- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

SY16

-

Thickness:

-

0.3-12MM

-

Size:

-

350-1680MM

-

Product name:

-

Plastic sheet board for thermoforming

-

Type:

-

OEM Parts

-

Color:

-

White or any color

-

Raw material:

-

100% Virgin Material

-

Design:

-

Engineer

-

Application:

-

Vacuum forming product

-

Surface:

-

Matte,high glossy,smooth

-

Quality:

-

High-quality

-

Shipping:

-

Air or sea

Quick Details

-

Processing Service:

-

Cutting, Moulding, Thermoforming

-

Place of Origin:

-

China

-

Brand Name:

-

Shunyue

-

Model Number:

-

SY16

-

Thickness:

-

0.3-12MM

-

Size:

-

350-1680MM

-

Product name:

-

Plastic sheet board for thermoforming

-

Type:

-

OEM Parts

-

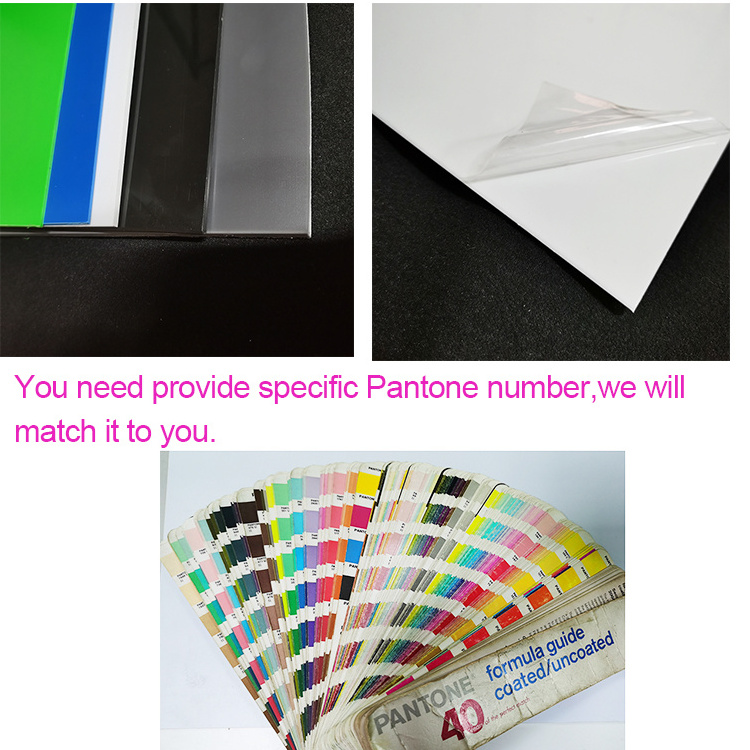

Color:

-

White or any color

-

Raw material:

-

100% Virgin Material

-

Design:

-

Engineer

-

Application:

-

Vacuum forming product

-

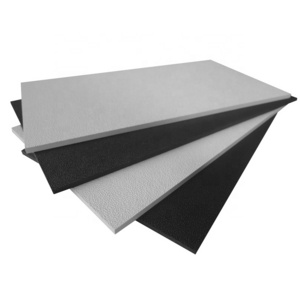

Surface:

-

Matte,high glossy,smooth

-

Quality:

-

High-quality

-

Shipping:

