- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

DP ROLLER

-

Core Components:

-

Roller

-

Weight (KG):

-

300 kg

-

Product name:

-

Gravity Pallet Roller Conveyor

-

Usage:

-

Conveying Pallet

-

Frame Material:

-

SUS304/Carbon Steel

-

Application:

-

Warehouse

-

Roller material:

-

SUS304/Carbon Steel

-

OEM:

-

Accept

-

Keyword:

-

Gravity Pallet Racking

-

Loading capacity:

-

500-3000kgs

Quick Details

-

Power:

-

0W

-

Warranty:

-

1 Year

-

Width or Diameter:

-

60/76/89mm

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

DP ROLLER

-

Core Components:

-

Roller

-

Weight (KG):

-

300 kg

-

Product name:

-

Gravity Pallet Roller Conveyor

-

Usage:

-

Conveying Pallet

-

Frame Material:

-

SUS304/Carbon Steel

-

Application:

-

Warehouse

-

Roller material:

-

SUS304/Carbon Steel

-

OEM:

-

Accept

-

Keyword:

-

Gravity Pallet Racking

-

Loading capacity:

-

500-3000kgs

Products Description

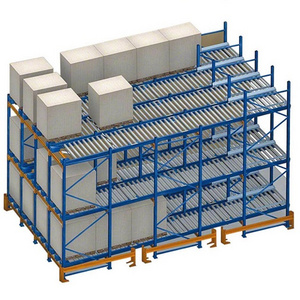

DPR1000 Gravity Roller Conveyor For Gravity Pallet Racking

Gravity

racking

are one of the derivatives of beam-type

racking

. The structure of the

racking

is similar to that of beam-type

racking

except that roller-type rails are installed on the beams, and the rails are inclined at 3-5°.

The pallet are transported to the shelf inlet by forklift, and with its own weight, the pallet automatically slides from the entrance to the pickup port at the other end. Gravity

racking

are first-in first-out storage methods.

