- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

1 year, 1 Year

-

Brand Name:

-

USUN

-

Model Number:

-

WS-AT/2

-

Place of Origin:

-

Guangdong, China

-

Horsepower:

-

None

-

Cable Length:

-

None

-

Outlet Size:

-

NPT

-

Power:

-

None, Pneumatic

-

Theory:

-

Reciprocating Pump

-

Drive power range:

-

Compressed air of 3-8 Bar

-

Pump ratio:

-

From 16:1 ratio to maximum 400:1 ratio

-

Working medium:

-

Oil ,water ,fluid and liquid Co2,diesel

-

Outlet pressure formula:

-

PO= PA x Ratio (PA stands for air driven pressure)

Quick Details

-

Application:

-

Commercial Buildings

-

Pressure:

-

Maximum 400 MPA

-

Voltage:

-

None

-

Warranty:

-

1 year, 1 Year

-

Brand Name:

-

USUN

-

Model Number:

-

WS-AT/2

-

Place of Origin:

-

Guangdong, China

-

Horsepower:

-

None

-

Cable Length:

-

None

-

Outlet Size:

-

NPT

-

Power:

-

None, Pneumatic

-

Theory:

-

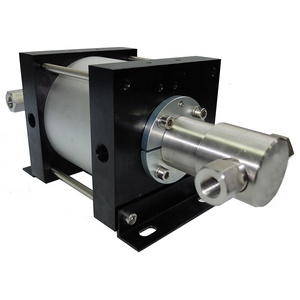

Reciprocating Pump

-

Drive power range:

-

Compressed air of 3-8 Bar

-

Pump ratio:

-

From 16:1 ratio to maximum 400:1 ratio

-

Working medium:

-

Oil ,water ,fluid and liquid Co2,diesel

-

Outlet pressure formula:

-

PO= PA x Ratio (PA stands for air driven pressure)

WHY CHOOSE OUR PUMP SYSTEM?

This brochure introduces pneumatic driven air /Hydraulic boosters and Complete booster system.

These air liquid pump offer a flexible and efficient source for delivering high pressure liquids ,oil

1 . Costing savings : An alternative to the purchase of High Pressure compressor ,our air driven liquid are

C ompact and Require no electrical or mechnical drive connections ,Are powered by the same air that they amplify

and can mounted in any position

2 . High Flow rates at High pressure : W hen High flow rates at high pressure are needed ,the Air Liquid pump

can charge a receiver to an even higher pressure level ,thus storing a volume of air aviable for rapid release at a constant

pressure through a pressure reducing valve

3.Safety Operation : Sa fe Pneumatic Operation-No Heat, Flame or Spark Rish and No need electricity .

