- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Stirrup Bending Machine

-

Single wire diameter:

-

Rebar 5-12mm; Round wire 5-14mm

-

Double wire diameter:

-

Rebar 5-10mm; Round wire 5-10mm

-

Maximum bending angle:

-

+180°

-

Maximum towing speed:

-

110m/min

-

Maximum bending speed:

-

1000°/sec

-

Length accuracy:

-

±1mm

-

Average power:

-

5kw/h

-

Weight:

-

2200kgs

-

Size:

-

3850x1200x2200mm

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

DAPU

-

Weight (KG):

-

1800

-

Product name:

-

Stirrup Bending Machine

-

Single wire diameter:

-

Rebar 5-12mm; Round wire 5-14mm

-

Double wire diameter:

-

Rebar 5-10mm; Round wire 5-10mm

-

Maximum bending angle:

-

+180°

-

Maximum towing speed:

-

110m/min

-

Maximum bending speed:

-

1000°/sec

-

Length accuracy:

-

±1mm

-

Average power:

-

5kw/h

-

Weight:

-

2200kgs

-

Size:

-

3850x1200x2200mm

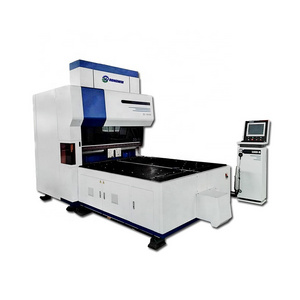

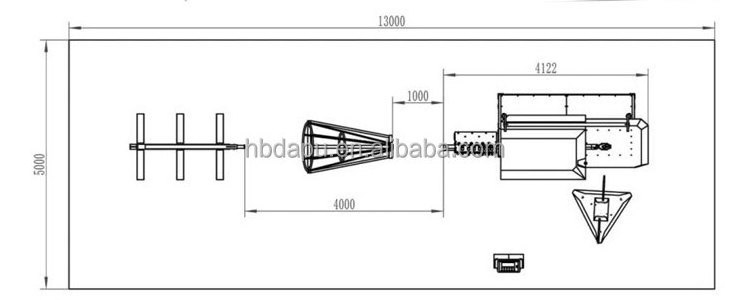

Automatic coil feeding automatic stirrup bender

The CNC automatic stirrup bending machine can process single/double steel bars. Single steel bar processing capacity range: 5-14mm. Dual steel bar processing capacity range: 5-10mm.

The processing graphics can be visualized, various graphics can be processed simultaneously, and the electrical equipment is controlled by a programmable controller. The equipment is stable and reliable, and the operation is easy to learn.

| Model | DP-KT-5 |

| Wire diameter | Single wire: Rebar 5-12mm; Round wire 5-14mm |

| Double wire: Rebar 5-10mm; Round wire 5-10mm | |

| Max. pulling speed | 110M/min |

| Max. bending speed | 1000°/sec |

| Length tolerance | ±1mm |

| Bending tolerance | ±1° |

| Max. bending angle | ±180° |

| Max. length of the stirrup side (diagonal) | 1200mm(Can be customized) |

| Min. length of the stirrup side | 80mm |

| Production | 1800pcs/hour |

| Total power | 33kw |

| Note: Our factory also can produce a special size according to the client’s requirements | |

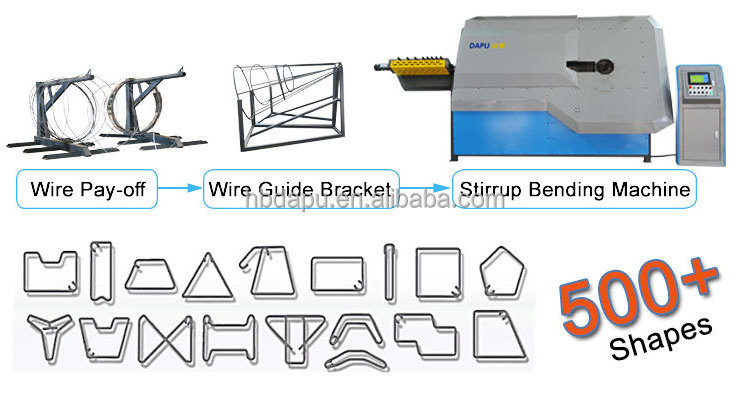

1. The pre-straightening mechanism adopts six sets of straightening wheels, so the straightening effect is better.

2. The traction gearbox structure: four traction wheels are made of high-hardness hard alloy materials, and the service life is longer.

3. The straightening mechanism adopts seven sets of straightening wheels and is perpendicular to the pre-straightening straightening wheels to prevent axial torsional deformation of the steel bar.

4. Mechanical cutter, faster cutting speed, and more accurate size.

5. The bending wheel can be rotated forward and backward quickly and retracted to ensure the bending accuracy of the steel bar.

6. The main shaft of the rotary splicer can be rotated 180°through gears, racks, and pneumatic components, which is convenient for splicing and retrieving.

7. Edit on the touch screen, which can store hundreds of graphics, easy to operate.

8. Auxiliary equipment: Wire pay-off + Wire guide bracket

Welcome to contact Alice for more details.