- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

100 KG

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HANCHUANG

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

100*70*130cm

-

Power (kW):

-

2.2 kW

-

Name:

-

mixing machine

-

Motor:

-

2.2kw

-

Volumn:

-

customized

-

Mixing type:

-

360 Degrees Rotation

-

Application scope:

-

dry powder, mill and others

-

Capacity:

-

customized

-

Color:

-

SLIVER

-

MOQ:

-

1 SET

-

Mixing time:

-

5-10 Minutes

Quick Details

-

Barrel Volume (L):

-

customized

-

Max. Loading Volume (L):

-

300 L

-

Max. Loading Capacity:

-

300

-

Weight (KG):

-

100 KG

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HANCHUANG

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

100*70*130cm

-

Power (kW):

-

2.2 kW

-

Name:

-

mixing machine

-

Motor:

-

2.2kw

-

Volumn:

-

customized

-

Mixing type:

-

360 Degrees Rotation

-

Application scope:

-

dry powder, mill and others

-

Capacity:

-

customized

-

Color:

-

SLIVER

-

MOQ:

-

1 SET

-

Mixing time:

-

5-10 Minutes

High Quality Stainless Steel Durable Rotary Food Drum Mixer /automatic Drying powder mixer +8618737189043

Introduction of mixing machine

The mixer is a new, high-efficiency, fine-container-rotating, stirring-type mixing equipment. It is used for the uniform mixing of various powdery and granular materials. It has a high degree of mixing and can also achieve good results for ingredients with a small amount of addition. Mixing degree: The machine adopts mechanical seal, the powder will not leak, and the bearing life is long; the machine has high mixing efficiency, high work efficiency, low labor intensity and convenient operation. It can be used in magnetic powder, ceramics, chemical, food, feed and other industries.

Features of mixing machine

This equipment has the characteristics of simple and reasonable structure, convenient maintenance, low power, safety and reliability, high mixing uniformity, no residue, and good sealing performance. It is suitable for mixing powder additives and trace elements in many industries.

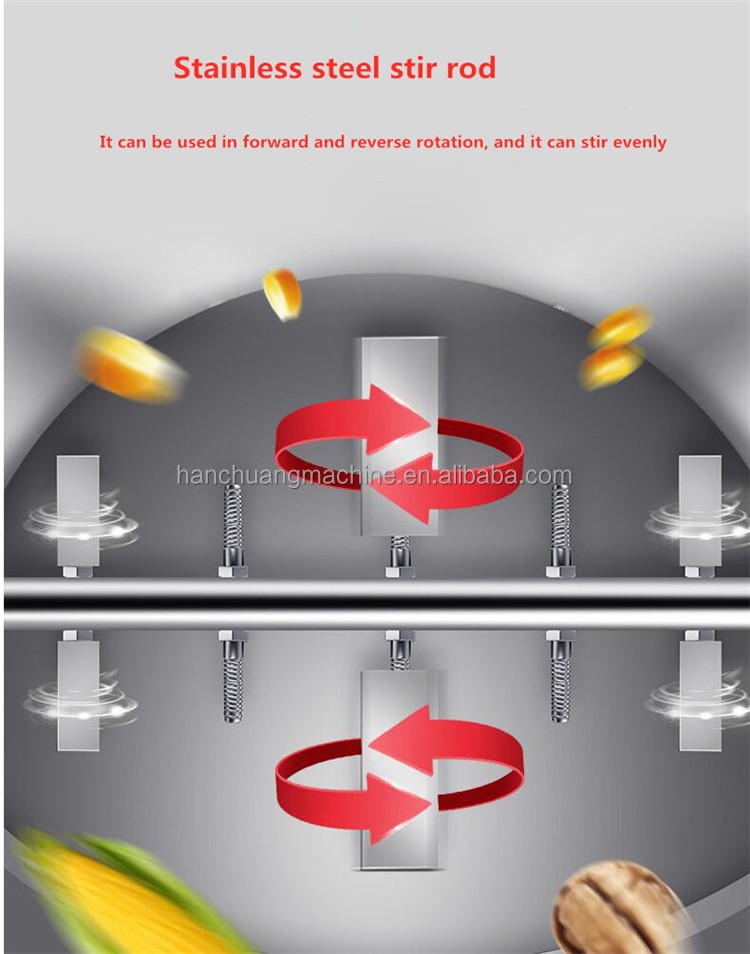

The mixing principle of the mixer:

The mixer rotates 360 degrees and flips, and there is a mixing blade in the middle of the mixer half. When the mixer is running, the mixing blades rotate at the same time. The rotating double cone makes the material in the cylinder tumbling and mixing. The high-speed rotating mixing blade breaks up the agglomerated materials, so that the materials are quickly mixed in the cylinder.

Details of mixing:

Parameters of mixer

|

Model |

HC-M30 |

HC-M50 |

HC-M100 |

|

Power |

2.2KW |

2.2KW |

3KW |

|

Voltage |

220V/380V |

220V/380V |

220V/380V |

|

Motor speed |

1440r/min |

1440r/min |

1440r/min |

|

Mixing time |

5-10mins/time |

5-10mins/time |

5-10mins/time |

|

Volume |

60L |

90L |

180l |

|

Mix bowl diameter |

400mm |

460mm |

590mm |

|

Mix bowl length |

720mm |

760mm |

960mm |

|

Machine size |

100*70*130cm |

102*75*140cm |

120*900*155cm |

Install

1. The ground on which the equipment is installed should be level.

2. All moving parts rotate flexibly, and all fasteners must be firm.

3. Sufficient grease should be added to each lubrication place.

Precautions for equipment operation:

1. Check whether the fasteners are fastened in place and there should be no foreign objects in the drum.

2. In the dry running test, the moving parts should rotate flexibly.

3. The material can only be fed after the machine is running normally, and the mixed material should enter the drum at the same time. After each batch takes 5-10 minutes, the material can be discharged.

4. If there is an abnormal sound response during the operation of the machine, the machine will be shut down for inspection immediately, and production can only be carried out after troubleshooting

Mixing pictures

Packaging & Shipping

1. Testing Machine before package

2. Package : Inside plastic bag, outside wooden case.

3. Shipping: By sea, By air.

By sea: if customer not urgently the machine, we advice by sea, even though by sea took time is long, but by sea reduce much money about the freight, and it is good for customer if the machine is heavy and big size.

By air: it is faster than by sea, but its freight is higher much than by sea, so this kind of type always suggest for light, small size and urgently demand machine.

Pre-sale service

1.Related machines’s technical parameter will be supplied to customer.

2.According to customer’s factory size, factory layout can be provided in advance.

3. According to customer’s material cost, general formulation can be prepared well.

4.Special machine can be supplied as customer’s request.

5.Professional Advice about Market, machines, processing , materials, packing can be supplied

6. Suggesting professional ship agent or helping book ship as customer request.

After sale service :

1.Allocation chart as the buyer’s request will be supplied.

2.Operation manual will be supplied after shipment.

3.One year warrantee, life time maintenance with cost price.

4.Free easy broken spare parts will be sent with container .

5.First installation can be done by engineer.

6.Training workers in customer’s factory.