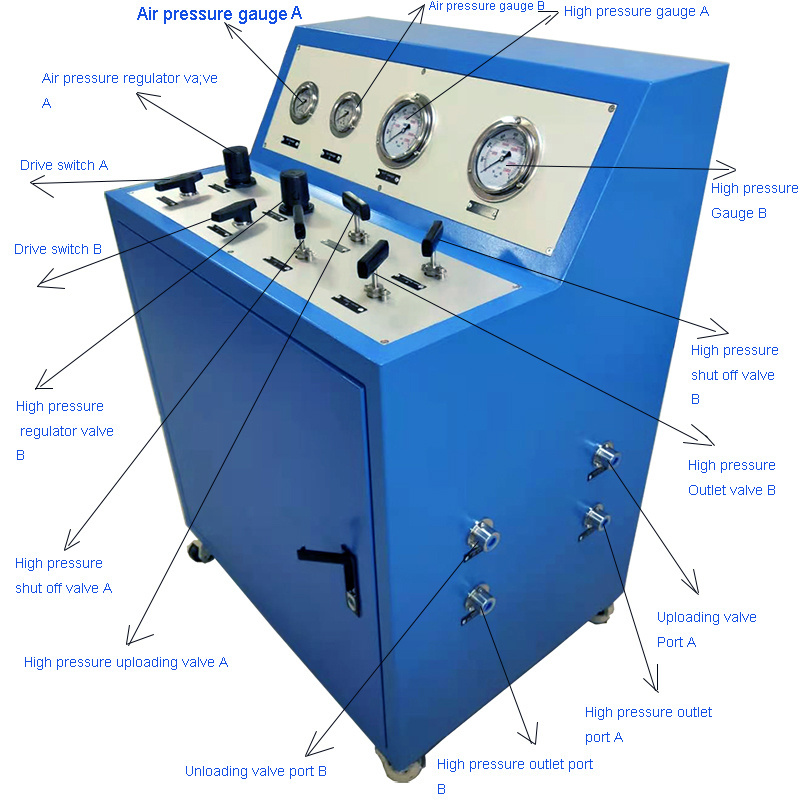

Usun Model:WS-AT/2 Manual control pneumatic hydraulic pressure test pump system with 2 liquid pump inside of cabinet

Application: heat exchangers; boiler pressure vessels; condenser, manufacturing; installation and

maintenance of the connection tube and tube plate of the special expansion equipment

| Item number |

WS-AT 15000 psi High pressure pneumatic hydraulic pump system with valves and gauges and fittings

|

|

|

Air driven Pressure |

3-8 Bar | |

| Dealing with air source | G1/2 ''size air regulator | |

| lubrication | Non-lubricated | |

| Theory of operation |

The Air liquid pump consist of a large reciprcating air driven piston directly and coupled by a connecting rod to small area Air piston.The Air piston operatesin a high pressure air barrel section .Each barrel end contains high pressure inlet and outlet check valves |

|

| Air consumption | 0.9-1.2 M3/Min | |

| Installation | Any |

|

List items |

Function |

| 1) Air regulator valve | Adjustable air regulator used to adjust the air driven pressure ( 3-10 bar) |

| 2) Air pressure gauge | Indicates the air driven pressure |

| 3) High pressure gauge A | Indicates the outlet Liquid boosted pressure |

| 4) High pressure gauge B | Indicates the outlet liquid boosted pressure |

| 5) high pressure manual needle valve | Used to on/off the high outlet pressure |

| 6) AT -1 Double action low pressure air driven liquid pump inside |

Used to increase the pressure from low pressure to a medium high pressure

|

| 7) AT-2 double action high pressure air liquid pump | Used to increase the pressure from medium pressure to high pressure |

| 8) Manual needle valve B | Use hand to control the machine on /off |

| 9) Frame type | Closed cabinet type |

| 10) Uploading valve | Use that to release high pressure |

Product advantages

1, can be arbitrarily set the the pressure holding time to ensure the expanding quality;

2, step up, unloading speed is fast, expansion joint speed increased exponentially;

3, the 10-400mm thickness of the tube plate for the full thickness of a one-time uniform expansion;

4.can be arbitrary depth of the middle tube plate or multi tube plate heat exchanger for full thickness expansion;

5, tube expanding of tube or seam welding;

6. The residual stress of the device is low, and the gap corrosion is not easy to be produced;

7, heat exchanger expansion after the axial not long and slightly shrink, it is conducive to reduce the running noise;

8, the hole diameter of the pipe is large, and the diameter of the expanding head can be adjusted appropriately;

9, the expansion joint is free of pollution, the first expansion after welding is not affected;

10, with the tube box of the heat exchanger at the edge of the expansion can be directly expanded (the maximum grinding head is 0.3mm) is very convenient

;

Main technical parameter of AT pneumatic liquid pump

Main circuit of such pump system

Shipping

| By sea | C heapest but longest option 18~30 days by sea delivery for mass shipment |

| By air | More expensive than sea delivery, But cheaper than express 5~7 days by air to airport. |

| By express |

door to door service,the fastest and most expensive one, 3~5 day for DHL /Fedex /UPS/TNT express

|

1. 24-hour technical support by email

2. calling or door-to-door service

3.Whatsapp or Wechat are avaiable for 24 Hours