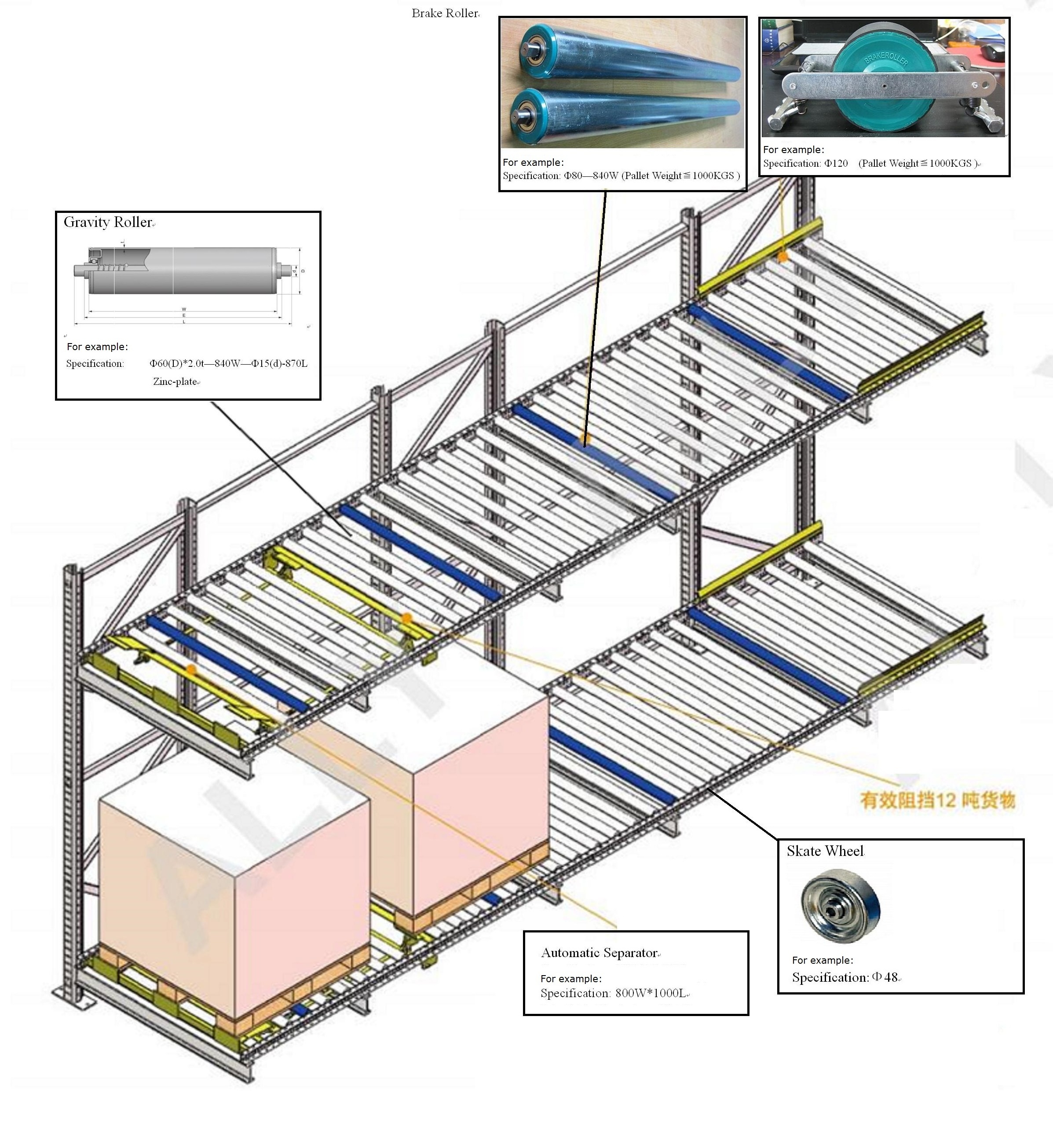

1.The goods are deposited from the high end, slide to the low end, and take out from the low end. During the cargo sliding process, dampers are installed on the slide way to control the cargo sliding speed to be kept within a safe range. There is a separator at the shipping end of the chute, and the conveying machinery can smoothly take out the goods at the position of the first board.

2. The goods follow the first-in first-out order. The shelf has a high storage density and has a flexible matching function.

3. It is suitable for storage operations with pallets as carriers. The goods are neatly stacked and provide a better solution for the storage of large and heavy objects. The storage space utilization rate is more than 75%, and only one import and export channel is required;

4. Gravity

racking

are very environmentally friendly, all adopt non-powered form, no energy consumption, low noise, safe and reliable, and can operate at full load.

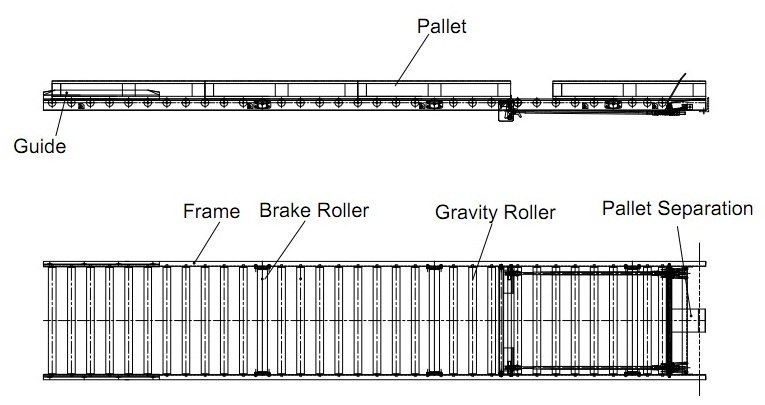

General technical data

|

No.

|

Part

|

Description

|

|

1

|

Roller

|

Gravity roller (DP1200 or DP1300)

|

|

2

|

Frame

|

Carton Steel(Powder-coated) / Stainless Steel

|

|

3

|

Brake Roller

|

DP-BW or DP-BI

|

|

4

|

Pallet separator

|

Steel, Zinc-plate

|

|

5

|

Guide

|

Steel, Powder coating

|

Structure Drawing

Hot Searches