- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

SDCAD

-

Motor Power:

-

30~110kw

-

Charging Capacity:

-

50L~3000L

-

Reclaiming capacity:

-

50L~3000L

-

Speed of Mixing Drum:

-

35r/min

-

Water Supply Mode:

-

Automatic Pump

-

Working Cycle Period:

-

≤45s

-

Discharge Way:

-

Hydraulic Discharging;Manual

-

Outline Dimension:

-

3900*3600*3100mm

-

Warranty of core components:

-

2Year

-

Weight (KG):

-

800 kg

-

Power type:

-

Electric Motor

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Application:

-

glass industry ,ceramic industry ,concrete industry

-

Concrete mixer type:

-

Planetrary Mixer

-

Capacity:

-

50L-3000L

-

Advantage:

-

High Mixing Efficiency

-

Feature:

-

Automatic Loading

-

Control Method:

-

Electric Control Cabinet

-

After Warranty Service:

-

Engineers available to service machinery overseas

-

Function:

-

Mixing Sand Stone

Quick Details

-

Mixing Power:

-

30~110kw

-

Productivity:

-

5~180 m3/h

-

Place of Origin:

-

China

-

Brand Name:

-

SDCAD

-

Motor Power:

-

30~110kw

-

Charging Capacity:

-

50L~3000L

-

Reclaiming capacity:

-

50L~3000L

-

Speed of Mixing Drum:

-

35r/min

-

Water Supply Mode:

-

Automatic Pump

-

Working Cycle Period:

-

≤45s

-

Discharge Way:

-

Hydraulic Discharging;Manual

-

Outline Dimension:

-

3900*3600*3100mm

-

Warranty of core components:

-

2Year

-

Weight (KG):

-

800 kg

-

Power type:

-

Electric Motor

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Application:

-

glass industry ,ceramic industry ,concrete industry

-

Concrete mixer type:

-

Planetrary Mixer

-

Capacity:

-

50L-3000L

-

Advantage:

-

High Mixing Efficiency

-

Feature:

-

Automatic Loading

-

Control Method:

-

Electric Control Cabinet

-

After Warranty Service:

-

Engineers available to service machinery overseas

-

Function:

-

Mixing Sand Stone

Product Overview

Planetary Concrete Mixer

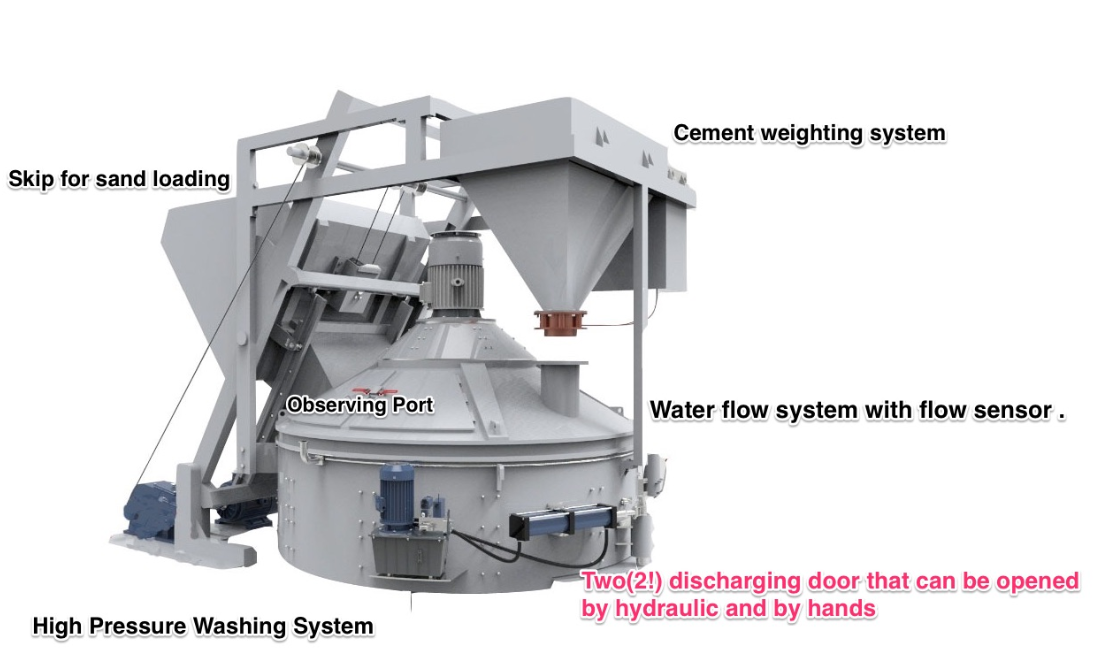

MP series planetary concrete mixer used for mixing concrete .It is not only applies in common concrete ,precast concrete but also in high performance concrete. Planetary Concrete Mixers widely apply to produce precast concrete, common commercial concrete and high performance concrete.

