- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

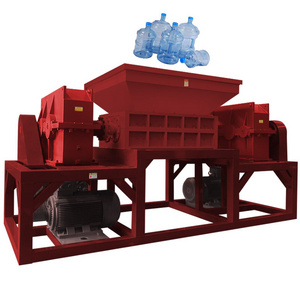

plastic bottle recycling machine

-

Application:

-

plastic bottle recycling machine

-

Production Capacity (kg/h):

-

100 - 2000

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

870*650*1650mm

-

Power (kW):

-

150

-

Weight (T):

-

15

-

Machine name:

-

plastic bottle recycling machine

-

application:

-

waste plastic bottle

-

plastic bottle crusher advantage:

-

High precision,high speed

-

plastic bottle crushercapacity:

-

200-2000kg per hour

-

Input voltage:

-

AC380V,50-60hz

-

final size:

-

10-200mm

-

total weight:

-

plastic bottle recycling machine 20t

-

plastic recycling crusher dimension:

-

38950mm*2200mm*3000mm

-

plastic recycling crusher color:

-

plastic bottle recycling machine any

-

plastic shredder speed:

-

plastic shredder high

Quick Details

-

Machine Type:

-

PP PE Bottle Washing Line

-

Max.Production Capacity (kg/h):

-

10000

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

plastic bottle recycling machine

-

Application:

-

plastic bottle recycling machine

-

Production Capacity (kg/h):

-

100 - 2000

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

870*650*1650mm

-

Power (kW):

-

150

-

Weight (T):

-

15

-

Machine name:

-

plastic bottle recycling machine

-

application:

-

waste plastic bottle

-

plastic bottle crusher advantage:

-

High precision,high speed

-

plastic bottle crushercapacity:

-

200-2000kg per hour

-

Input voltage:

-

AC380V,50-60hz

-

final size:

-

10-200mm

-

total weight:

-

plastic bottle recycling machine 20t

-

plastic recycling crusher dimension:

-

38950mm*2200mm*3000mm

-

plastic recycling crusher color:

-

plastic bottle recycling machine any

-

plastic shredder speed:

-

plastic shredder high

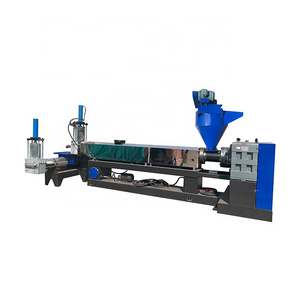

waste plastic crushing and washing machine

waste plastic crushing and washing machine

Application

The whole production line deal with waste plastic such as PP PE film bags, LDPE agriculture film,LLDPE shrink film,PP woven bags(big bags),or rigid plastics(bottles,barrles,pipes...) etc.

This production line is high automatic operating and low consume, can save labor, save power and save water, easy to maintenance.

With advanced design, concepts and technologies to suit different status of waste plastic bags/films. This PP PE plastic recycling machine could layout as "L", "S" or "U" shape according different workshop.

Features

1. Belt conveyor: conveying dirty plastic film or bag into crusher. If too much scrap iron, metal detector may be needed.

2.Crusher: can crushing with water, cut plastic film or bag into small pieces

3.Screw loader: load film pieces into the next step

4.High-speed washing machine: Washing out the sand, soil and loading the material

5. Washing tank: separate the sand, soil and other dirties

6.Dewatering machine: Remove the water from the material

7.Drying system and silo:Blowing the hot air from the heater will dry the material in the pipe. Finally storage.

Technical Parameter

3.What we can do

| 1. | We can sent videos to you for your checking |

| 2. | Also can test the machine for you if you sent us the sample. |

| 3. | Can change the 304 stainless steel material to 316 Stainless steel |

| 4. | Can provide special design parts according to your material's characteristics |

Packaging and Shipping

We have been cooperating with several large transport agents and

shipping companies for long terms,the machines will be transported

to you safety and timely.

Delivery time

Normally, 7-10 working days after received your payment.

3.Any problems occur while using, professional advice will be given by us.

4.Can supply various kinds of documents for you to do customs clearance .