- Product Details

- {{item.text}}

Quick Details

-

Usage:

-

Animal Poultry Livestock Pellet Making Machine

-

Function:

-

Aniaml Feed Puffed Pellet Machine

-

Color:

-

Clients' Requirement

-

Material:

-

Durable Carbon Steel

-

Advantage:

-

High Capacity

-

Raw material:

-

Soybean Meal

-

Brand:

-

Chengzhu

-

Certification:

-

ISO9001

Quick Details

-

Place of Origin:

-

Hebei, China

-

After-sales Service Provided:

-

Field installation, commissioning and training, Field maintenance and repair service

-

Name:

-

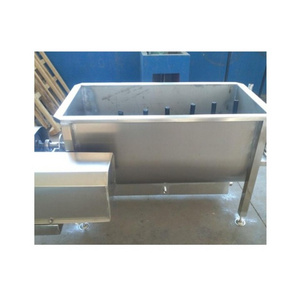

Large Quantity Chicken Meal Chicken Oil Cooker for chicken farm

-

Usage:

-

Animal Poultry Livestock Pellet Making Machine

-

Function:

-

Aniaml Feed Puffed Pellet Machine

-

Color:

-

Clients' Requirement

-

Material:

-

Durable Carbon Steel

-

Advantage:

-

High Capacity

-

Raw material:

-

Soybean Meal

-

Brand:

-

Chengzhu

-

Certification:

-

ISO9001

Poultry equipment poultry slaughtering carcass processing equipment fish processing equipment

The whole line were consists of material buffer bin, conveyor, cooker dryer ,grinding ,packing and odor treatment system.

1.poultry waste reception section

1, The material silo

Function: for the reception and storage of poultry waste,dead animal.

2, The middle is pre-crushing machine

Function:for chopping of whole animal carcasses and large pieces with aim of 50mm size pieces(easily transported)

3, The botton is a material pump.

Function:transport the material to cooker.

2. Cooker and dryer section

Fuction: Waste of raw material (feathers,animal fur,sick livestock,animal carcasses)through tghe process of high temperature and pressure to achieve the effect of sterilization and break down.

Features:Big capacity of each batch,the efficiency of sterilization is completely and safe. It has the fuction of break, cook, sterilization and drying.

3. Meal section

Fuction:To reduce the size of meal .

Features:1.Unique crushing chamber to improve the grinding efficiency.

2.Special rotor desgn program, and the hammer sieve gap, which can meet different granularity.

4.Packing section

Automatic paking the meal

5. Odor treatment section

To seperate solids and liquids entrained in the process vapoures from cooking/drying equipment, by washing of gasses collected from several process points.

Final products:

If you need more information, please contact us

We can customize for you of the right solution, according to your needs.

Process Flow:

Crusher ----> Cooker ----> Dryer ----> Defatting ----> Cooling ----> Milling ----> Packing

Notes:

We can design a turnkey production line for our customers,the line including many machines,customer also can choose the one they need depend on their production and the founds,so no matter what requriements you have,we will try our best to meet with you

Pre-sale Service:

Your inquiry related to equipment or price will be replied within 24 hours.

Well-trained and experienced staff will answer all your inquiries in English of course.

We accept OEM&ODM projects.

We have strong R&D team here to help.

Your business relationship will be confidentional to any third party

After-sale Service:

1 year warranty period, please don't hesitate to contact us if you have any question with the equipment