Mobile Crushing and Screening complete set of equipment, including primary Crushing Station, secondary Crushing and Screening Station, belt conveyor, etc. . Each crushing station is an independent working unit, which can fulfill its different responsibilities. The belt conveyor is responsible for the material transfer and stacking between the crushing stations.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

TYM

-

Dimension(L*W*H):

-

1700*1732*1653mm

-

Weight:

-

7000 KG

-

Marketing Type:

-

New Product 2022

-

Product Name:

-

jaw type mobile crushing station

-

Jaw crusher model:

-

PE400*600

-

Size of Feeder Opening:

-

400*600mm

-

Max feeding size:

-

350mm

-

Size of output:

-

40-100mm

-

Capacity:

-

40-110tph

-

Motor power:

-

30-37kw

-

Feeder model:

-

GZT0724

-

Main belt machine model:

-

B650*6M

-

Transport size(L*W*H):

-

8600*2520*3770

Quick Details

-

Application:

-

mining used

-

Capacity(t/h):

-

15-60TPH

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

TYM

-

Dimension(L*W*H):

-

1700*1732*1653mm

-

Weight:

-

7000 KG

-

Marketing Type:

-

New Product 2022

-

Product Name:

-

jaw type mobile crushing station

-

Jaw crusher model:

-

PE400*600

-

Size of Feeder Opening:

-

400*600mm

-

Max feeding size:

-

350mm

-

Size of output:

-

40-100mm

-

Capacity:

-

40-110tph

-

Motor power:

-

30-37kw

-

Feeder model:

-

GZT0724

-

Main belt machine model:

-

B650*6M

-

Transport size(L*W*H):

-

8600*2520*3770

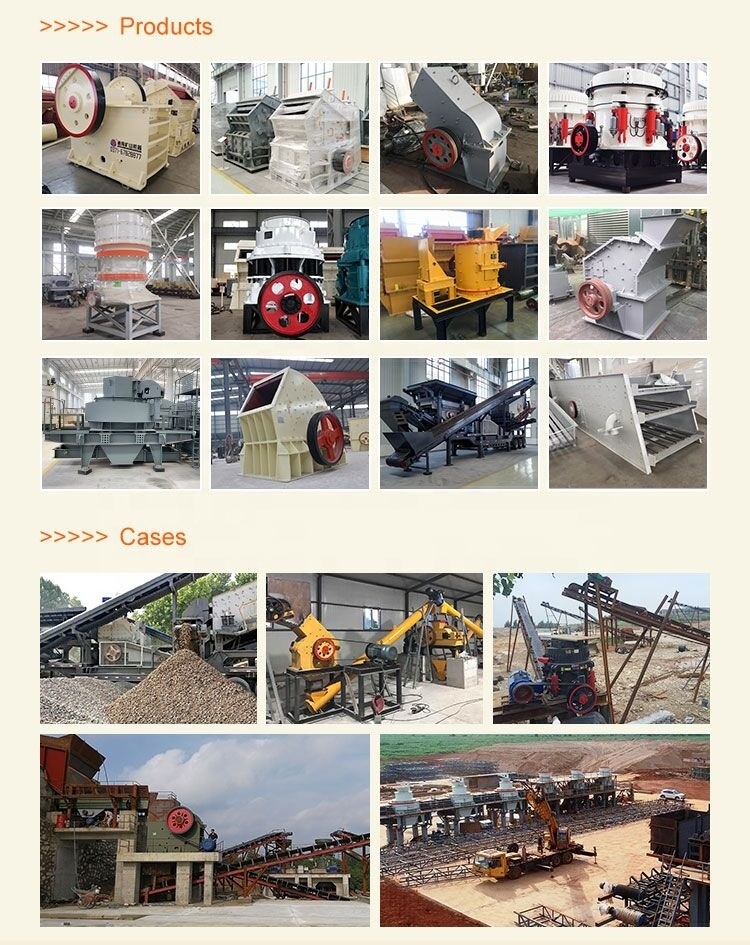

Product Introduction

Mobile Crushing Station

Mobile cone crusher station

Mainly used in the field of fine crushing. This device has a strong mobility, flexible and efficient, adaptable, flexible configuration and other advantages. Break the tradition in the design, using a new design concept, to produce higher hardness and finer granularity of sand and stone products, to meet the production needs of different users as a goal, careful configuration can be adjusted according to the actual needs of the crushing cavity, expanding the cone crusher mobile crushing station in the use of the field and use of the scope.

Work principle

When mobile cone jaw crusher station works, the materials are uniformly conveyed to the cone crusher by the feeder to be crushed. The finished materials after being crushed are screened out to different specifications by the circular vibrating screen and then exported by the conveyor. The moving cone crusher is convenient to move, simple to operate and can be broken once

Features

1.Be Mobile and flexible. Unit equipment installation integration, saving construction site space and investment costs.Reasonable on-board design, strong material, small turning radius, easy to move in the construction site, not restricted by rugged geographical environment, saving transport costs and time.

2.configuration of the cone crusher can be used for the fine crushing of materials, but also to meet the user's fine-grained finished product requirements.

3.Cone Crusher adopts the principle of static pressure, equipment vibration is small, reduce noise pollution.

4.The cone crusher works continuously and stably, has high crushing efficiency, convenient operation and long service life.

2.configuration of the cone crusher can be used for the fine crushing of materials, but also to meet the user's fine-grained finished product requirements.

3.Cone Crusher adopts the principle of static pressure, equipment vibration is small, reduce noise pollution.

4.The cone crusher works continuously and stably, has high crushing efficiency, convenient operation and long service life.

