- Product Details

- {{item.text}}

Quick Details

-

Table Travel (Z) (mm):

-

50

-

Cutting Accuracy(mm):

-

±0.05

-

Brand Name:

-

Forplus

-

Voltage:

-

220V

-

Rated Power:

-

50HZ

-

Dimension(L*W*H):

-

1000*1000*1090

-

Weight (KG):

-

120 KG

-

Applicable Industries:

-

Roads,railways, and tunnels, Mining, petroleum extraction, aerospace, and ships, robotic automation, Demonstration, testing, teaching scenarios

-

Type:

-

Mini portable

-

Advantage1:

-

High Efficiency Low Cost

-

Advantage2:

-

Long Worklife

-

CNC System & Software:

-

Configure any laptop

Quick Details

-

Place of Origin:

-

Liaoning, China

-

Table Travel (X) (mm):

-

500

-

Table Travel (Y) (mm):

-

500

-

Table Travel (Z) (mm):

-

50

-

Cutting Accuracy(mm):

-

±0.05

-

Brand Name:

-

Forplus

-

Voltage:

-

220V

-

Rated Power:

-

50HZ

-

Dimension(L*W*H):

-

1000*1000*1090

-

Weight (KG):

-

120 KG

-

Applicable Industries:

-

Roads,railways, and tunnels, Mining, petroleum extraction, aerospace, and ships, robotic automation, Demonstration, testing, teaching scenarios

-

Type:

-

Mini portable

-

Advantage1:

-

High Efficiency Low Cost

-

Advantage2:

-

Long Worklife

-

CNC System & Software:

