The prefabricated concrete formwork fixing magnetic box is a magnetic fixing device developed for fixing the prefabricated

concrete formwork. Compared with the traditional mechanical fixing methods such as screws and nuts, the magnetic box fixing has

the characteristics of half fast, flexible operation and good holding force, which is conducive to improving labor efficiency.

Therefore, it has been applied in the prefabricated concrete production line abroad.

When the magnetic box is in the working state, the suction surface at the bottom of the magnetic block is closely attached to the

precast concrete production platform for firm suction; When the lever is used to pry up the magnetic block, most of the magnetic

force is shielded by the magnetic box, and the magnetic force at the bottom is greatly reduced. The magnetic box can be easily

removed from the platform by hand.

- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Outdoor

-

Design Style:

-

Industrial

-

Type:

-

shuttering maget

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

JC

-

Model Number:

-

shuttering magnet

-

Product name:

-

shuttering magnet

-

Material:

-

Stainless Steel

-

Certificate:

-

ISO9001

-

Size:

-

500-2000KGS

-

Usage:

-

Concrete Construction Support

-

Color:

-

Customized

-

Packing:

-

Carton

-

Keywords:

-

shuttering magnet

-

Advantage:

-

Quick Assemble

-

Surface treatment:

-

OEM

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Online technical support, Onsite Installation, Onsite Training, Onsite Inspection, Free spare parts, Return and Replacement

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation

-

Application:

-

Outdoor

-

Design Style:

-

Industrial

-

Type:

-

shuttering maget

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

JC

-

Model Number:

-

shuttering magnet

-

Product name:

-

shuttering magnet

-

Material:

-

Stainless Steel

-

Certificate:

-

ISO9001

-

Size:

-

500-2000KGS

-

Usage:

-

Concrete Construction Support

-

Color:

-

Customized

-

Packing:

-

Carton

-

Keywords:

-

shuttering magnet

-

Advantage:

-

Quick Assemble

-

Surface treatment:

-

OEM

Basic Info.

|

|

|

|

Type

|

shuttering maget

|

|

Warranty

|

1 Year

|

|

After-sale Service

|

Online technical support, Onsite Installation, Onsite Training, Onsite Inspection, Free spare parts, Return and Replacement