It is suitable for mixing dry hard concrete (roller compacted concrete). It is widely used in the production of building blocks and prefabricated parts, and also can be used to produce of steel fiber reinforced concrete, color concrete and dry mortar, etc.

We also could

customize observing door, skip hopper, extended funnel

with bag breaker for

bag

,

cement weighting device

and

water metering device

according to

customers' requirement.

FEATURES AT A GLANCE

Our Advantage

Customized service:

Unique top opening design.Position and size of the feeding inlet according to the customer's needs.

Capacity :

50L~1500L

♦Durable chill cast wear sleeves and paddles

♦Hard wearing chill cast tiles for wall and floor

♦Heavy duty discharge door mechanisms

♦Spring tensioned mixing arms for safety

♦Motor and gearbox are located on top of the mixer for easy cleaning and maintenance

♦Hard wearing chill cast tiles for wall and floor

♦Heavy duty discharge door mechanisms

♦Spring tensioned mixing arms for safety

♦Motor and gearbox are located on top of the mixer for easy cleaning and maintenance

Full Process Solution Provider of SDCADI

MP50

MP250

MP500

MP750

MP1000

MP2000

SDCADI Planetary Mixer Features

* Optimum Homogenization of mixing materials.

* Adopt special high-strength, high-reliability planetary reducer with patent.

* Simple Structure, Simple and Convenient Maintenance.

* Flexible Layout, 1-3 unloading doors are optional for different production lines.

* Dustproof movable covers assisted by gas springs.

* Interlocking device and safety switch on every movable cover.

* Interchangeable wear-resistant liners with counter sunk fixing bolts.

* All on-board engineering is protected in PVC-coated metal conduits and connected to a heavy-duty aluminum junction box.

* Optimum Homogenization of mixing materials.

* Adopt special high-strength, high-reliability planetary reducer with patent.

* Simple Structure, Simple and Convenient Maintenance.

* Flexible Layout, 1-3 unloading doors are optional for different production lines.

* Dustproof movable covers assisted by gas springs.

* Interlocking device and safety switch on every movable cover.

* Interchangeable wear-resistant liners with counter sunk fixing bolts.

* All on-board engineering is protected in PVC-coated metal conduits and connected to a heavy-duty aluminum junction box.

PRODUCT CONFIGURATION

Mixing Locus Diagrams

This diagrams show the perfect mixing action of the DEX planetary mixer from 5 to 60 seconds after material is added. Note that the floor is completely swept by the mixing stars action every 4 revolutions (6 seconds) and that each zone is covered at regular intervals in time.

Reduction Gearbox

The gearbox unit, specially designed for a balanced distribution of power to the various mixing device ensures a high efficiency and low-noise rotation.

Maintenance Access

Large access facility is for easy maintenance and cleaning The key operated safety switch guarantees the motor cannot be powered with cover open.

Mixing Device

Special designed mixing facility make the mixing faster and more homogeneous, no material heaped.

The hydraulic power unit

Specially designed to meet the requirement for more discharge gates and manual unloading device in case of emergency is installed,you can manually open the discharge gate.

Hydraulic Unit

Hydraulic unit equipped with manual pump allows the door be opened in case of electric failure.

Hydraulic unit equipped with manual pump allows the door be opened in case of electric failure.

Water spray pipe

The special designed sprayer is installed on the water pipe. The spraying water cloud can cover more area and also make the mixing more homogeneous.

Mixing Pan with Wear Linings

SDCADI Planetary mixer is meticulously engineered with high-strength structural steel and durable wear-resistant lining plates.Our planetary mixer achieves a stringent control of the roundness and flatness error of the mixing drum, ensuring a maximum deviation of only 2-3mm for pristine discharge.

The lining plates of our planetary mixer are carefully selected to cater to the specific mixing requirements of diverse raw materials. These include high-chromium alloy cast, hardox steel, PE polymer,

surfacing, stainless steel, and other suitable options, depending on the specific raw materials to be mixed.

surfacing, stainless steel, and other suitable options, depending on the specific raw materials to be mixed.