-

Configure any laptop

Products Description

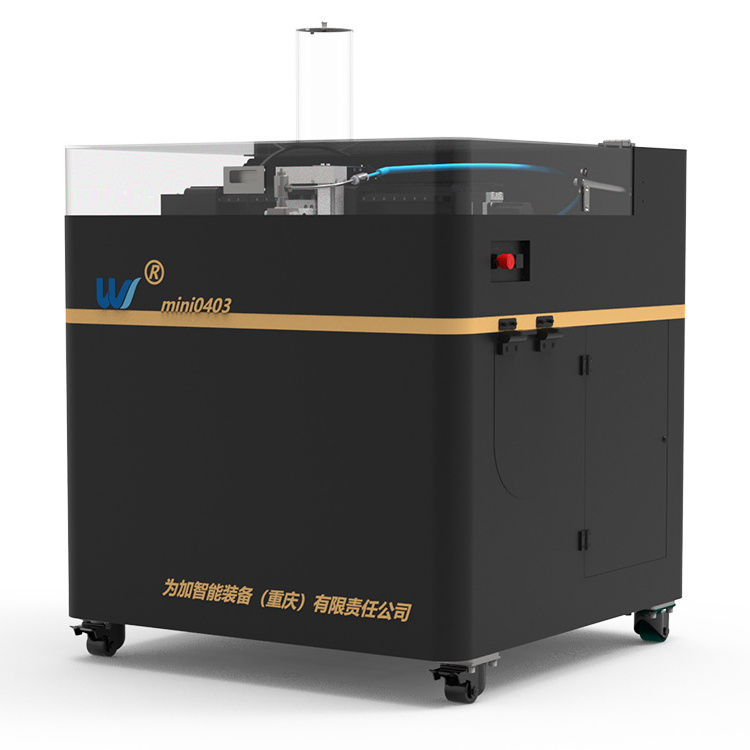

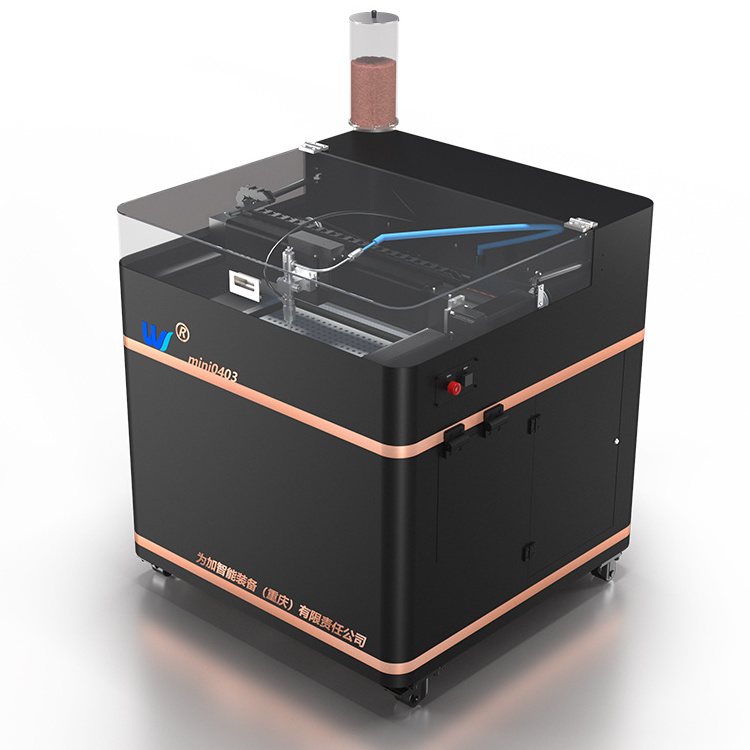

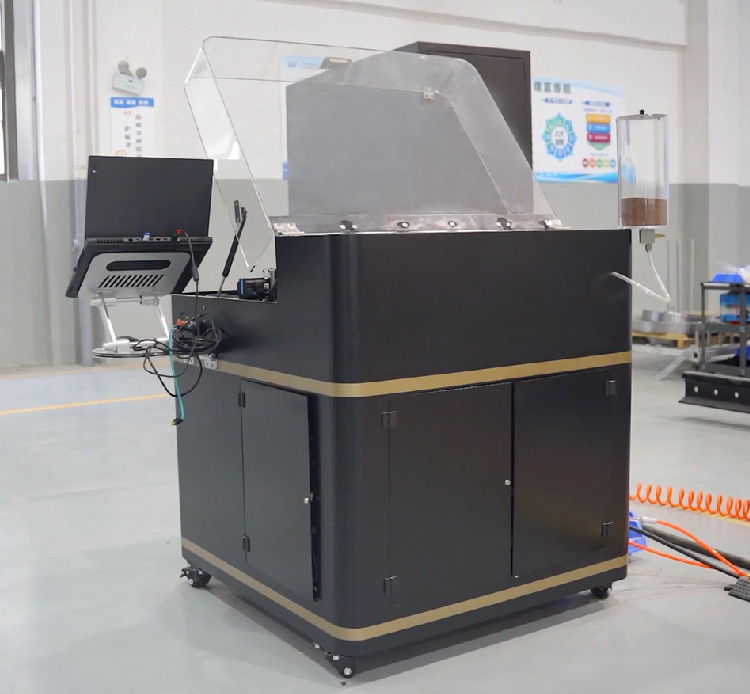

Forplus Mini portable water jet cutting machine

is a new portable mobile water jet cutting integration machine self developed by Forplus company.This machine can be fastly operated with conventional 220V AC current and 30000 psi (200 Mpa) high pressure, and it can easily realize fine cutting for unlimited materials with small size and low thickness. With wheels underneath, Forplus Mini portable machine can move easily. 360°fully closed, with an acrylic transparent visible top cover, it's easy to observe the inside cutting status. It is widely used in research, teaching, testing applications and other low-frequency small-scale high-pressure water jet applications. Forplus mini portable high pressure water jet cutting machine belongs to cold cutting,no thermal effect for structure,with smooth cutting surface,no need secondary processing,and with powerful capability of advanced water system and also high cost performance.

No need installation,easy commissioning.