-

Air or sea

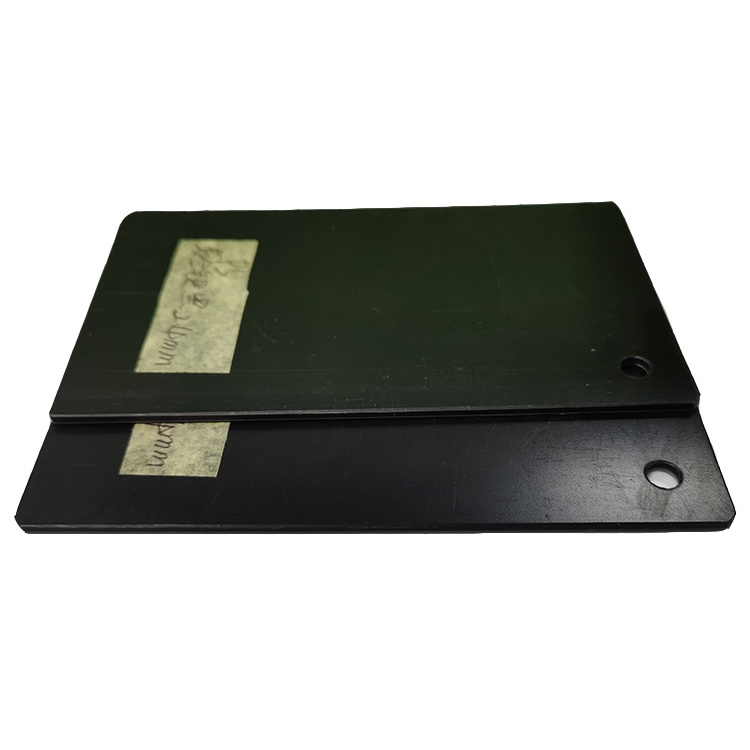

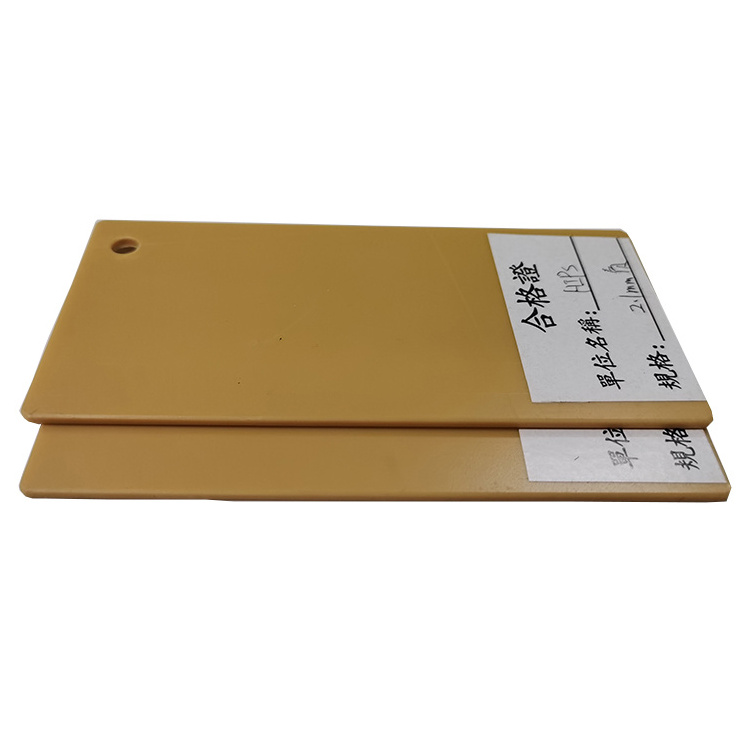

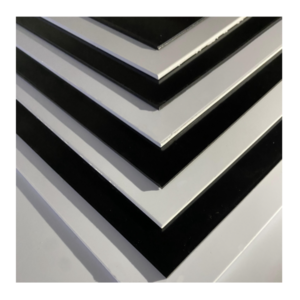

Vo Fire resistant thick ABS HIPS PP Plastic sheet board for thermoforming

|

PS,PP,ABS sheet |

|

|

Color |

White,Ivory,Black,green,red and any color as you want(provide pantome number) |

|

Diameter |

0.3-12mm |

|

Shape |

Plastic sheet, plastic roll and any shape as you want(CAD drawing ) |

|

Certification |

ISO9001:2015 |

|

Free sample |

1 or 2 PCS A4 size sample |

|

Package |

PE film+composite paper(small size), PE film(large size) |

|

Advantage |

Factory price |

Note:when you konw is not sure which material as you need, you can tell me funtion of sheet,we will give you suggestion.

PP: E asy to dye, corrosion-resistant, surface hardness, good heat resistance, large molding shrinkage. It is widely used in the packaging of auto parts, home appliances and daily necessities.

PS: Anti-static,conductive,E xcellent electrical insulation, general strength, easy to be brittle . Suitable for making electronic parts package , decorative parts, equipment enclosure, lampshade.

ABS : H ard, easy to press out, easy to dye, flame retardant, impact resistant, good wear resistance, good electrical insulation ,which is an environmentally friendly material. Suitable for packaging,electronic parts, auto parts, home appliance parts, computer parts, toys, vacuum forming Plastic products(Plastic tray,outside enclosure,box) , etc .

Packaging details:Step 1: Use PE film as inner packing for sheets

Step 2: Then packed with 3 layers composite film

Step 3: PE film again as the outer packing.

Port:shenzhen,guangzhou

Lead time:

|

Quantity(Sets) |

1 - 5000 |

5000 - 10000 |

>10000 |

|

Est. Time(days) |

7 |

14 |

To be negotiated |

1.21years vacuum thermoforming work experie n ce. And Support OEM ODM parts

2.The material we can supply ABS,PS,PP,PE,Acrylic,PET,PETG,TPV for your choice.

3.. Extruded plates, raw materials can be Adjust the corresponding formula according to different needs, which can solve the function of difficult plastic products.

4. Use three-axis and five-axis cutting machines to automatically cut to ensure the correct size of the product.

5. Products are widely applied in toy, catering, auto, mechanism, household appliance, tourism, printing, medical equipment, architecture, touring, advertising, furniture etc.

6. Extremely adaptive to customer design needs