- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1788*1605*1294mm

-

Weight:

-

150 KG

-

Air Compressor:

-

0.3~0.8Mpa

-

Material:

-

304 Stainless Steel

-

Cutting Size:

-

customized

-

Package:

-

Plywood Case

Quick Details

-

Brand Name:

-

HeXu

-

Place of Origin:

-

Guangdong, China

-

Voltage:

-

220V/380V/Customized

-

Dimension(L*W*H):

-

1788*1605*1294mm

-

Weight:

-

150 KG

-

Air Compressor:

-

0.3~0.8Mpa

-

Material:

-

304 Stainless Steel

-

Cutting Size:

-

customized

-

Package:

-

Plywood Case

Cheese Cutter Cubic Cube Cutting Machine Cheese Dicing Machine

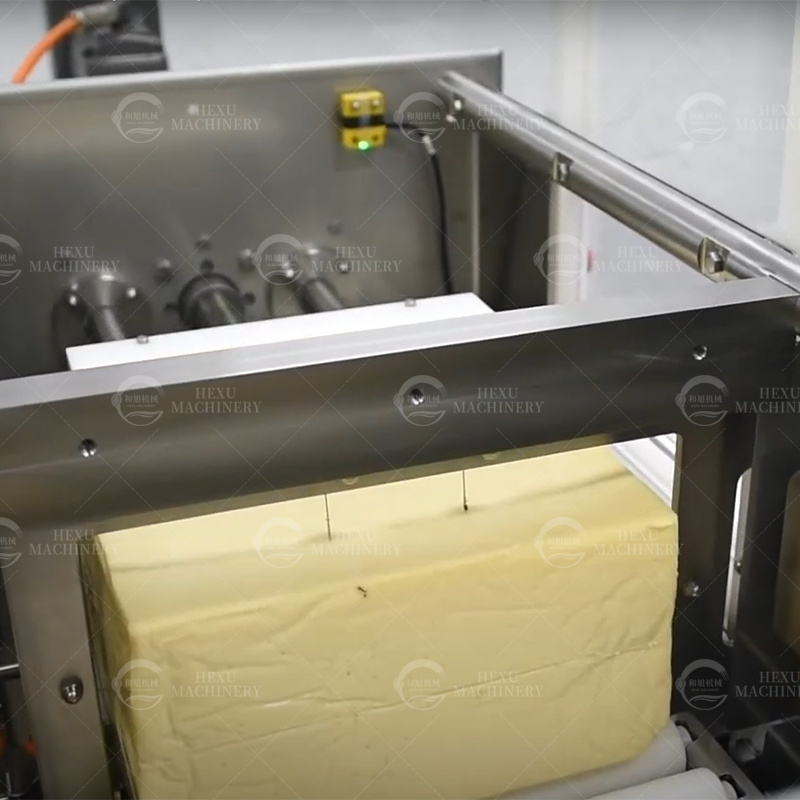

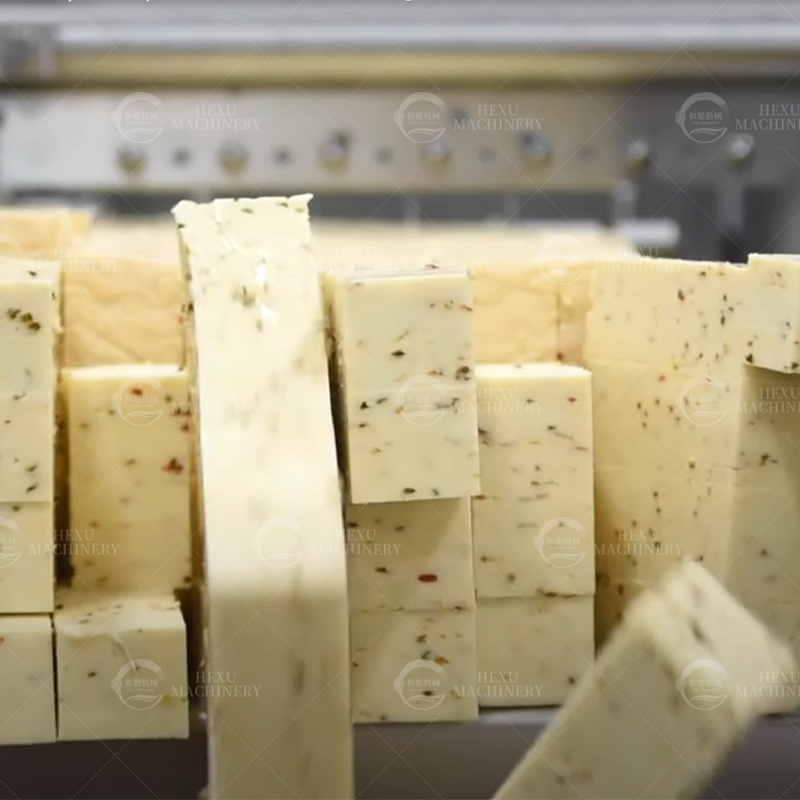

This Two-Stage Block Cutter is a robustly built cutter designed for years of trouble-free service. From tiny cubes to snack sticks, you can make what you want by utilizing this compact, stainless steel cutting machine.

Manufacturing Technique

|

Model

|

|

HX-40 Cutting Machine

|

|

|

|||

|

Dimension

|

|

1800*1600*1300mm or customized

|

|

|

|||

|

Air Compressor

|

|

0.3~0.8Mpa

|

|

|

|||

|

Cutting Size

|

|

Customized

|

|

|

|||

|

Machine Material

|

|

304 stainless steel

|

|

|

|||

|

Capacity

|

|

300-500kg per hour

|

|

|

|||

Since this machine is customized according to customer's cutting requirement, the price here is for deposit only. Please kindly contact us to get a latest quotation and more information.

Details Images

* Designed with the customer in mind, one operator to easily load blocks, precision cut, and discharge cheese portions.

* Quickly change between multiple cutting formats; customize cutting sizes; configurable designs handle a variety of cheeses.

* Discharging blocks “back-to-back” provides cleaner cuts. To help prevent breakage as cheese exits the 2nd stage harp, each block is fully discharged by the next block’s 2nd stage. The operator installs an “end run” pusher block to fully discharge the final cheese block.

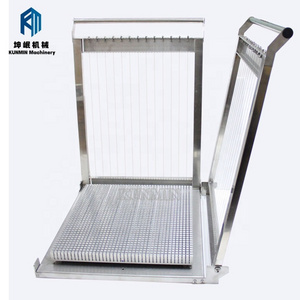

* Wire cutting can reduce friction and loss of cheese, and avoids the problem of softening cheese due to temperature rise caused by knife cutting.

* Quickly change between multiple cutting formats; customize cutting sizes; configurable designs handle a variety of cheeses.

* Discharging blocks “back-to-back” provides cleaner cuts. To help prevent breakage as cheese exits the 2nd stage harp, each block is fully discharged by the next block’s 2nd stage. The operator installs an “end run” pusher block to fully discharge the final cheese block.

* Wire cutting can reduce friction and loss of cheese, and avoids the problem of softening cheese due to temperature rise caused by knife cutting.

Application Scenarios

Recommend Products

Contact Information

Product Packaging

About Us

Hot Searches