- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

2.2

-

Weight (KG):

-

500

-

Power:

-

Hydraulic

-

Product name:

-

nc pipe bending machine

-

Color:

-

Optional Tube Bending Machine

-

Design to Made Service:

-

YES

-

Technology:

-

Cold Bending

-

Control:

-

NC

-

Operation:

-

Easy and Stable

-

Processing Types:

-

Metal Pipe

-

PLC:

-

OMRON

-

Electrical Parts:

-

SCHNEIDER, FRANCE

Quick Details

-

Max. Bending Angle (Deg):

-

190

-

Bending Precision (Deg):

-

1

-

Place of Origin:

-

Jiangsu, China

-

Power (kW):

-

2.2

-

Weight (KG):

-

500

-

Power:

-

Hydraulic

-

Product name:

-

nc pipe bending machine

-

Color:

-

Optional Tube Bending Machine

-

Design to Made Service:

-

YES

-

Technology:

-

Cold Bending

-

Control:

-

NC

-

Operation:

-

Easy and Stable

-

Processing Types:

-

Metal Pipe

-

PLC:

-

OMRON

-

Electrical Parts:

-

SCHNEIDER, FRANCE

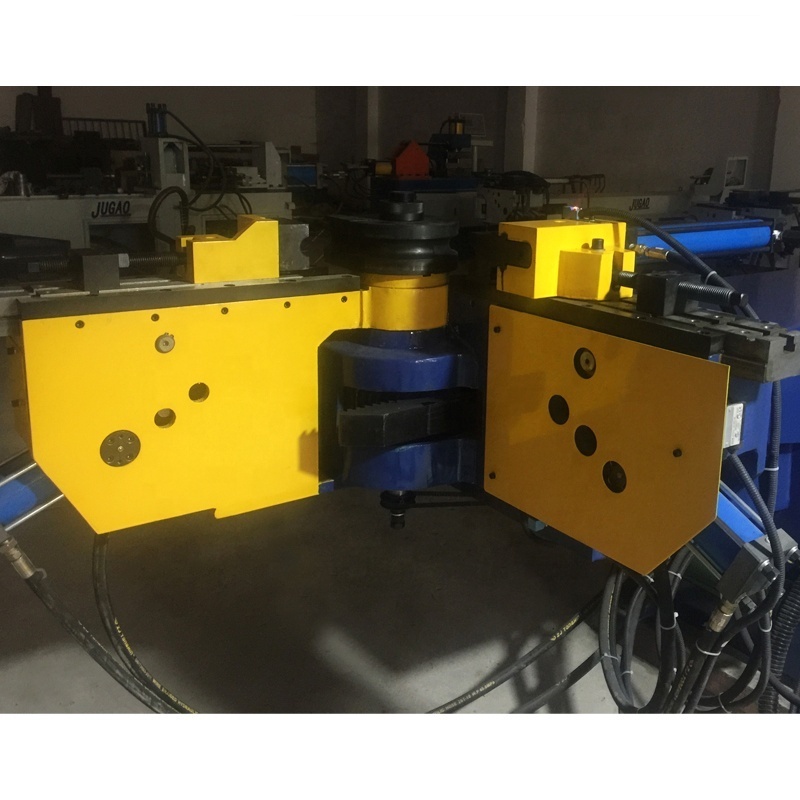

Electric Single Head Hydraulic Tube Pipe Bender Rollers Machine For Bending Tube Semi Automatic Pipe Bending Machine

Product Description

1.PLC control, easy to set programs and operate .

2.Slowly returning of mandrel , make good shape and appearance of the angle .

3.Rotating is controlled by servo-motor, more precise .

4.Memory 100 sets records with each record setting 20 auto rotating and bending angles .

5.Moveable control platform with touch-screen , more convenient .

6.Mistakes self-checking on the screen , help to solve problem immediately .

7.Key parts use the imported brands .

8.Hydraulic power, processing more smoothly .

9.Die material use high quality steel, hardness high and long life use, the hardness not below HRC50; dies including bending die, clamping die, crease resistant die, guide die, Wiper Die(Optional), Ball Mandrel(Optional).

