- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

100

-

Weight (KG):

-

900 KG

-

Additional Capabilities:

-

homogenizer

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Rick

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

8 kW

-

Product name:

-

emulsifying mixer

-

Keyword:

-

emulsifying mixer

-

Heating method:

-

Electric Steam Heating

-

Function:

-

emulsion, homogenizing, mixing

-

Machine Type:

-

Vacuum Mixer Mixing Machine

-

Homogenizing speed:

-

0-3000RPM

-

Capacity:

-

200-500L

-

Application scope:

-

Chemical Cosmetic Food

-

Stirrer type:

-

Wall Scraper Mixer

Quick Details

-

Barrel Volume (L):

-

100

-

Max. Loading Volume (L):

-

100 L

-

Range of Spindle Speed(r.p.m):

-

0 - 4500

-

Max. Loading Capacity:

-

100

-

Weight (KG):

-

900 KG

-

Additional Capabilities:

-

homogenizer

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Rick

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

8 kW

-

Product name:

-

emulsifying mixer

-

Keyword:

-

emulsifying mixer

-

Heating method:

-

Electric Steam Heating

-

Function:

-

emulsion, homogenizing, mixing

-

Machine Type:

-

Vacuum Mixer Mixing Machine

-

Homogenizing speed:

-

0-3000RPM

-

Capacity:

-

200-500L

-

Application scope:

-

Chemical Cosmetic Food

-

Stirrer type:

-

Wall Scraper Mixer

Hydraulic lift toothpaste making jar cream mixing agitador jomeginizador homogenizer mixer vacuum cosmetic emulsifying machine

T he emulsifying mixer is a kind of versatile equipment which can make liquid, suspended solids and particles substance into homogeneous thinning. homogenizer works by breaking or subdividing the dispersed components into smaller particles and then distributing them evenly throughout the mixture, to produce a uniformly consistent mixture. Homogenizing is primarily used with components that are not dissolvable in each other, that are barely mixable or not mixable at all. Solids can usually be homogenized by stirring.

Application:

1.

Daily Chemical & Cosmetics Industry:

Such as baby cream, skin cream, face cream, shaving cream, shaving cream, lotion, shampoo, toothpaste, cold cream, sunscreen cream,face cleanser, moisture cream, liquid soap etc;

2. Food Industry:

Sauce, mayonnaise, juice, cheese, oral, nutrition, infant food, chocolate, sugar , tomato paste etc;

3. Health care Industry:

Paste, ointment, Latex, emulsions, oral syrup, liquid. etc;

4. Chemical Industry:

Latex, saponification products, paints, coatings, resins, adhesives, lubricants and the like.

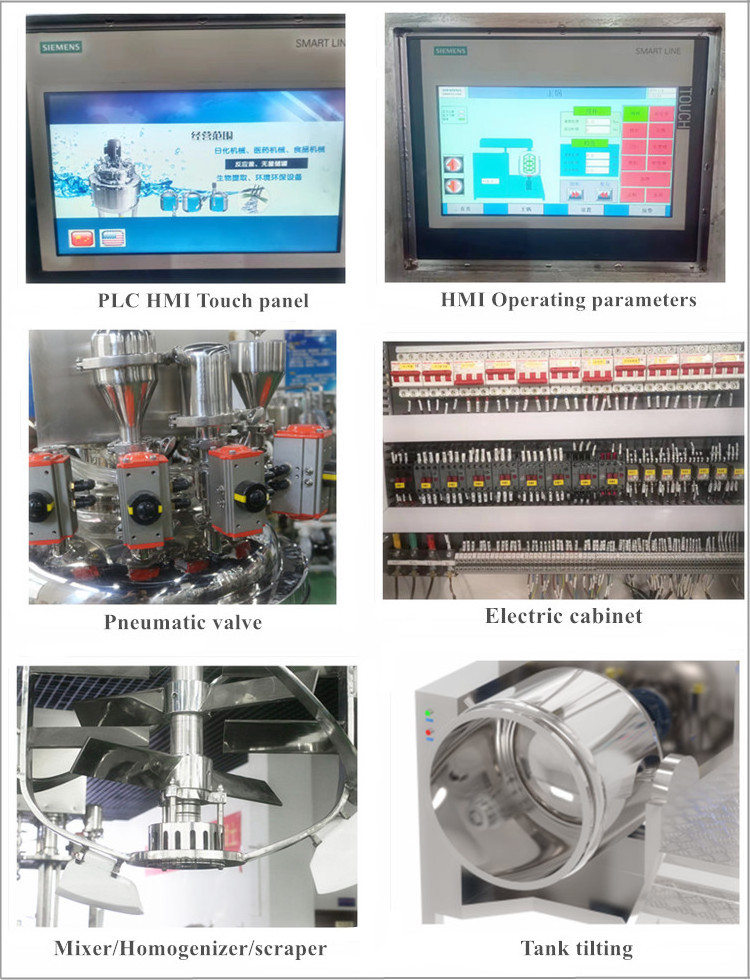

Features description:

1,

PLC control v

acuum

emulsif

ying

mixer

is control by PLC system, can setting the parameter by HMI touch panel,

the

machine

material contacted part

with product

is made by SS316L, inside and outside of the equipment are with mirror polishing and get to GMP standard.

2, PTFE scraping board cater to body of

blending

groove and scrape out viscosity material on tank wall

s,

is suitable to every kind of complicated recipe and achieve optimizing effect.

3,

PLC control v

acuum

emulsif

ying

mixer

the homogenizer

is installed

on

top

for easy to make machine cleaning

. During few production,

i

t can exert

emulsion

effect fully.

4.

PLC control v

acuum

emulsif

ying

mixer

is frequency conversion timing control and can setting the homogenizing time, it adopts the most advanced German-technology,

t

he speed of high emulsification is 0-3000r/min, you can

customized

highest rotate speed up to 4500r/min

5, Mightiness balance isotactic curve rotor is matched with stator with corresponding structure to realize liquid high-capability cut,

rubbing,

centrifugal to make sure exquisite and slick product.

6. Finished products can be discharged by

p

ositive pressure

or tilt the tank, or by

transfer

pump.

Technical Parameters:

|

Model |

Working capacity |

Stir motor/speed |

Homogenizer motor/speed |

||

|

RHJ-300L |

300L |

2.2Kw |

0-63RPM |

4Kw |

0-3000RPM |

|

RHJ-500L |

500L |

3Kw |

0-63RPM |

5.5Kw |

0-3000RPM |

|

RHJ-1000L |

1000L |

4Kw |

0-63RPM |

7.5Kw |

0-3000RPM |

|

RHJ-2000L |

2000L |

5.5Kw |

0-63RPM |

11Kw |

0-3000RPM |

|

RHJ-3000L |

3000L |

7.5Kw |

0-63RPM |

15Kw |

0-3000RPM |

GMP Project case: