- Product Details

- {{item.text}}

Quick Details

-

Name:

-

Rock Gold Separation process plan

-

Voltage:

-

220v 380v 440v

-

Capactity:

-

50TPD,100TPD,200TPD or above

-

Power:

-

2.2kw

-

Slurry water(L/min):

-

15

-

Application:

-

Gold

-

Installation:

-

Engineer Guide

-

Usage:

-

Mining Concentration

-

After sale service:

-

Provide Engineer Service Overseas

Quick Details

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

DESEN MINING

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Overseas service center available

-

Name:

-

Rock Gold Separation process plan

-

Voltage:

-

220v 380v 440v

-

Capactity:

-

50TPD,100TPD,200TPD or above

-

Power:

-

2.2kw

-

Slurry water(L/min):

-

15

-

Application:

-

Gold

-

Installation:

-

Engineer Guide

-

Usage:

-

Mining Concentration

-

After sale service:

-

Provide Engineer Service Overseas

Product Description

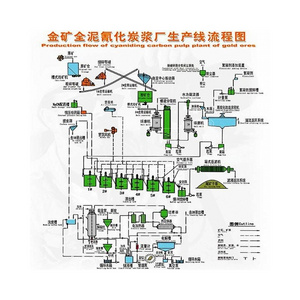

Rock Gold CIP/CIL Plant

Carbon-in-pulp (CIP)

is the sequential leach then absorption of gold from ore. During the CIP stage, pulp flows through several agitated tanks where sodium cyanide and oxygen have been added to dissolve gold into solution. In the absorption stage, this solution flows through several agitated tanks containing activated carbon. Gold absorbs onto the activated carbon, which flowscountercurrent to the pulp, while screens separate the barren pulp from the gold-loaded carbon.

Carbon-in leach (CIL) is a simultaneous leach and absorption process. The simultaneous leach and absorption phases of the CIL process were developed for processing gold ores that contain preg-robbing materials such as natural absorptive carbon. These reduce the gold yield by attracting gold meant for the activated carbon. Simultaneous leaching and absorption help minimize the problem.

Carbon-in leach (CIL) is a simultaneous leach and absorption process. The simultaneous leach and absorption phases of the CIL process were developed for processing gold ores that contain preg-robbing materials such as natural absorptive carbon. These reduce the gold yield by attracting gold meant for the activated carbon. Simultaneous leaching and absorption help minimize the problem.

ADVANTAGE:

1. Mature Cyanidation Leaching Flow

1. Mature Cyanidation Leaching Flow

(Over 20 years experience on this field and done many projects oversea).

2. Cost Control

2. Cost Control

(Have lots of site experience, from equipments, installation to personnel site working, we can make a most optimal case to you).

3. EPC-Turkey Project

(We have enough capability to make EPC-Turkey project, which will be convenient for you).

3. EPC-Turkey Project

(We have enough capability to make EPC-Turkey project, which will be convenient for you).

Crushing and Grinding system

In Gold CIP/CIL plant, to achieve high recovery rate, usually adopts double ball mill, one is grid type, one is overflowed type,the grinding size will be 90%-200 mesh.

In Gold CIP/CIL plant, to achieve high recovery rate, usually adopts double ball mill, one is grid type, one is overflowed type,the grinding size will be 90%-200 mesh.

Thickening Syetem

After ball mill grinding, the ore pulp will be feed into thickner to dewater to achieve proper density to go next step leaching.Under the thickner, there is enough space to build several warehouse and install a chemical mix tank.

Leaching System

After the ore pulp adding cyanide, it will be pumped to leaching tank, usually we adopts 8 leaching tanks, installed in stair-stepping, the toppest two is preleaching tank, will add actived carbon from lowest one, then use carbon lifting pump and carbon screen to lift the gold carried carbon one by one till highest.

After leaching, gold mud in grade about 30-40% will feed into electrolysis machine or melting furnace to separate gold and carbon,after this step, the carbon can be recycled by acid and water washing tank. At last the gold grade will be at 98% above.

After leaching, gold mud in grade about 30-40% will feed into electrolysis machine or melting furnace to separate gold and carbon,after this step, the carbon can be recycled by acid and water washing tank. At last the gold grade will be at 98% above.

Detailed Images

Best Selling

Company Introduction

We are a professional manufacturer of various kinds of mining equipments in China for over 20 years, especially have rich

experience at mining separating, main products include:

shaking table

gold centrifugal concentrator

gold washing trommel screen

small scale mobile gold washing trommel screen

jig machine

spiral chute separator

>>Our alibaba homepage

experience at mining separating, main products include:

shaking table

gold centrifugal concentrator

gold washing trommel screen

small scale mobile gold washing trommel screen

jig machine

spiral chute separator

>>Our alibaba homepage

Our Services & Strength

Pre-sale services

We will provide you with the prior plan, process flow design and production equipment in line with your special needs.

Sale services

We will send technicians to you for guiding the equipment installation and commissioning and staff training.

After-sale services: faithfulness

We will regularly return visit to customers for establishing a long-term and friendly relationship.

We will provide you with the prior plan, process flow design and production equipment in line with your special needs.

Sale services

We will send technicians to you for guiding the equipment installation and commissioning and staff training.

After-sale services: faithfulness

We will regularly return visit to customers for establishing a long-term and friendly relationship.

FAQ

Q: Before you design the flow, what should I let you know?

A: 1. Raw ore information(analysis report or pics).

2. Capacity.

If you need, we can make the test for you.

After knowing above, we can design the customized flow for you.

A: 1. Raw ore information(analysis report or pics).

2. Capacity.

If you need, we can make the test for you.

After knowing above, we can design the customized flow for you.

Hot Searches