|

|

Project Solution Capability

|

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation

|

|

Application

|

Outdoor

|

|

Design Style

|

Industrial

|

|

Place of Origin

|

China

|

|

|

Zhejiang

|

|

Brand Name

|

JC

|

|

Model Number

|

shuttering magnet

|

|

Product name

|

shuttering magnet

|

|

Material

|

Stainless Steel

|

|

Certificate

|

ISO9001

|

|

Size

|

500-2000KGS

|

|

Usage

|

Concrete Construction Support

|

|

Color

|

Customized

|

|

Packing

|

Carton

|

|

Keywords

|

shuttering magnet

|

|

Advantage

|

Quick Assemble

|

|

Surface treatment

|

OEM

|

Product Description

|

Product Name

|

500-2000KGS Formwork Shuttering Magnets Box

|

|

Compsite

|

Neodymium Magnet

|

|

Transport Package

|

Carton or Customized

|

|

Surface treatment

|

Customized

|

|

Application

|

Industrial Magnet, For Architecture Industry

|

|

Monthly Capacity

|

10000PCS

|

|

Shape

|

Sheet

|

|

Tolerance

|

±1%

|

|

Delivery Time

|

7-20days Depends on Quantities

|

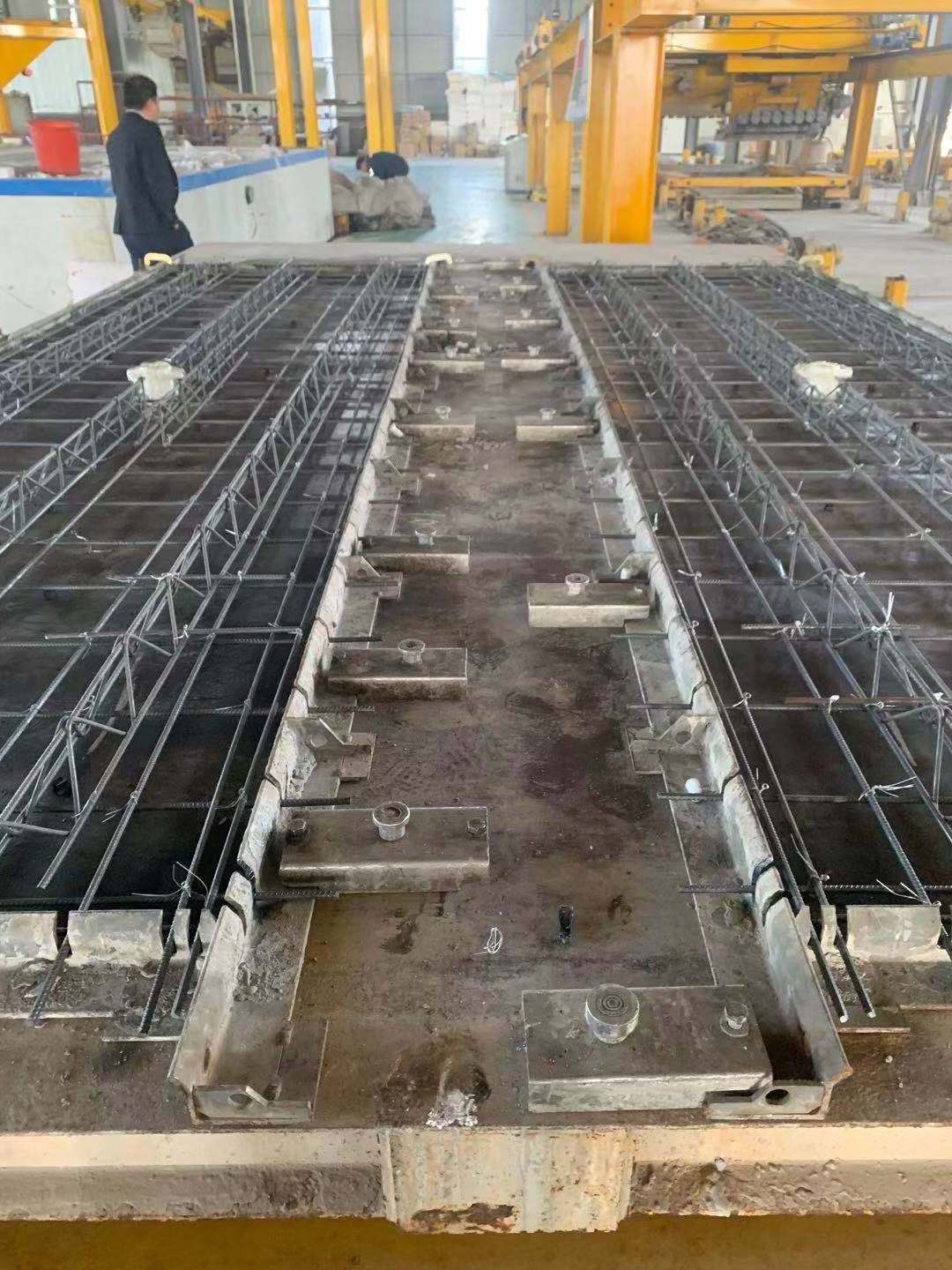

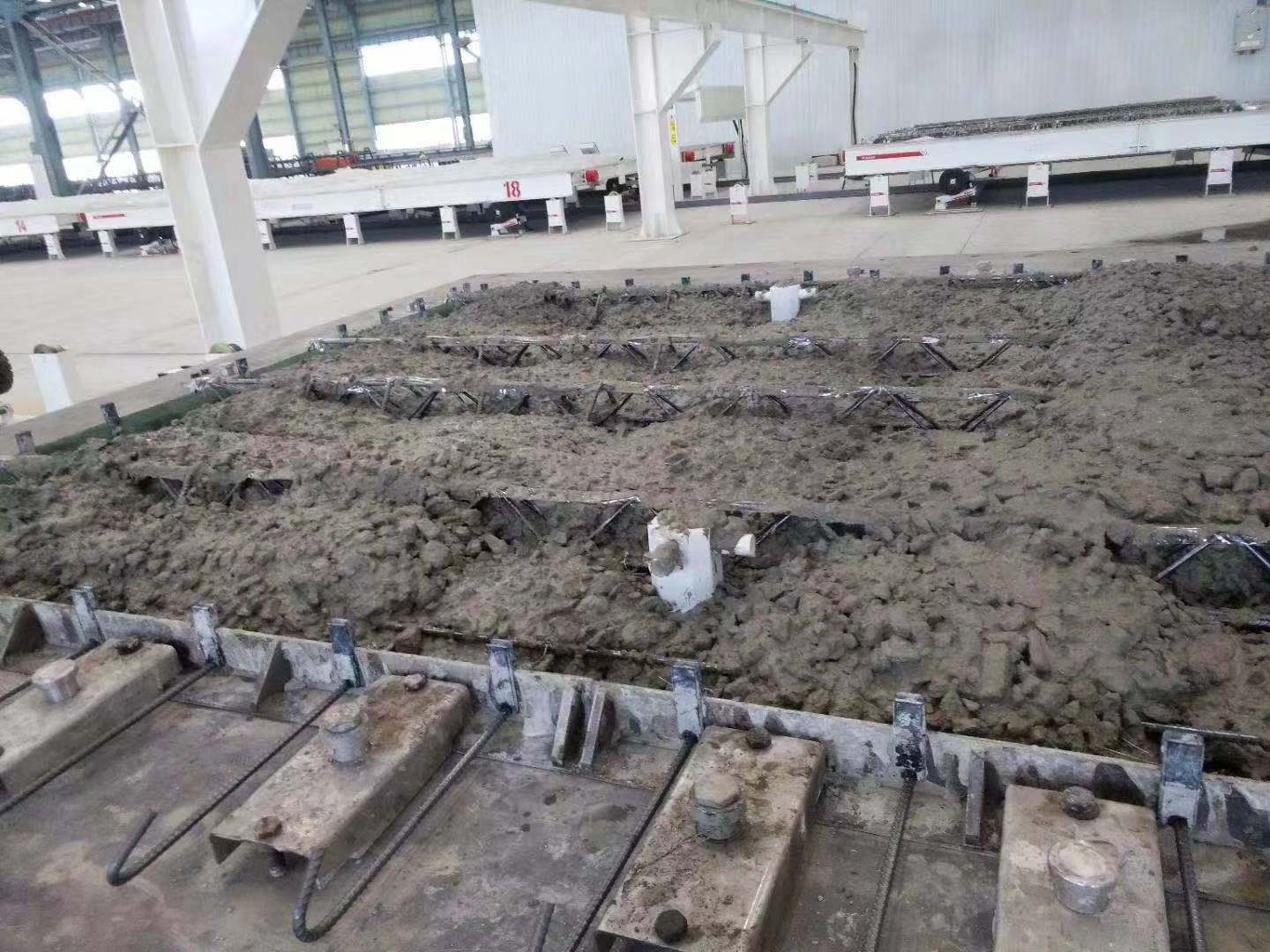

Application Scenario

Detailed Photos

Main uses and characteristics

usage method

(1) There is a magnetic control rod (magnetic control switch) on the shuttering magnet. Place shuttering magnet on the platform,

press the switch, and shuttering magnet will firmly absorb the platform and be in working state; When the lever is used to pry the

switch, the suction between shuttering magnet and the platform is greatly reduced, and shuttering magnet is closed, so shuttering

magnet can be moved.

