- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Zhongxiang

-

Product name:

-

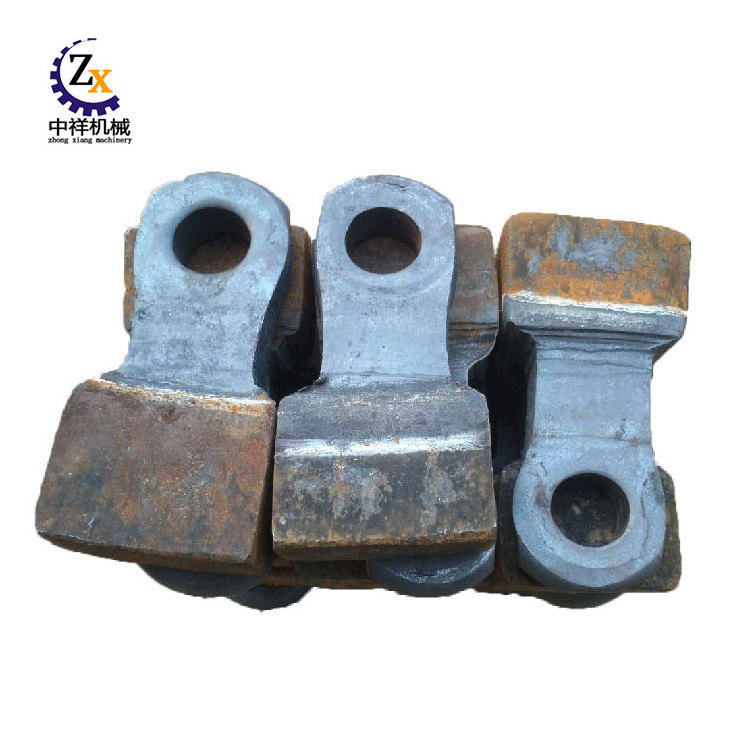

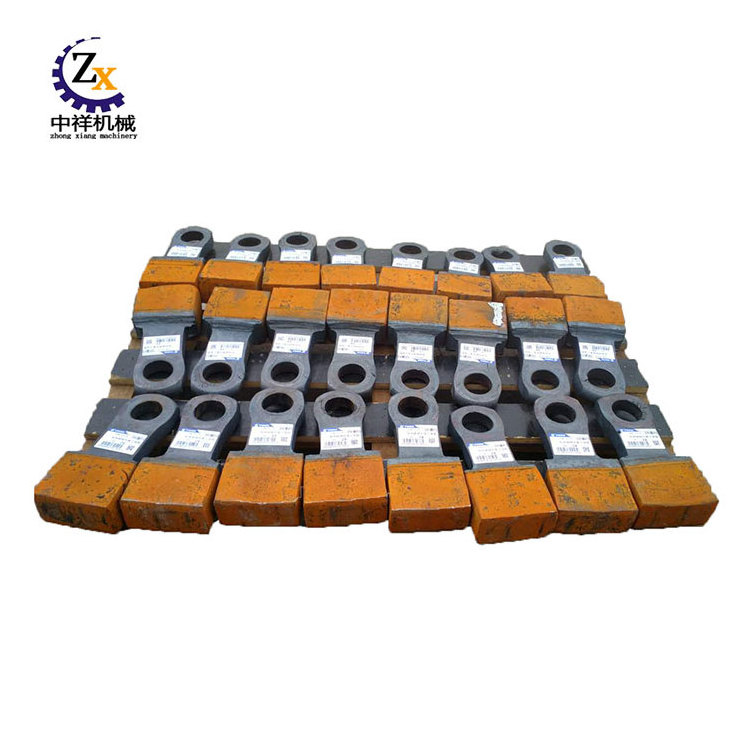

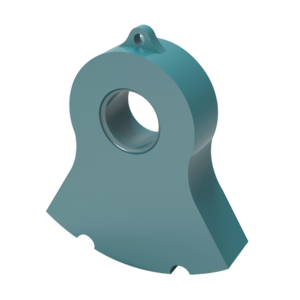

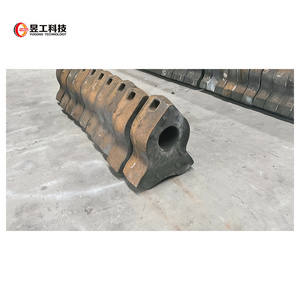

High Chrome Alloy Bimetal Hammer As Crusher Spare Parts

-

Name:

-

Crusher hammer

-

Application:

-

Ore Drilling

-

Usage:

-

Crushing Etc

-

Color:

-

Customized

-

Advantage:

-

Durable

-

Size:

-

Customize Size

-

Packing:

-

Wooden Case

-

Quality:

-

High Level

-

Standard:

-

ISO

Quick Details

-

Weight (KG):

-

9

-

Marketing Type:

-

Hot Product 2022

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Zhongxiang

-

Product name:

-

High Chrome Alloy Bimetal Hammer As Crusher Spare Parts

-

Name:

-

Crusher hammer

-

Application:

-

Ore Drilling

-

Usage:

-

Crushing Etc

-

Color:

-

Customized

-

Advantage:

-

Durable

-

Size:

-

Customize Size

-

Packing:

-

Wooden Case

-

Quality:

-

High Level

-

Standard:

-

ISO

Hammer Crusher Wear Part High Chrome Alloy Bimetal Hammer As Crusher Spare Parts

|

|

|

|

|

|

|

|

|

|

|

1.How is the quality of your products?

Hammer Crusher Wear Part High Chrome Alloy Bimetal Hammer As Crusher Spare Parts is manufactured strictly according to national and international standard, and we take a test on every equipment before delivery. 2.Guaranteed: If products’quality is not consistent with the description as we described or the promise before you place order, we promise 100% refund. 3.How about price? Yes, we are factory and be able to give you the lowest price than market one, and we have a policy that “ for saving time and absolutely honest business attitude,we quote as low as possible for any customer, and discount can be given according to quantity”. 4.Service and Payment Terms? A. We usually accept T/T, L/C; B. T/T: 30% in advance as down payment, the balance before delivery; C. We take pictures of finished products before delivery. 5. What’s the additional features of your company? A: We have our own laboratory in the company, so the clients can take some samples to perform experiments on the spot. And our engineers will provide the best advice and choice for our clients. |

|

|

|

Hot Searches