- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V 380V 410V

-

Dimension(L*W*H):

-

46m*6m*3.6m

-

Power (kW):

-

96

-

Weight:

-

2000

-

Screw Speed (rpm):

-

60 - 65 rpm

-

Function:

-

Plastic Rcycling

-

Local Service Location:

-

Turkey

-

After Warranty Service:

-

No service

-

Machine Type:

-

Single Stage Pelletizing

-

Marketing Type:

-

New Product 2020

-

Application:

-

Granules Production

-

Raw material:

-

PP PE Film Bags Material

-

Final product:

-

Small Plastic Pellet

-

Material Processed:

-

Compacting ---pelletizer---cutting ---drying

Quick Details

-

Output (kg/h):

-

100 - 1000 kg/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

+86 15376997983

-

Voltage:

-

220V 380V 410V

-

Dimension(L*W*H):

-

46m*6m*3.6m

-

Power (kW):

-

96

-

Weight:

-

2000

-

Screw Speed (rpm):

-

60 - 65 rpm

-

Function:

-

Plastic Rcycling

-

Local Service Location:

-

Turkey

-

After Warranty Service:

-

No service

-

Machine Type:

-

Single Stage Pelletizing

-

Marketing Type:

-

New Product 2020

-

Application:

-

Granules Production

-

Raw material:

-

PP PE Film Bags Material

-

Final product:

-

Small Plastic Pellet

-

Material Processed:

-

Compacting ---pelletizer---cutting ---drying

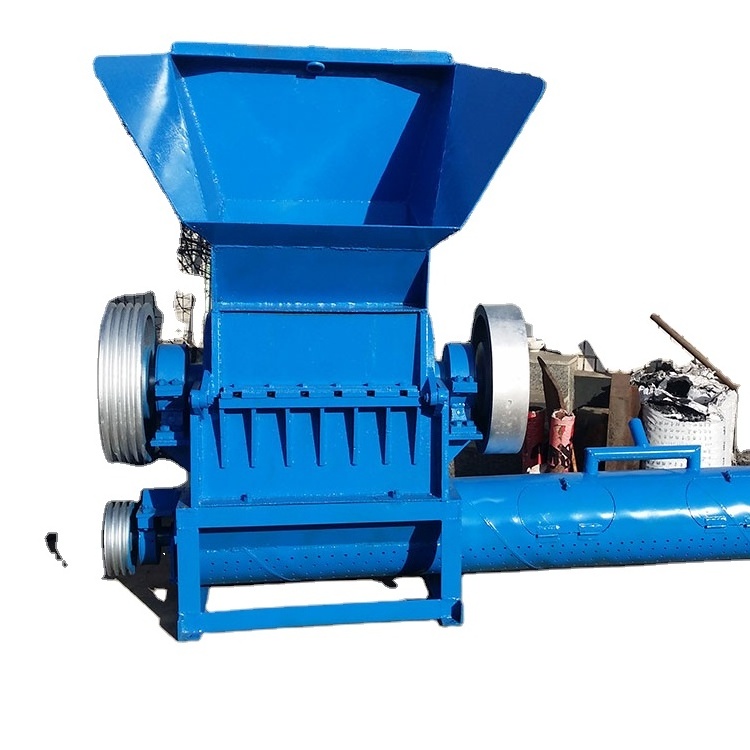

Product Description

1. The whole production line is mainly designed for a large number of recycled PP/PE/PVC film, agricultural film, plastic film, packaging film, and a large number of convenient bags, vest bags, handbags, shopping bags, as well as cement bags, woven bags, snake skin bags, grain bags, fertilizer bags, jumbo bags, and other soft waste plastic broken cleaning and drying. Coordination with the follow-up process (granulation system) of the production line, which will make garbage film and dirty PE / PP film, PP woven bag is PE / PP film, PP woven bag particulate matter, used to produce new PE, PP film, etc.

2. the entire production line is fully automatic control, compact layout and high production efficiency.

3. Because it is an open combined equipment, different cleaning schemes, cleaning processes, recovery planning and site

planning can be designed according to the actual situation of users.

4. The equipment is widely used in recycling and processing enterprises which have a certain scale and pursue automation benefits, such as: recycled particles of large and medium-sized cement bags; recycling and granulating of PP and PE films; crushing and cleaning of waste plastic and plastic film materials in large paper mills and garbage dumps.

5. Capacity: 100KG/H-1000KG/H

6. Size of final product can be adjusted according to change crusher screen mesh.

2. the entire production line is fully automatic control, compact layout and high production efficiency.

3. Because it is an open combined equipment, different cleaning schemes, cleaning processes, recovery planning and site

planning can be designed according to the actual situation of users.

4. The equipment is widely used in recycling and processing enterprises which have a certain scale and pursue automation benefits, such as: recycled particles of large and medium-sized cement bags; recycling and granulating of PP and PE films; crushing and cleaning of waste plastic and plastic film materials in large paper mills and garbage dumps.

5. Capacity: 100KG/H-1000KG/H

6. Size of final product can be adjusted according to change crusher screen mesh.

fully automatic pp hd recycling machine

Specification

|

Main Drive Power

|

18.5kw

|

30kw

|

45kw

|

55kw

|

75kw

|

90kw

|

|

Spindle Speed

|

720rpm

|

680rpm

|

680rpm

|

680rpm

|

600rpm

|

600rpm

|

|

Swing Diameter

|

400mm

|

450mm

|

600mm

|

700mm

|

850mm

|

1100mm

|

|

Blade Length

|

500mm

|

600mm

|

800mm

|

1000mm

|

1200mm

|

1500mm

|

|

Dimensions (approx.)

|

1210X1370X1450mm

|

1370X1590X1660mm

|

1620X1840X1890mm

|

1880X1990X2100mm

|

2370X2300X2460mm

|

2790X2590X2650mm

|

|

Weight (approx.)

|

1200kg

|

2100kg

|

2800kg

|

3700kg

|

4900kg

|

6000kg

|

|

Body width (mm)

|

500

|

600

|

800

|

1000

|

1200

|

|

Rotation diameter (mm)

|

400

|

450

|

550

|

600

|

700

|

|

Spindle speed N(r/min)

|

700

|

700

|

700

|

650

|

650

|

|

Spindle drive power P (kg)

|

18.5

|

22

|

30

|

45

|

55

|

|

Total number of tools T(B)

|

5

|

8

|

10

|

10

|

13

|

|

Length of washing barrel (mm)

|

2500

|

3000

|

3300

|

4000

|

4300

|

|

Washing drive power (kw)

|

7.5

|

7.5

|

11

|

15

|

18.5

|

|

Total Weight (kg)

|

1400

|

2000

|

2600

|

4000

|

7300

|

|

Production capacity Q(kg/h)

|

300-350

|

300-450

|

500-600

|

700-1000

|

1200-1500

|

|

Capacity(kg/h)

|

Power consumption (kw)

|

Water consumption (ton/h)

|

Manpower

|

Humidity Content

|

|

300kg/hour

|

125kw

|

3ton/h

|

3

|

≤5%

|

|

500kg/hour

|

260kw

|

4-5ton/h

|

3

|

≤5%

|

|

700kg/hour

|

450kw

|

5ton/h

|

4

|

≤5%

|

|

1000kg/hour

|

395kw

|

6ton/h

|

4

|

≤5%

|

|

1600kg/hour

|

960KW

|

8ton/h

|

6

|

≤5%

|

Our Advantages

Advantages

1. Final products has good quality. When process PP PE film bags, final products humidity below 5%.

2. The machine with high efficiency, working stable, large capacity etc.

3. Parts which contact material use SUS304, thickness more than 3mm, ensure long service life time.

4. World famous brand components applied on the production line- SKF bearing, Siemens contactor, Japan RKC temperature, ABB invertor, Siemens PLC control.

1. Final products has good quality. When process PP PE film bags, final products humidity below 5%.

2. The machine with high efficiency, working stable, large capacity etc.

3. Parts which contact material use SUS304, thickness more than 3mm, ensure long service life time.

4. World famous brand components applied on the production line- SKF bearing, Siemens contactor, Japan RKC temperature, ABB invertor, Siemens PLC control.

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Hot Searches