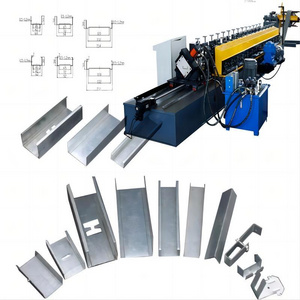

Rolling door roll forming machine

adopts welded steel frame structure, it make sure roof sheet machine can operation more stable

AC frequency conversion motor reducer drive, chain transmission, roller surfaces polishing, hard plating, heat treatment and chrome coating.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Hokang

-

Voltage:

-

220v/380v

-

Power:

-

4000W

-

Dimension(L*W*H):

-

5000*1500*1500mm

-

Weight:

-

2000 kg

-

Product name:

-

L Angle Iron Green Forming Machine

-

Application:

-

Construction Work

-

Raw material:

-

PPGI PPGL GI GL

-

Thickness:

-

0.3--0.8mm

-

Machine Color:

-

Cusotmized

-

Roller material:

-

45#steel Chrome Plated

-

Shaft material:

-

High Grade No.45 Forged

-

Keywords:

-

L Angle Iron Roll Forming Machine

-

Control system:

-

PLC(imported Brand)

-

Decoiler:

-

5 Ton Manual

Quick Details

-

Marketing Type:

-

New Product

-

Production Capacity:

-

20M/MIN

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hokang

-

Voltage:

-

220v/380v

-

Power:

-

4000W

-

Dimension(L*W*H):

-

5000*1500*1500mm

-

Weight:

-

2000 kg

-

Product name:

-

L Angle Iron Green Forming Machine

-

Application:

-

Construction Work

-

Raw material:

-

PPGI PPGL GI GL

-

Thickness:

-

0.3--0.8mm

-

Machine Color:

-

Cusotmized

-

Roller material:

-

45#steel Chrome Plated

-

Shaft material:

-

High Grade No.45 Forged

-

Keywords:

-

L Angle Iron Roll Forming Machine

-

Control system:

-

PLC(imported Brand)

-

Decoiler:

-

5 Ton Manual

Products Overview

L Shaped Angle Iron

Purlin

Profile Roll Forming Making Machine

We are professional manufacturer,we can design the machine as customer requirement.

L Shape Roll Forming Machine is made by cold-formed forming process. It is widely used by people for its energy-saving and environmentally friendly features. It uses less steel to complete the required specified load, and no longer depends on increasing the amount of plates or materials. The mechanical properties of the steel can meet the load requirements, but the mechanical properties of the steel can be improved . Cold bending is a material-saving and energy-saving new metal forming process and new technology. Cold bending is a multi-pass forming and rolling that is arranged in sequence to continuously bend the coils and other metal plates and strips in the transverse direction.

Working Process :

Decoiler—Roll Forming Machine——Hydraulic Press——Hydraulic cutter——Control System——Receiving table

Specification

|

No

|

Item

|

Data

|

|

1

|

Raw material width

|

300-600 mm

|

|

2

|

Sheet effective width

|

80-200 mm

|

|

3

|

Raw material

|

Color steel sheet , Stainless steel or galvanized steel sheet

|

|

4

|

Material thickness

|

0.3-0.8 mm or customized

|

|

5

|

Forming roller material

|

45# steel plated with chrome

|

|

6

|

Shaft diameter

|

40 mm

|

|

7

|

Forming roll station

|

8-16 steps

|

|

8

|

Main motor power

|

3 KW 4 KW 5.5 KW(according to type)

|

|

9

|

Hydraulic power

|

4 KW (according to type)

|

|

10

|

Control system

|

PLC control

|

Our Advantages

L Shaped Angle Iron Purlin Profile Roll Forming Making Machine

The L type Roll Forming machine can use color steel or aluminum plate to make the L shape plate. The forming plate is rolled, closed, and then bent and narrowed by special equipment. It has good weather resistance, simple design, simple installation, safe and durable, and noble. Elegant. The L shape final product can be sprayed with rich colors according to the individual needs of users, and its metal texture and beautiful shape can bring a strong expressive force to the building.

1. The whole machine is controlled by PLC, and multiple safety protections can be set to effectively avoid accidents;

2. The bed is made of steel plate welded parts and tempered to effectively eliminate internal stress and the body is not easy to deform;

3. The forming frame is welded by channel steel;

4. The roll shaft is made of 45# steel, which has been quenched and tempered;

5. The material of forming punching and shearing die is Gr12;

Details Images

Machine Frame Of

Roll Forming Machine

Forming Roller Of

Roll Forming Machine

Roller Material: 45#steel

The roller material processing method :

1. Rough machining

2.Fine polishing

3.Heat treatment58 ℃-62 ℃

4.Cr12 hard chromium plating

The roller material processing method :

1. Rough machining

2.Fine polishing

3.Heat treatment58 ℃-62 ℃

4.Cr12 hard chromium plating

The roller and shaft won't scratch the board. It is long service life and durable.

Decoiler Of

Roll Forming Machine

Capacity: 3T,

Inner Diameter:

507mm-510mmone set is free and deliver with the machine,

Also ,if you need more accurate decoiler, we also have electric decoiler and hydraulic decoiler , want to learn more. click avatar and contact me!!

Also ,if you need more accurate decoiler, we also have electric decoiler and hydraulic decoiler , want to learn more. click avatar and contact me!!

Control Part Of

Roll Forming Machine

Rolling door roll forming machine

control parts have different types, standard type are button control, through press buttons to realize different function.

PLC touch screen type can setting data on the screen, its price is little higher, but is more intelligent and automatic.

PLC touch screen type can setting data on the screen, its price is little higher, but is more intelligent and automatic.

Different electric control cabinets for selection:

Hot Searches