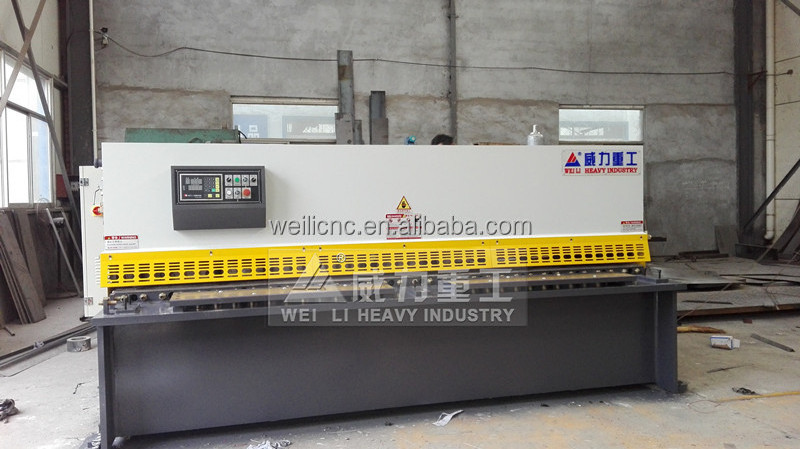

- Product Details

- {{item.text}}

Quick Details

-

Blade Length (mm):

-

2500 mm

-

Backgauge Travel (mm):

-

20 - 500 mm

-

Throat Depth (mm):

-

100 mm

-

Brand Name:

-

WEILI HEAVY INDUSTRY

-

Power (kW):

-

5.5 kW

-

Weight (KG):

-

5000 KG

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

3120x1450x1550

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Color:

-

Can be free to choose

-

Machine type:

-

Hydraulic pendulum shearing machine

-

Type:

-

Metal cutting machime

-

Function:

-

Shearing and cutting

-

The machine body:

-

Steel plate welded and seamless

-

Guide:

-

Linear guideway

-

Cutting:

-

Long and super thick material

-

Structure:

-

Guillotine shearing machine

-

After Warranty Service:

-

Field maintenance and repair service

Quick Details

-

Max. Cutting Width (mm):

-

2500

-

Max. Cutting Thickness (mm):

-

4 mm

-

Shearing Angle:

-

1°30'

-

Blade Length (mm):

-

2500 mm

-

Backgauge Travel (mm):

-

20 - 500 mm

-

Throat Depth (mm):

-

100 mm

-

Brand Name:

-

WEILI HEAVY INDUSTRY

-

Power (kW):

-

5.5 kW

-

Weight (KG):

-

5000 KG

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

3120x1450x1550

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Color:

-

Can be free to choose

-

Machine type:

-

Hydraulic pendulum shearing machine

-

Type:

-

Metal cutting machime

-

Function:

-

Shearing and cutting

-

The machine body:

-

Steel plate welded and seamless

-

Guide:

-

Linear guideway

-

Cutting:

-

Long and super thick material

-

Structure:

-

Guillotine shearing machine

-

After Warranty Service:

-

Field maintenance and repair service

1. Steel welded structure, stress elimination by vibration, high mechanical strength, and exceptional rigidity.

2. The hydraulic drive type structure, the cutter saddle circles a fixed axis for circle moving.

3. Decrease the force of fulcrum through leverage to prolong working life.

4. Nitrogen cylinder return, simplifying the hydraulic system to make running more stable.

5. with fast and flexible gap adjusting mechanism for high shearing accuracy

6. Equipped with Lighting Alignment Device for easy shearing.

7. Back Gauge size and shearing times controlled by CNC system, back gauge with high precision ball screw, stable operation and precise positioning.

8. The NC system adopts frequency conversion control technology, with multi-step programming function, simple and easy to operate.

9. Safety barrier device all around the machinery, electrical cabinets equipped with Open door cut-off function, emergency stop button around front and back, protective cover foot switch to ensure safe working.

| Model | Unit | QC12Y-4×2500 |

| Max.cutting thickness | mm | 4 |

| Max.cutting width | mm | 2500 |

| Shearing angle | ° | 1°30′ |

| Material intensity | Mpa | ≤450 |

| Backgauge range | mm | 20-500 |

| Stroketimes | times/min | 18 |

| Column spacing | mm | 2700 |

| Motor power | Kw | 5.5 |

| Weight | Kg | 5000 |

| DimensionL×W×H | mm | 3120×1450×1550 |

1. QC12Y series machines, assemble simple numerical control system.

2. Has the position of CNC after display, soft limit, one way to tip clearance, shear automatic counting function.

3. Equipped with encoder, cooperate with simple nc system, make the blocking show more accurate, thus to further improve the shearing precision of this machine.