- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V, 380V, 3P, 50/60Hz

-

Dimension(L*W*H):

-

non-standard

-

Weight (T):

-

3 T

-

Power (kW):

-

35-180

-

Item:

-

pit/well type gas steel plasma nitriding furnace

-

Heat method:

-

Resistance Furnace

-

Loading capacity:

-

non-standard

-

Rated Temperature:

-

1200℃

-

Application:

-

annealing,tempering,nitriding, quenching and so on

-

Power:

-

35-180KW

-

Working size:

-

Customizable

-

Temperature control:

-

PID

-

Suitable Metal:

-

Stainless steel, copper etc

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Marketing Type:

-

Hot Product 2023

-

Brand Name:

-

SMKJ

-

Voltage:

-

380V, 380V, 3P, 50/60Hz

-

Dimension(L*W*H):

-

non-standard

-

Weight (T):

-

3 T

-

Power (kW):

-

35-180

-

Item:

-

pit/well type gas steel plasma nitriding furnace

-

Heat method:

-

Resistance Furnace

-

Loading capacity:

-

non-standard

-

Rated Temperature:

-

1200℃

-

Application:

-

annealing,tempering,nitriding, quenching and so on

-

Power:

-

35-180KW

-

Working size:

-

Customizable

-

Temperature control:

-

PID

-

Suitable Metal:

-

Stainless steel, copper etc

Products Description

pit/well type gas steel plasma nitriding furnace

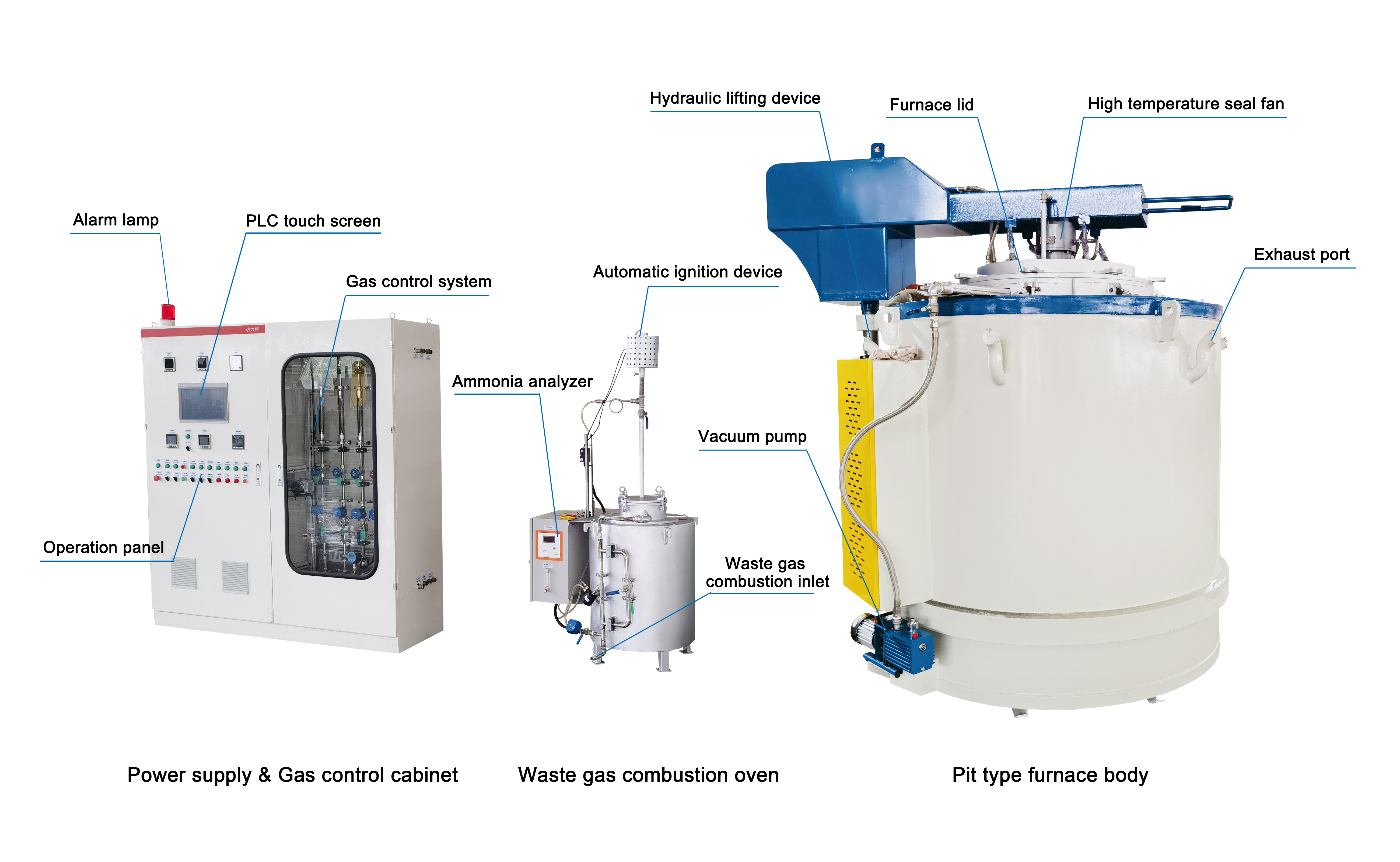

Structure display

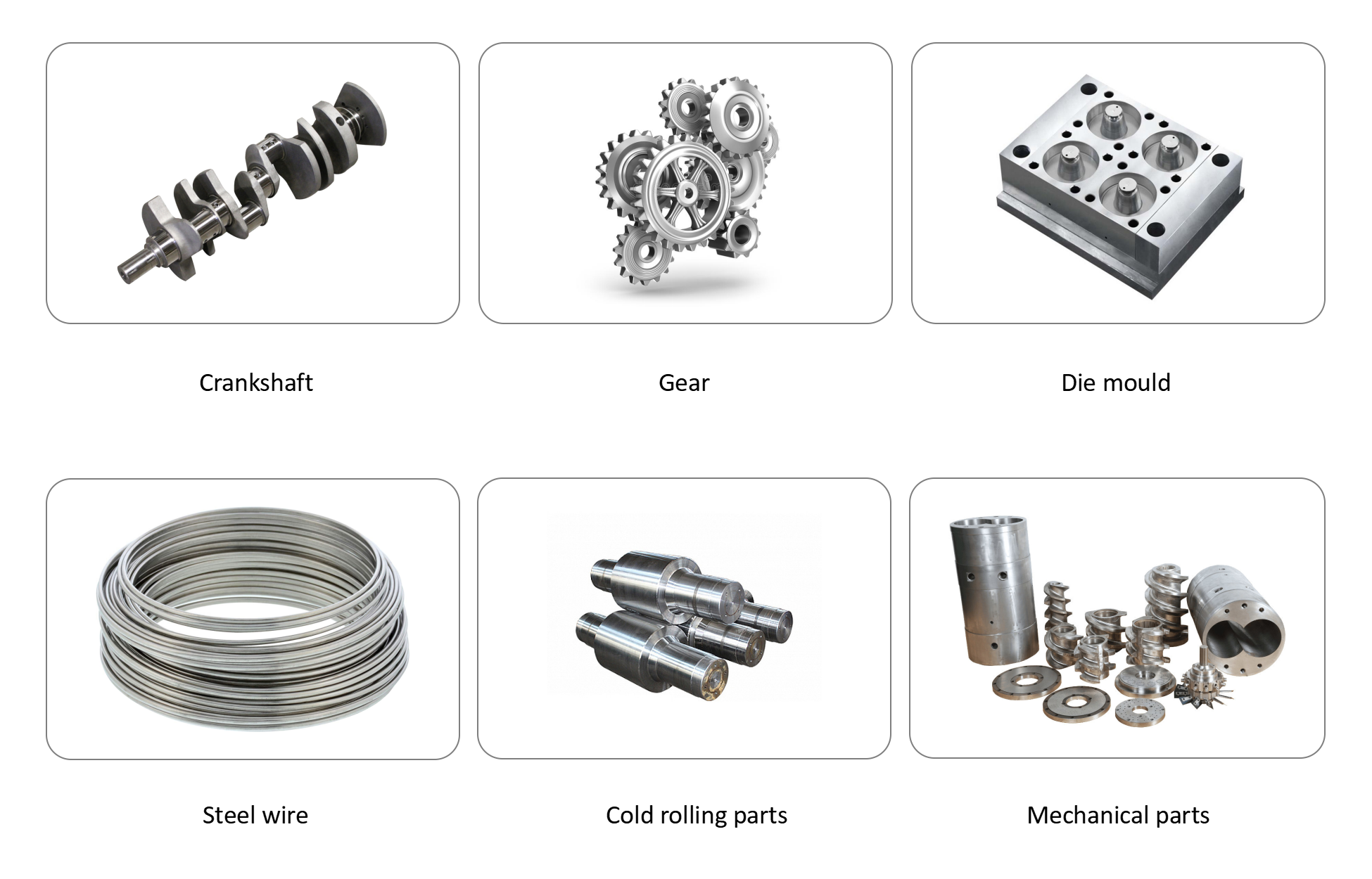

Application

This furnace is suitable for gas carburizing/nitriding treatment of various of die mould(especially suitable for H13), measuring tool,

cutting tool (such as: high speed steel cutter) and so on, crankshaft, gear, cylinder liner, mechanical parts and wear-resistant parts heat treatment.

cutting tool (such as: high speed steel cutter) and so on, crankshaft, gear, cylinder liner, mechanical parts and wear-resistant parts heat treatment.

