- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

ZW-2.0/10-16

-

Voltage:

-

220V/380V/415V(customizable)

-

Dimension(L*W*H):

-

1400*800*1100mm

-

Weight:

-

850KG

-

Working Pressure:

-

1.6 bar

-

Product name:

-

propane compressor

-

Cooling method:

-

Cold air and cold water

-

Application:

-

refrigeration

-

Color:

-

customizable

-

Certification:

-

ISO9001:2015

Quick Details

-

Applicable Industries:

-

refrigeration

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

AOT

-

Model Number:

-

ZW-2.0/10-16

-

Voltage:

-

220V/380V/415V(customizable)

-

Dimension(L*W*H):

-

1400*800*1100mm

-

Weight:

-

850KG

-

Working Pressure:

-

1.6 bar

-

Product name:

-

propane compressor

-

Cooling method:

-

Cold air and cold water

-

Application:

-

refrigeration

-

Color:

-

customizable

-

Certification:

-

ISO9001:2015

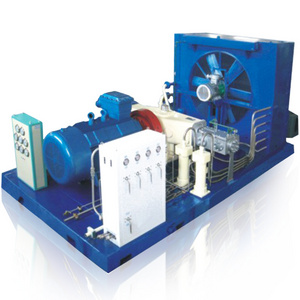

Custom Air Cooler Propane Screw Compressor

The compressor adopts oil-free lubrication structure and can run continuously for a long time. Meet the process requirements, suitable for all kinds of gases. All oil-free lubrication compressors with various parameters and requirements can be customized according to customer requirements.

Propane Compressor System Composition

1.Compressor lubrication system

2.Compressor oil separation system

3.propane refrigeration system

4.Oil distiller return system

5.Electrical instrument , high voltage start

Principle of refrigeration:

In the process of refrigeration, the method of obtaining low temperature is usually achieved by adiabatic expansion of high pressure and normal temperature fluid. Propane compression refrigeration consists of four basic processes: compression, condensation, expansion and evaporation.

|

Compressor

|

Product Model

|

|

ZW-2.0/10-16

|

||

|

|

Type

|

|

Z Type

|

||

|

|

Compressed medium

|

|

Propane

|

||

|

|

Nominal volume flow(Nm³/min)

|

|

2.0

|

||

|

|

Compression stage

|

|

1

|

||

|

|

Cylinder number

|

|

2

|

||

|

|

Driving mode

|

|

Coupling

|

||

|

|

Noise (sound pressure level) dB(A)

|

|

≤75

|

||

|

|

Cooling mode

|

|

Water cooling

|

||

|

|

Rotational speed (r/min)

|

|

740

|

||

|

|

Suction pressure (MPa G)

|

|

1.0

|

||

|

|

Discharge Pressure (MPa G)

|

|

1.6

|

||

|

|

Suction temperature (℃)

|

|

≤40

|

||

|

|

Discharge temperature (℃)

|

|

≤150(after cooling≤40)

|

||

|

|

Lubrication type

|

Crankshaft, connecting rod, cross head

|

Oil lubrication

|

||

|

|

|

Cylinder, Packing

|

Oil-free lubrication

|

||

|

Motor

|

Model

|

|

YB3-250M-8

|

||

|

|

Explosion-proof grade

|

|

DIIBT4

|

||

|

|

Rotational speed (r/min)

|

|

740

|

||

|

|

Rated voltage (V)

|

|

380

|

||

|

|

Rated frequency(Hz)

|

|

50

|

||

|

|

Rated current (A)

|

|

63.4

|

||

|

|

Rated power (Kw)

|

|

30

|

||

|

Compressor size (L×W×H) mm

|

≈1400×800×1100

|

|

|

||

|

Weight(kg)

|

≈850

|

|

|

||

Note:With the parameters of the logo will be subject to leave the factory

Scope of supply

|

No.

|

Name

|

Number

|

Note

|

|

1

|

Compressor host

|

1

|

/

|

|

2

|

Motor

|

1

|

/

|

|

3

|

Gas-liquid separator

|

1

|

/

|

|

4

|

Water-cooling system

|

1

|

/

|

|

5

|

Shared chassis

|

1

|

/

|

|

6

|

The relief valve

|

1 set

|

/

|

|

7

|

Coupling

|

1 set

|

/

|

|

8

|

Piping components

|

1 set

|

/

|

|

9

|

Random spare parts

|

1 set

|

/

|

|

10

|

The technical documentation

|

1 set

|

/

|

|

11

|

Explosion-proof control cabinet

|

1 set

|

/

|

Five reasons to choose AOT compressor:

1.Overall skid-mounted humanized design:

Adopt integral skid-mounted design, compact structure, more convenient operation and maintenance.

2."Tailored" for customers:

According to the usage parameters and requirements provided by customers, provide the best solution to fully meet the needs of customers.

3.A machine a file:

Record the relevant data and information of the whole process of the equipment and the delivery place in detail, so as to facilitate the timely tracking service.

4.24Monthly free warranty

All factory compressors are Free warranty for 24 months, lifetime warranty, so that users can be more assured.

5.Perennial spare parts support

Our company stock spare parts for every factory compressor, to ensure the long-term use of users, remove users' worries.

Bengbu AOT Compressor Co.,

is located in Bengbu Anhui.China. This is the world's important compressor production base. The company specializes in the development, manufacturing and sales of compressor products. The company is mainly engaged in the new type of high efficiency and environment-friendly special gas compressor for oxygen, hydrogen, menthane , liquefied gas, natural gas and gas station and chemical industry. The company has always adhered to the scientific and technology and design concept of compressor industry at home and abroad, combined with the actual situation in China, and applied scientific enterprise management and advanced manufacturing techiology in the design, development, assembly process and testing means. Product quality, to create first-class products.

Two-years warranty period for whole machine except of tubes and human factors etc, and 24-month of after-sale service from the date when you receive machine or 24 months when installation finished;

Consultant services for whole machine life, and 24 hours technical support by email;

UPS, English software, user manual and the installation & debugging by our experienced technicians.

Please tell me inlet pressure,outlet pressure,voltage frequency,capacity,the usage of compressor, I will recommend a suitable gas compressor.

If you want to send me the inquiry,please fill the below technical information:

1. The flow rate: _____Nm3/hr

2. Inlet pressure: _____ Bar

3. Discharge pressure: _____ Bar

4. Voltages and Frequency : ______V/PH/HZ

5. Natural gas compressor application:

If you are interested in it,please contact me freely