- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HYD

-

Width:

-

63.5mm

-

Length:

-

600mm,1200mm,2400mm......

-

Model Number:

-

63series

-

surface:

-

can be punched, can be galvanized, can be pray painted

Quick Details

-

Thickness:

-

4mm

-

Standard:

-

ASTM, DIN, GB

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

HYD

-

Width:

-

63.5mm

-

Length:

-

600mm,1200mm,2400mm......

-

Model Number:

-

63series

-

surface:

-

can be punched, can be galvanized, can be pray painted

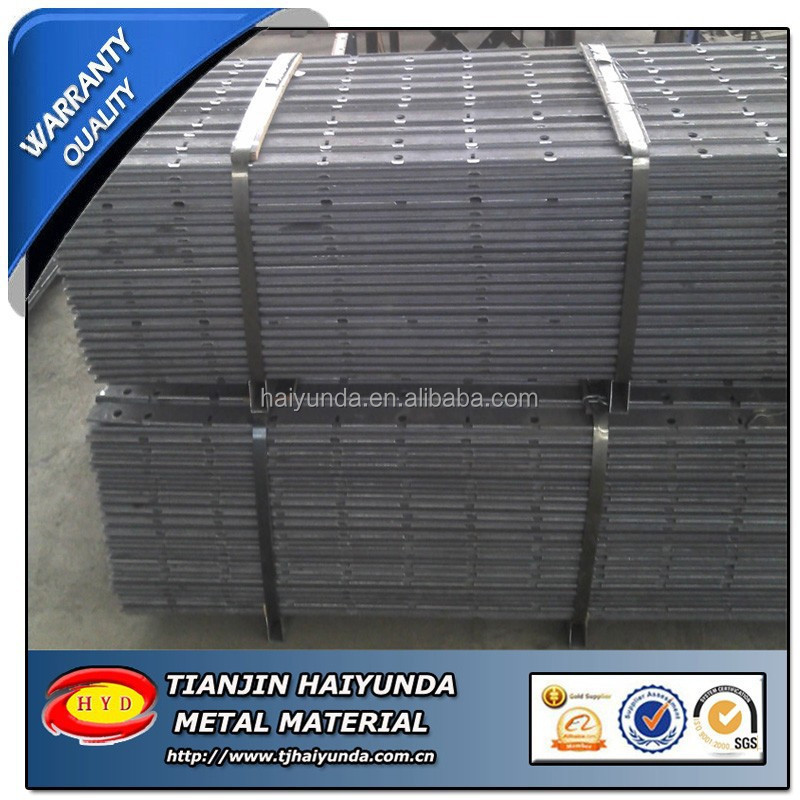

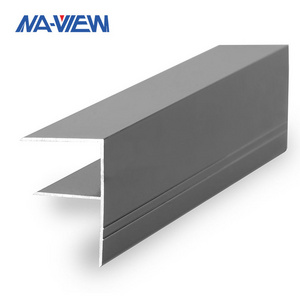

F profile bar for concrete formwork

Specifications

1.Material:45# steel

2.Surface:F Type Flattening

F profile bar for concrete formwork

Concrete Formwork System Steel Profile

1.Material:ASTM1045 or Q235 2.Shape: F Steel profile 3.Technical processing:hot rolled

CONCRETE FORMWORK SYSTEM

Production Process :

F shape material :ASTM 1045

wel ding technology

Power painted:

Install the board:

Packing:

construction site:

Related accessories:

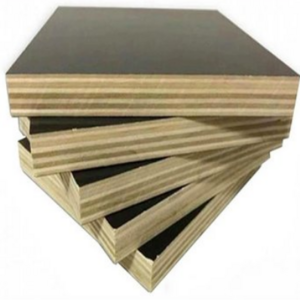

The concrete form panels are kind of systemized formwork, easy to install and to dismantle for the reinforced concrete construction in any type. The structure of the panels is conveniently designed for various functions, enabling the panels to be reused repeatedly, helping save the costs on materials and reduce the times for work by simplifying and accelerating the process. Consequently it can cut down on the labor costs and expenses. Basic and standard products as well as various products for different types and sizes of constructions are available from manufacturing. Recycling the panel after its life-span can help reduce costs, because we can remove plywood, adjust the frame and the angle, get rid of the impurities, carry out coloring and finally attach the new plywood. The recycled forms still perform as good as the new ones, with substantially reduced costs. Other types of recycled panel are those who combine the recycled frames and the used plywood which is still in good condition.