- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Ruding

-

Standards:

-

AAR, UIC, EN, GOST, IRIS, KSR, BS, JIS,TB

-

Application:

-

Train, Railway Wagon, Passenger Car, Locomotive

-

Process:

-

Forging-machining-heat treatment-machining-inspection-package

-

Certifications:

-

ISO9001, ISO14001, OHSAS18001,TSI, AAR

-

Wheel Diameter:

-

100mm to 1250mm

-

Inspection:

-

Chemical analysis, Metallographic, Mechnical analysis, UT, MT,etc

-

Service:

-

OEM\ODM

-

Wheel type:

-

Single flange/Double flange

-

Warranty:

-

1 Year

Quick Details

-

Material:

-

Iron, Steel

-

Dimensions (L x W x H) (mm):

-

Customized, As required

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Ruding

-

Standards:

-

AAR, UIC, EN, GOST, IRIS, KSR, BS, JIS,TB

-

Application:

-

Train, Railway Wagon, Passenger Car, Locomotive

-

Process:

-

Forging-machining-heat treatment-machining-inspection-package

-

Certifications:

-

ISO9001, ISO14001, OHSAS18001,TSI, AAR

-

Wheel Diameter:

-

100mm to 1250mm

-

Inspection:

-

Chemical analysis, Metallographic, Mechnical analysis, UT, MT,etc

-

Service:

-

OEM\ODM

-

Wheel type:

-

Single flange/Double flange

-

Warranty:

-

1 Year

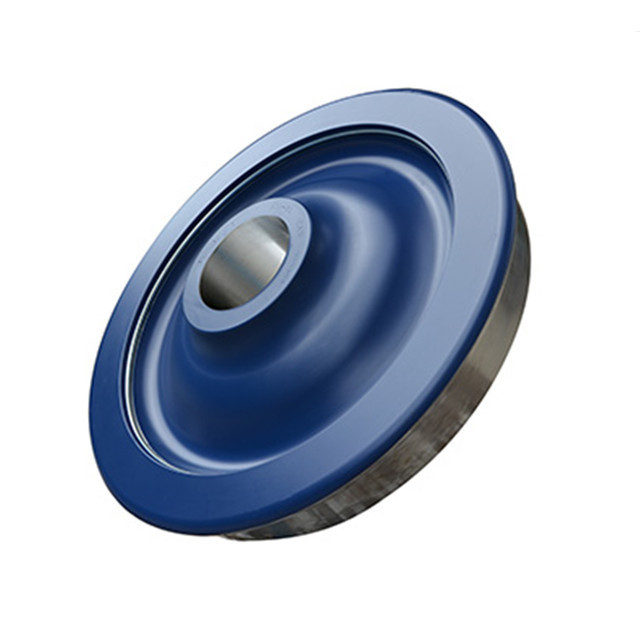

Ruding Rail specializes in the design, production and assembly of all types of wheels for passenger and freight rail transport including monobloc, tire-typed, elastic and low-noise wheels.

The wheels we provide can meet most of the international standards, such as AAR M-208, AAR M-107, UIC 812-3, BS 5892-3, JIS E5402-2, IRS R34, TB/ T 2817.

We can also customize train wheels according to the specifications and drawings provided by customers.

Specification:

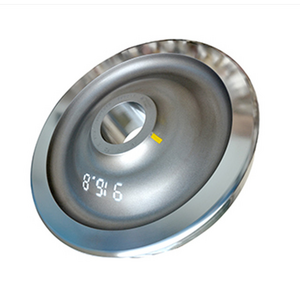

| Forging | Forged steel railway wheel |

| Material | ER6,ER7,ER8,ER9,R7T,R8T,R9T,CL60 |

| Diameter | Φ500 toΦ1250mm |

| Application | Freight Wagon Wheels, Passenger Coach Wheels, Locomotive Wheels and many other industrial or mine vehicles wheels |

| Inspection | Chemical composition; UT, MT; mechanical; property; dimension check |

| Standard | IRS,BS,UIC,AAR,BN,GB,TB/T,EN |

| QC Doc | Chemical;composition;report;mechanical;properties;report;;UT;test;report;;heat;treatment;report;;dimensions;check;report. |

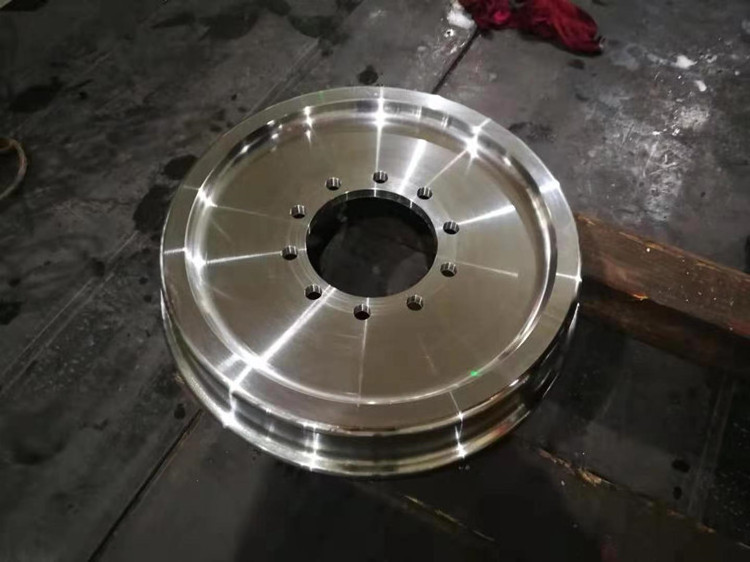

Manufacturing process:

1. Steel Melting 2. Round Billet Sawing Cutting 3. Heating 4. Phosphorus 5. Stamping Forming 6. Rolling 7. Bending Punch 8. Hot Stamping 9. Laser Measurement 10. Drop Stack 11. Roughing 12. Hardening 13. Tempering 14. Sampling 15. Pre-processing 16. Finishing 17. The Cold Print 18. Static Equilibrium 19. The Cold Print 20. Hardness Testing 21. Ultrasonic Testing 22. Magnetic

Particle Testing 23. Shot Peening 24. Painting Packaging

1. OEM and customized service.

2. Full machining, primer coating, surface treatment.

3. Complete material testing process.

4. Quality control

If you have any questions, pls feel free to contact us