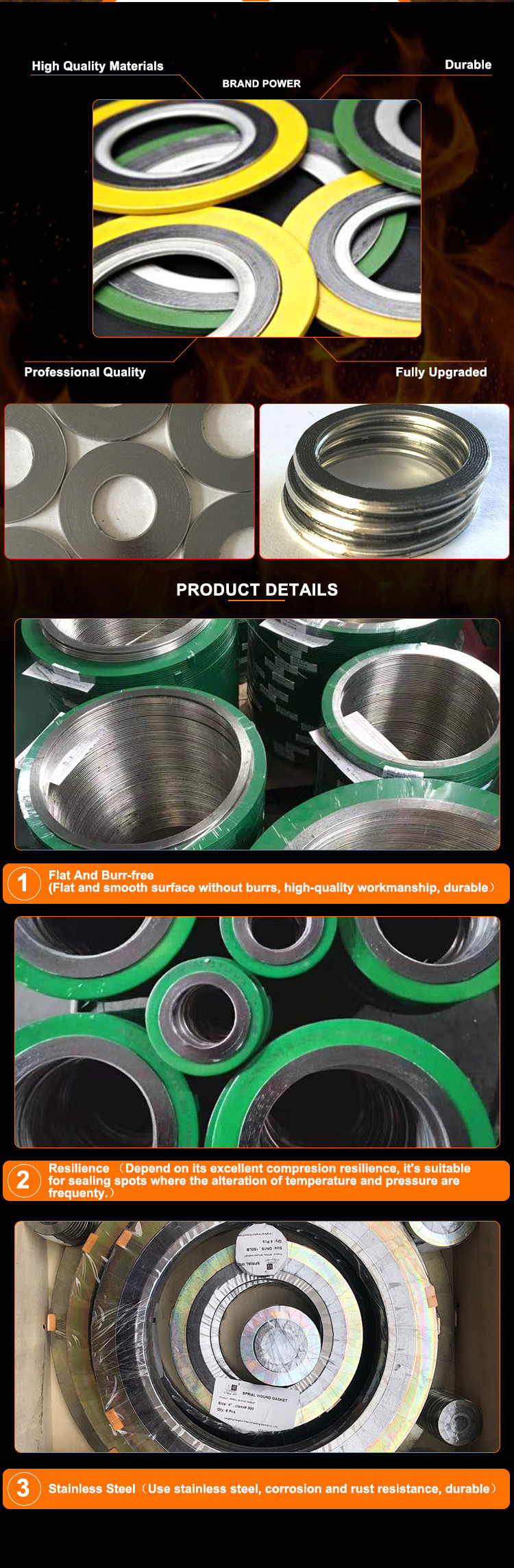

- Product Details

- {{item.text}}

Quick Details

-

Standard or Nonstandard:

-

Standard

-

pipe flange gasket:

-

3 inch metal rings

-

flat face washer:

-

metal cock and ball rings

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Fangdun

-

Model Number:

-

Spiral Wound Gasket

-

Standard or Nonstandard:

-

Standard

-

pipe flange gasket:

-

3 inch metal rings

-

flat face washer:

-

metal cock and ball rings

Different specifications have different prices

Please consult customers for specific prices

Product Description:

Product Description:

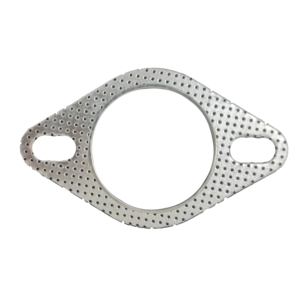

Spiral Wound Gaskets are winding by "V" shaped metallic strip and soft non-metallic filler.

According to the requestment, the gaskets can be within inner and outer rings for improving the gaskets handling, fitting and versatility.

Depend on its excellent compresion resilience, it's suitable for sealing spots where the alteration of temperature and pressure are frequenty.

Basic Type:

Basic type gasket: inner and outer diameters are reinforced with several piles of metal without filler to give greater stability and better compression characteristics.

Suitable for tongue and groove, male and famale or grooved to flat face flange essemblies.

Inner Ring Type:

Solid inner metal ring acts as a compression stopper. To prevent accumulation of solids, reduce trubulent flow of process fluids and minimize erosion, damages of gasket between flange bore and the inside diameter, the annular space is filled up by solid inner metal ring;

Suitable for male and female pipe flanges.

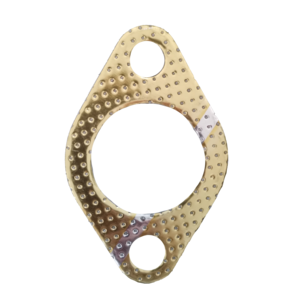

Outer Ring Type:

Solid outer accurately locates the gasket on the flange face to give the additional radial strength to prevent gasket blowout and acts as a compression limiter. In case of installing the outer ring, it is very easy to install the gasket to flange face because the end of outer ring will touch at bolts;

Suitable for use with flat face and raised face flanges. For class 900 and above an internal ring is recommended.

Inner & Outer Ring Type:

An inner ring and outer ring type gasket will give an additional compression limiting stopper for gasket inner and outer side. It will prevent the corrosions on flange face at annular space;

Suitable for use with flat face and raised face flanges and specified for high pressure and temperature service, Class 900 and above or where corrosive or toxic media are present.

|

Metal Winding & Inner Ring |

Filler Materials |

Outer Ring Materials |

|

As Standard SS304(L) Others Stainless Steel 309 310 317L 321 347 Alloy 20 Monel 400 Titanium 1,2,7 Nickel 200 Inconel 600,635 Incoloy 800,825 Hastelloy B2 C276 Duplex 31803 Copper Inner ring: Carbon steel also abailable |

Flexible graphite PTFE Mica Ceramic Non-asbestos |

As Standard Carbon Steel others 304 (L) 316 (L) 317 310 321 347 410 Alloy 20 Monel 400 Titanium 1,2,7 Nickel 200 Inconel 600,635 Incoloy 800,825 Hastelloy B2 C276 Duplex 31803 |

If you are interested, click here to cantact me.

Hot sell flexible graphite reinforced gaskets with the best quality

Features:

Sprail-Wound gasket:

1.Graphite,PTFE as filler

2.Materials:316,304,CS

3.Pressure:32Mpa

4.ISO9001 certified

Products Features

-

Wide range of applicable working condition,high temperature and high pressure resistance,applicable to super low temperature and vacuum condition.Chemical resistant gasket is available under various medium,through change of composition of gasket.

-

Strong stress compensation,stable and reliable sealing performance even under frequent pressure fluctuation condition.

-

Perfect sealing performance.

-

Normal requirement of flange surface finishing which contact with gasket.

-

Easy installation and low pre-tightening stress of gasket.

|

Pressure |

≤4.0MPa |

|

Temperature |

≤260 |

|

Gasket coefficient |

m=2.5 |

|

PH |

0-14 |

|

Min. specific pressure |

y=20MPa |

1. We are a direct manufacturer and our priority is your complete satisfaction.

2. Logo printing: we can print any logo as per your requires on the case.

3. We take care of each order from start to finish. All emails will be answered in 1 day

4. No matter what's your order quantity,we will offer the same attention to our quality and service

5. Delivery & lead time: all delivery methods are ok, and our lead time is quite short. Usually, our lead time around 7 days, depending on the quantity.

6.Packages: Available for ploy bag and carton box