5.Equipment configuration is flexible, strong adaptability, can be a single unit of independent production, can also be formed with rough equipment cooperation.

Mobile impact crusher station

The Tyre-type Counterattack Crushing Mobile Station is a series of novel rock crushing equipment developed by General Mining Machine, which greatly expands the concept fields of coarse crushing and fine crushing. Eliminate the crushing site, environment,complex infrastructure configuration to bring customers crushing operations obstacles.Truly provide customers with simple,efficient, low-cost project operation hardware facilities. Mobile impact jaw crushing station is suitable for the construction waste crushing station, the mining area crushing operation and so on.

Work principle

Ordinary crusher in the raw materials to crusher crushing cavity, between the feeder and crusher must be placed on the surface of the belt conveyor for transmission, in the crusher station to which the mobile crusher belongs, the raw material feeder of the crusher is close to each other. In the middle, there is no need for the transmission of the conveyor. The raw materials of the mine surface are directly conveyed by the electric shovel to the feed port of the crusher, the raw materials will be injected into the crusher at a fixed speed, thus not only reducing the unnecessary process, but also greatly reducing the speed and cost of unnecessary trouble, each of the crusher, the crushing equipment works back and forth until all the raw materials are broken.

Features

1.Investment cost less

One-time complete crushing and screening operations, reduce equipment, less cost investment.

2.High value

Production line planner for your tailor-made configuration portfolio, with a small investment profits.

3.Applicability

According to the variety of raw materials, scale and requirements of finished products, a variety of combinations to meet different needs.

4.Independent

Complete sets of strong crushing stations at all levels are independent units, to complete their different responsibilities, reliable operation.

One-time complete crushing and screening operations, reduce equipment, less cost investment.

2.High value

Production line planner for your tailor-made configuration portfolio, with a small investment profits.

3.Applicability

According to the variety of raw materials, scale and requirements of finished products, a variety of combinations to meet different needs.

4.Independent

Complete sets of strong crushing stations at all levels are independent units, to complete their different responsibilities, reliable operation.

Application materials

Limestone, granite, marble, basalt, quartzite, river pebble, iron ore, copper ore, bluestone, sandstone, shale, construction waste, coal gangue, coal, ore tailings, artificial sand debris, etc.

Technical Parameter

Jaw type mobile crushing station parameters

|

Model

|

YDS50

|

YDS70

|

YDS100

|

YDS180

|

|

Feeder model

|

GZT0724

|

GZT0932

|

GZT0940

|

GZT1148

|

|

Jaw crusher model

|

PE400×600

|

PE500×750

|

PE600×900

|

PE750×1060

|

|

Main belt machine model

|

B650×6M

|

B800×7M

|

B1000×8M

|

B1000×11M

|

|

Maximum feed size(mm)

|

340

|

425

|

500

|

630

|

|

Outlet adjustment range(mm)

|

40~100

|

50~100

|

95~165

|

80~180

|

|

Production capacity(t/h)

|

10~35

|

25~60

|

30~85

|

72~150

|

|

Motor Power(kw)

|

43

|

57

|

72

|

147

|

|

Transport size(L×W×H)(mm)

|

8600×2520×3770

|

9600×2520×3500

|

11097×3759×3500

|

13300×2900×4440

|

|

Separator(optional)

|

RCYD

|

RCYD

|

RCYD

|

RCYD

|

|

Mobile frame

|

Biaxial

|

Biaxial

|

Biaxial

|

Triaxial

|

Counterattack mobile crushing station parameters

|

Model

|

YDS50

|

YDS70

|

YDS100

|

YDS180

|

|

Vibrating screen type

|

4YA1235

|

4YA1545

|

4YA1548

|

3YA1848

|

|

Crusher model

|

PF1007

|

PF1010

|

PF1214

|

PF1315

|

|

Outlet belt conveyor model

|

B650×7M

|

B800×7M

|

B1000×10M

|

B1000×11M

|

|

Return belt conveyor model 1

|

B650×9M

|

B800×10M

|

B1000×10M

|

B1000×11M

|

|

Return belt conveyor model 2

|

B650×5M

|

B800×6M

|

B1000×6M

|

B1000×7M

|

|

Transport size(L×W×H)(mm)

|

10800×2480×4170

|

12200×2743×4200

|

12500×2900×4200

|

13000×3100×4300

|

|

Tire configuration

|

Biaxial

|

Biaxial

|

Biaxial

|

Triaxial

|

Cone—type mobile crushing station parameters

|

Model

|

YHPY—200

|

YHPY—300

|

YHPY—400

|

YHPY—500

|

|

New type of HPY cone crusher

|

HPY—200

|

HPY—300

|

HPY—400

|

HPY—500

|

|

Cone crusher power(kw)

|

160

|

225

|

315

|

400

|

|

Maximum feed size(mm)

|

185

|

230

|

300

|

330

|

|

Minimum discharge port(mm)

|

5—10

|

6—13

|

6—13

|

8—16

|

|

Production capacity(t/h)

|

50—250

|

100—400

|

120—500

|

150—700

|

|

Vibrating screen type

|

3YK1854

|

3YK2160

|

3YK2260

|

3YK2460

|

|

Vibrating screen power(kw)

|

22

|

30

|

37

|

37

|

|

Sieve belt conveyor

|

B800L6

|

B1000L6

|

B1000L8

|

B12008

|

|

Match power(kw)

|

5.5

|

7.5

|

7.5

|

11

|

|

Hydraulic system

|

YZ20

|

YZ30

|

YZ30

|

YZ30

|

|

Frame configuration

|

Biaxial

|

Triaxial

|

Triaxial

|

Triaxial

|

Work Site

Hot Searches