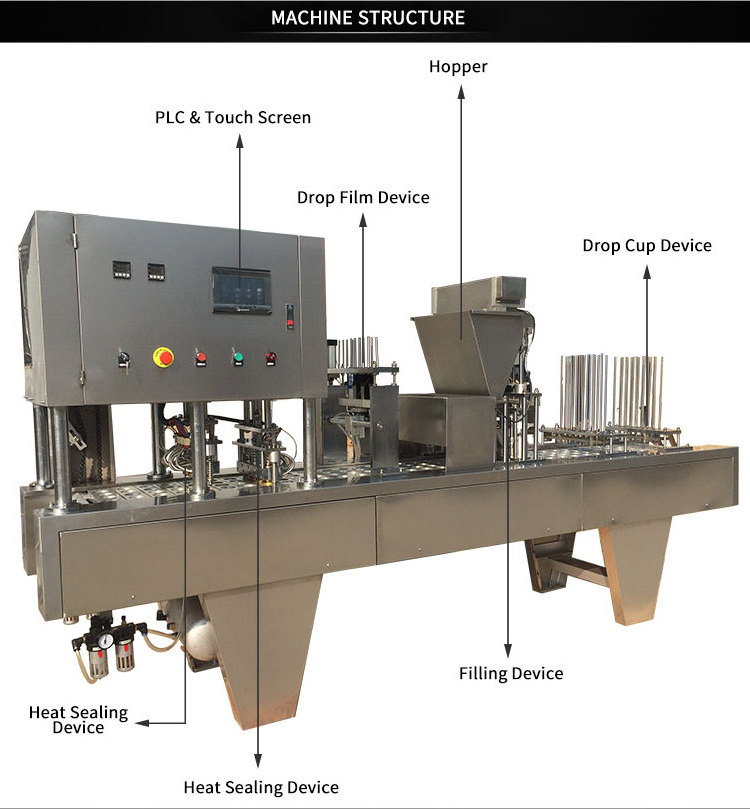

PRODUCT DESCRIPTION

Fully Automatic Plastic Liquid Water Cup Forming Filling Sealing Machine

Linear Cup Filling Machine is suitable for the production of various kinds of products such as yogurt, water, honey, milk, jelly, ketchup, fruit juice beverage products, etc. Auto falling the empty cups, empty cups detecting, auto quantitative filling product into the cup, auto film placing and sealing, auto discharging the finished product.

Suitable For:

Yogurt, Water, Ice Cream, Sauce, Honey, Seasoning, etc.

SPECIFICATIONS

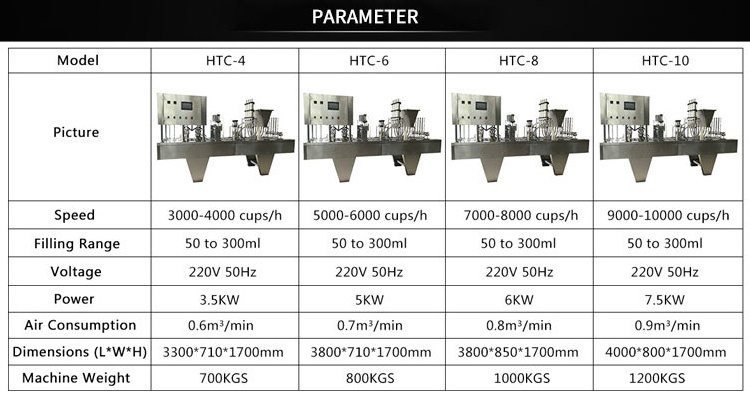

|

Model

|

HTC-4

|

HTC-6

|

HTC-8

|

HTC-10

|

|||

|

Output

|

3000-4000cups/h

|

5000-6000cups/h

|

7000-8000cups/h

|

9000-10000cups/h

|

|||

|

Filling Range

|

50 to 300ml

|

|

|

|

|||

|

Filling Heads

|

4 Heads

|

6 Heads

|

8 Heads

|

10 Heads

|

|||

|

Voltage

|

220V 50Hz

|

|

|

|

|||

|

Power

|

3.5KW

|

5KW

|

6KW

|

7.5KW

|

|||

|

Air Consumption

|

0.6 m3/min

|

0.7 m3/min

|

0.8 m3/min

|

0.9 m3/min

|

|||

|

Dimension (L*W*H)

|

3300*710*1700mm

|

3800*850*1700mm

|

3800*710*1700mm

|

4000*800*1700mm

|

|||

|

Machine Weight

|

700KG

|

800KG

|

1000KG

|

1200KG

|

|||

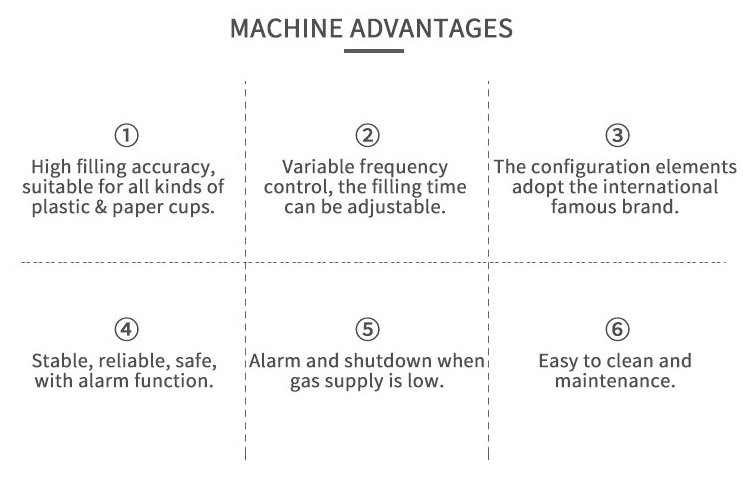

FEATURES AT A GLANCE

Working Process:

1. Falling Cups:

Cups drop down one by one automatically.

2. Filling Materials:

All parts are directly in contact with a product made of SUS-304.

3. Sucking Putting Foils:

Vacuum arm suck and put foils.

4. Press Plastic Cover:

Press the plastic cover tightly.

5. First Sealing:

0-300 degrees, can be adjusted.

6. Second Sealing:

0-300 degrees, can be adjusted.

7. Push-Out Finished Cups:

Push-out finished cups to a platform.

RECOMMEND PRODUCTS

PACKAGING

COMPANY PROFILE

Hot Searches