PRODUCT SPECIFICATIONS

|

Model

|

MP330

|

MP500

|

MP750

|

MP1000

|

MP1500

|

MP2000

|

MP2500

|

MP3000

|

|

Output Capacity (L)

|

330

|

500

|

750

|

1000

|

1500

|

2000

|

2500

|

3000

|

|

Input Capacity (L)

|

500

|

750

|

1125

|

1500

|

2250

|

3000

|

3750

|

4500

|

|

Input Mass (kg)

|

800

|

1200

|

1800

|

2400

|

3600

|

4800

|

6000

|

7200

|

|

Mixing Power (kw)

|

15

|

18.5

|

30

|

37

|

55

|

75

|

90

|

110

|

|

Discharge Power (kw)

|

2.2

|

2.2

|

2.2

|

3

|

3

|

4

|

4

|

4

|

|

Lifting Power (kw)

|

4

|

4

|

7.5

|

11

|

15

|

22

|

--

|

--

|

|

Skipper Capacity (L)

|

580

|

870

|

1300

|

1740

|

2610

|

3480

|

--

|

--

|

|

Skipper Mass (kg)

|

870

|

1305

|

1950

|

2610

|

3615

|

5220

|

--

|

--

|

|

Skipper Speed (m/s)

|

0.25

|

0.25

|

0.25

|

0.25

|

0.25

|

0.25

|

--

|

--

|

|

Weight (kg)

|

1700

|

2000

|

3500

|

6000

|

7000

|

8500

|

10500

|

11000

|

|

Dimension (mm)

|

1910 * 1590* 1747

|

2220* 2071* 1880

|

2581* 2336 * 2195

|

2891* 2602* 2217

|

3223* 2902* 2425

|

3625*3230* 2630

|

2893* 3550* 2695

|

3893* 3550* 2975

|

Packaging and Transportation

Our Services

1.According to your inquiry, We will reply to you in 24 hours.

2.Best After-sales: We will send the technical personnel to the site for installation, commissioning and training work.

3.Warranty period 12 Months, in addition to the force majeure and man-made factors, the damage caused by design, process and manufacturing equipment, the seller is responsible for sending people to offer free repair.

4.We will send the spare parts as soon as possible when necessary, equipment repair parts provided by the seller are original,authentic, quality goods.

2.Best After-sales: We will send the technical personnel to the site for installation, commissioning and training work.

3.Warranty period 12 Months, in addition to the force majeure and man-made factors, the damage caused by design, process and manufacturing equipment, the seller is responsible for sending people to offer free repair.

4.We will send the spare parts as soon as possible when necessary, equipment repair parts provided by the seller are original,authentic, quality goods.

Industry Application

Concrete pipe

Sleeper

Concrete block

Refratory

Refractory castable

Glass

Successful Project

Project in

Italy

Project in

Romania

Project in

Mexico

Project in

New Zealand

Project in India

Project in Russia

SALES AND SERVICE NETWORK

SIMILAR PRODUCTS

Twin shaft concrete mixer

Concrete batching plant

Storage silo

Asphalt mixing plant

Motar mixing plant

Screw conveyor

FAQ

Are you a manufacturer or Trader?

What is your delivery time?

We are a professional manufacture , we have our own R&D team and sales team, we provide one-stop

service.

service.

What is your payment term?

We accept T/T, L/C at sight, Western Union, Paypal etc.

How long is the validity of quotation?

Generally, our price is valid within one month from the date of quotation . The price will be adjusted appropriately according to the price fluctuation of raw materials and changes in market .

Generally, our price is valid within one month from the date of quotation . The price will be adjusted appropriately according to the price fluctuation of raw materials and changes in market .

Usually, we make merchandise inventory, if we have the products in stock, the delivery time is 5-10

days after receiving the deposit. If we don't have the products in stock, we will arrange the production right now, the delivery time will be 10-30 days,It depend on the order quantity.

days after receiving the deposit. If we don't have the products in stock, we will arrange the production right now, the delivery time will be 10-30 days,It depend on the order quantity.

Do you provide OEM/ODM Service?

Yes, offer me necessary information, we provide custom-make service to meet different needs of global clients with different budgets.

How can we ensure quality?

The final inspection is always carried out before shipment. How to install the equipment after purchasing? We will provide a professional installation video to illustrate.Also provide a manual.

Do you offer a guarantee?

The final inspection is always carried out before shipment. How to install the equipment after purchasing? We will provide a professional installation video to illustrate.Also provide a manual.

Do you offer a guarantee?

Yes, we guarantee our product for one year. Provide after-sales service support with and agricultural

technical support.

technical support.

What is your MOQ?

1Sets

Hot Searches