(2) The thickness and surface flatness of the platform will affect the suction between shuttering magnet and the platform. The

thicker the platform, the smoother the surface, the greater the suction, and the lateral shear force is related to the suction of

shuttering magnet and the friction coefficient of the contact surface.

(3) There are two fixing screws at both ends of shuttering magnet , which can be connected with different fixtures to fix side

molds with different shapes and structures, such as angle steel, channel steel side molds, etc.

(4) shuttering magnet uses strong magnetism. Theoretically, the magnetic force can be maintained on the premise of not exceeding

the working temperature and not damaging the rusted magnet itself.

(5)Environmental conditions for the use of shuttering magnet : 1. The ambient temperature shall not be greater than 80 ºC. 2. The

surrounding medium shall be free of corrosive agents that corrode metals.

press the switch, and shuttering magnet will firmly absorb the platform and be in working state; When the lever is used to pry the

switch, the suction between shuttering magnet and the platform is greatly reduced, and shuttering magnet is closed, so shuttering

magnet can be moved.

(2) The thickness and surface flatness of the platform will affect the suction between shuttering magnet and the platform. The

thicker the platform, the smoother the surface, the greater the suction, and the lateral shear force is related to the suction of

shuttering magnet and the friction coefficient of the contact surface.

(3) There are two fixing screws at both ends of shuttering magnet , which can be connected with different fixtures to fix side

molds with different shapes and structures, such as angle steel, channel steel side molds, etc.

(4) shuttering magnet uses strong magnetism. Theoretically, the magnetic force can be maintained on the premise of not exceeding

the working temperature and not damaging the rusted magnet itself.

(5)Environmental conditions for the use of shuttering magnet : 1. The ambient temperature shall not be greater than 80 ºC. 2. The

surrounding medium shall be free of corrosive agents that corrode metals.

Maintenance and instructions

(1) During the use of the magnetic box, the deformation of the magnetic control box and even the damage of the magnet caused by

knocking and bumping with hard tools shall be prevented, so as not to affect the service performance. If tools are to be used, it

is recommended to tap gently with a rubber hammer.

(2) The platform for using the magnetic box shall be kept clean and flat to prevent iron filings or concrete slurry from entering

the magnetic box, which will affect the flexibility of the switch. At the same time, it may cause the magnetic block to tilt and

cannot fit the platform smoothly, so as to weaken the working suction.

(3) The magnetic box shall not be close to instruments, electronic instruments and other devices vulnerable to magnetic force. At

the same time, it shall not be close to other ferrous materials. Once adsorbed, it will be difficult to separate. It is

recommended to place the magnetic box and other magnetic holders in the toolbox.

(4) The holding surface of the magnetic box shall be kept clean and flat. If it is not used for a long time, the holding surface

shall be oiled for rust prevention. Frequently check whether the magnetic block can fit the platform smoothly and whether the

switch is flexible without affecting the normal use.

knocking and bumping with hard tools shall be prevented, so as not to affect the service performance. If tools are to be used, it

is recommended to tap gently with a rubber hammer.

(2) The platform for using the magnetic box shall be kept clean and flat to prevent iron filings or concrete slurry from entering

the magnetic box, which will affect the flexibility of the switch. At the same time, it may cause the magnetic block to tilt and

cannot fit the platform smoothly, so as to weaken the working suction.

(3) The magnetic box shall not be close to instruments, electronic instruments and other devices vulnerable to magnetic force. At

the same time, it shall not be close to other ferrous materials. Once adsorbed, it will be difficult to separate. It is

recommended to place the magnetic box and other magnetic holders in the toolbox.

(4) The holding surface of the magnetic box shall be kept clean and flat. If it is not used for a long time, the holding surface

shall be oiled for rust prevention. Frequently check whether the magnetic block can fit the platform smoothly and whether the

switch is flexible without affecting the normal use.

Exhibition

Hot Searches