Standard accessories

1. One pair of standard mould (wheel mould, clamping mould and sliding plate mould)

2. One set of common tools

Special accessories

Auxiliary pushing device, core rod, wrinkle-proof mould, shaped mould, forming mould

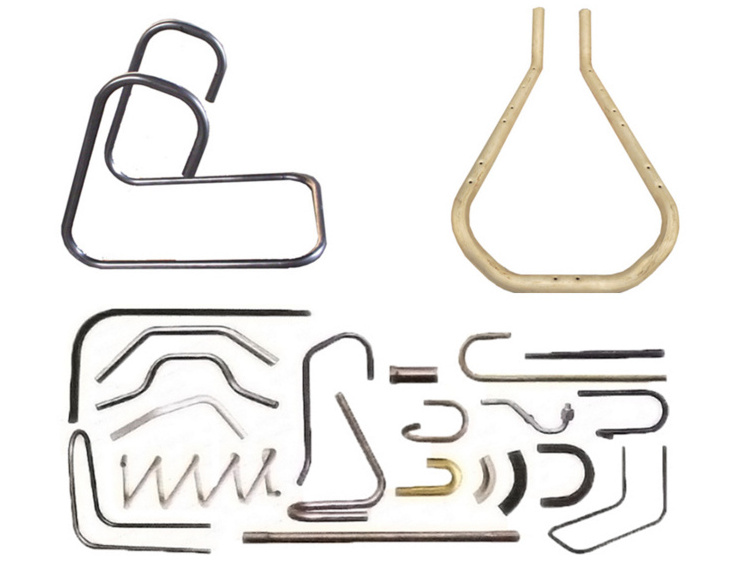

Categories of bent materials

Steel tube, stainless steel tube, copper tube, aluminum tube and multiple-unit tube

Shapes of bent materials

Round tube, square tube, elliptical tube, plum blossom-shape tube, shaped tube, U-steel, angle steel, I-steel and flat steel, etc.

Recommended using units

Automobile spare parts (brake line, bumper bar, silencer and seat, etc.). Industries including motorcycle manufacturing, electromobile manufacturing, iron art, fitness equipment, air conditioning, bicycle, steel furniture, sanitary and bathroom equipment, seats for relaxation, petroleum pipeline, shipbuilding and boiler.

Technical parameter

| Main Technical Parameter | Unit | 18NCB | 28NCB | 38NCB | 50NCB | 63NCB |

| Max. Bending Capacity | mm | 18×2 | 28×2 | 38×2 | 50×2 | 63×4 |

| Bending Radius Region | mm | 20-150 | 20-180 | 20-200 | 20-250 | 25-350 |

| Bending Angle Region | Degree | 0-190° | 0-190° | 0-190° | 0-190° | 0-190° |

| Effective Length Over Mandrel | mm | 2000 | 2000 | 2000 | 2200 | 2500 |

| Oil Pressure System Motor | kw | 2.2 | 2.2 | 4 | 5.5 | 7.5 |

| Max. Pressure | kg/cm | 160 | 160 | 160 | 160 | 160 |

| Machine Dimension | mm | 2300×550×1300 | 2500×650×1300 | 2500×700×1300 | 3000×700×1300 | 3200×750×1300 |

| Machine Weight | kg | 500 | 600 | 750 | 1220 | 1400 |

| Main Technical Parameter | Unit | 75NCB | 89NCB | 115NCB | 130NCB | 168NCB |

| Max. Bending Capacity | mm | 75×5 | 89×8 | 115×8 | 130×12 | 168×16 |

| Bending Radius Region | mm | 30-350 | 30-450 | 40-550 | 50-650 | 60-850 |

| Bending Angle Region | Degree | 0-190° | 0-190° | 0-190° | 0-190° | 0-190° |

| Effective Length Over Mandrel | mm | 3200 | 3800 | 4500 | 4600 | 4850 |

| Oil Pressure System Motor | kw | 7.5 | 11 | 15 | 18.5 | 22 |

| Max. Pressure | kg/cm | 160 | 160 | 160 | 160 | 160 |

| Machine Dimension | mm | 3650×1000×1400 | 4400×1150×1350 | 5800×1500×1350 |

6000×1500 ×1350 |

6300×2450 ×1500 |

| Machine Weight | kg | 2380 | 4500 | 6500 | 11500 | 12000 |

Guarantee period:

Our product quality guarantee period is 12 months from B/L date. During guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by customers’ incorrect operations, we will provide customers spare parts at cost price. We also can offer flexible extended warranties according to the actual situation.

After-sales services:

Our engineer can go to your factory for installation and showing operation details on condition of you provide the round-trip air tickets, visa formalities, food and accommodation. In turn, your engineers can come to our factory for learning the installation, operation and maintenance for free.

Why Choose Us:

1. We will run the machine for a few days, and use your materials to do the test. Only guarantee the machine shows best performance, and then we will ship out.

2. Our elite teams can provide you professional, customized, and all-round services around the clock. If you need any help, contact us by WHATSAPP, Skype, Email or Telephone.

How can we provide you efficient services (metal processing solution):

There are Three Steps as following:

1. Gather your requirements based on your real working situation.

2. Analyze your information and provide our feedback.

3. Offer options based on your specific needs. For instance, reg. standard products, we can offer professional recommendations; reg. non-standard products, we can offer professional designing.