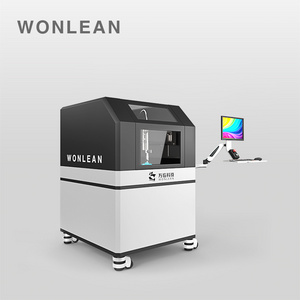

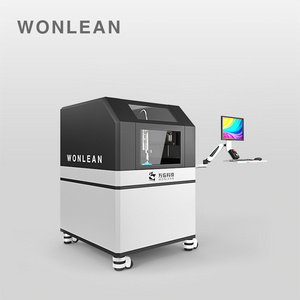

Professional XL CNC water cutting software communicating with any laptop,can control operation by connecting dongle.

Lead-in DXF file,automatically typeset and generate cutting track. Simple operation,multiple customized cutting logic,suitable for different cutting scenarios.

Details Images

Fully enclosed

transparent top cover

Safe,tidy,and easy to observe.

Configure standard 3-axis cutting head

Gem and nozzle can be flexibly changed, simultaneously pure water cuting and abrasive cuting.

Well-known brand high quality electrical components are used for the whole machine to ensure system stability and reliability.

Adopt same automotive chassis electrophores

process and spray-painting for the shell,wear

resistance and corrosion resistance without rust.

Simple Connection

Tap-water quick plug,plug and play,

no need filtering or cooling.

Contain embedded passivation water

treatment system,no need extra water

purification equipment.

High quality ball screw

Absolute encoder servo motor with high quality ball screw,bus interface.Stable structure and high control precision.

Cutting display

Exhibition

Product advantages

1.

High-pressure pump,integrated cutting platform,small footprint,easy moving,fully enclosed,transparent cover design.Secure,clean and easy observation.

2

.220V AC,plug and play,low power consumption.

3

.Professional XL CNC water cutting software communicating with any laptop,can control operation by connecting dongle.

4

.No need installation,easy commissioning.Widely used for high-pressure water cutting test,demonstration,teaching,experiment and other application scenarios;Lead-in DXF file,automatically typeset and generate cutting track. Simple operation,multiple customized cutting logic,suitable for different cutting scenarios;

5

.Absolute encoder servo motor with high quality ball screw,bus interface.Stable structure and high control precision.

6

.Standard double Y-axis gantry structure,stable and reliable,stroke can be customized.

7

.3-axis cutting head.Gem and nozzle can be easily replaced,suitable for both pure water cutting and abrasive cutting.

8

.50mm large stroke Z-axis,suitable for different thickness.

9

.The whole electrical cabinet can be controlled through PLC,cutting pressure can be adjusted flexibly.

10

.Well-known brand high quality electrical components are used for the whole machine to ensure system stability and reliability.

11

.High-pressure pumps with different parameter configuration can be collocated for diversified application scenarios according to customers' need.

Products Parameters

|

Forplus MINI waterjet cutting machine

|

|

|

|

|

||||

|

Model

|

|

Forplus-M0505-30K

|

|

|

||||

|

X、Y、Z travel

|

|

500mm、500mm、50mm

|

|

|

||||

|

Rated pressure

|

|

30000psi(200MPa)

|

|

|

||||

|

Rated power

|

|

4.4KW

|

|

|

||||

|

Rated flow

|

|

0.96L/min

|

|

|

||||

|

Max gem orifice

|

|

0.2mm

|

|

|

||||

|

Machine structure

|

|

gantry structure

|

|

|

||||

|

Transmission mode

|

|

ball screw,linear guide rail

|

|

|

||||

|

Positioning accuracy

|

|

±0.05mm

|

|

|

||||

|

Re-positioning accuracy

|

|

±0.05mm

|

|

|

||||

|

Max no-load speed

|

|

3M/min

|

|

|

||||

|

Inlet water pressure

|

|

2-6bar

|

|

|

||||

|

Water inlet caliber

|

|

Φ12mm

|

|

|

||||

|

Inlet water flow

|

|

6-8L

|

|

|

||||

|

Power requirement

|

|

single phase 220V 50HZ

|

|

|

||||

|

Compressed air pressure

|

|

≥5bar

|

|

|

||||

|

Compressed air caliber

|

|

Φ12mm

|

|

|

||||

|

Size

|

|

1000x1000x1090mm

|

|

|

||||

|

Weight

|

|

450KG

|

|

|

||||

Hot Searches