Product Paramenters

|

Model

|

Voltage (V)

|

Power (KW)

|

Temperature (℃)

|

Working size (mm)

|

|

RJ3-25-6

|

380 / 3P

|

25

|

650

|

φ400*500

|

|

RJ3-35-6

|

380 / 3P

|

35

|

650

|

φ500*650

|

|

RJ3-55-6

|

380 / 3P

|

55

|

650

|

φ700*900

|

|

RJ3-75-6

|

380 / 3P

|

75

|

650

|

φ950*1200

|

|

RQ3-25-9

|

380 / 3P

|

25

|

950

|

φ300*450

|

|

RQ3-35-9

|

380 / 3P

|

35

|

950

|

φ300*600

|

|

RQ3-60-9

|

380 / 3P

|

60

|

950

|

φ450*600

|

|

RQ3-75-9

|

380 / 3P

|

75

|

950

|

φ450*900

|

|

RQ3-90-9

|

380 / 3P

|

90

|

950

|

φ600*900

|

|

RQ3-105-9

|

380 / 3P

|

105

|

950

|

φ600*1200

|

Product Details

Furnace body

The furnace body frame is welded with high-quality national standard profile steel and Q235 steel plate, with a firm and reliable structure, and all welds are uniform and smooth, without defects such as pores, inclusions, and lack of fusion. The overall strength is high, not easy to deform, and the appearance is flat and smooth.

Furnace lining

Made of Japan ISOLITE high temperature white cotton structure. Precompression treatment shall be conducted again before installation of the fiber folding block. The structure is fixed to a folded block with anchors, and has low thermal conductivity, excellent chemical stability, thermal stability, excellent strength and corrosion resistance..

Muffle tank

Made of SUS316 stainless steel with a thickness of 8mm. A corrugated molding machine is used to press it into a corrugated shape to improve the strength and expansion performance of the muffle tank. The inner layer of the muffle tank is welded by argon arc welding, and the weld seam is dense and free of pores.

Furnace cover

Made of heat resistant steel SUS316, δ 8mm. The bottom adopts a head type structure, and the butterfly shaped head is formed by back pressure.

The furnace cover adopts hydraulic lifting.

Cooling fan

Equipped with high quality air blower, the air volume is strong, cooling speed is very fast, greatly reducing the baking time.

After the preset process is completed, t

he system will automatically open the blower for cooling.

Electric control cabinet

It is equipped with temperature control system,

has functions such as PID automatic control, holding time setting function, setting time display, remaining holding time display, multi segment programming system and security alarm system:.

Customer On-site

Feature

2), Adopt the energy-saving furnace lining which can make fast temperature rising but saving more than 20% of energy compare with old product.

3), Large fan installed and multiple heating zone controling for improving the temperature uniformity.

4), The control system can be equipped with normal control instrument or instrument with micro-processor program control according to actual need.

5), The Protective atmosphere can be special fed into the furnace to realize little-oxidizing heating if your need.

6), Each product is installed with safety interlock and over-temperature device to provide reliable and safe operation and use.

Packaging & Shipping

Our services

I. Commissioned from the furnace after delivery, into the warranty period, the warranty period of two years.Regardless of the warranty period or warranty period, the furnace, such as failure, received a notice, we are committed to 36 hours to send to the scene to deal with.

II. In the warranty period by our cause failure, we carried out unconditional maintenance and replacement.Due to other causes ofthe failure, we only charge the cost of paid maintenance

III. After the warranty period, we will, as always, do a good job after-sales service, so that users no worries.

I. Commissioned from the furnace after delivery, into the warranty period, the warranty period of two years.Regardless of the warranty period or warranty period, the furnace, such as failure, received a notice, we are committed to 36 hours to send to the scene to deal with.

II. In the warranty period by our cause failure, we carried out unconditional maintenance and replacement.Due to other causes ofthe failure, we only charge the cost of paid maintenance

III. After the warranty period, we will, as always, do a good job after-sales service, so that users no worries.

Customer Photos

FAQ

1. What is your advantage compared to others?

First, we provided turnkey solution, Cost-effective, highly efficient, durable, and easy-to-operate machine is what we deliver.Second, we have a Strict Quality Control System, Before Being dispatched from our factory all of our equipment will undergo a series of strict test, including the appearance quality test, voltage electrical test, aging test also the package strength checking.

2. If our machine meets fault, how could you help us to solve it?

For failures caused by using process, we will send our aftersales engineer to discuss with you, and you should provide the video of how the machine is broken, we will find out which part of the machine is broken, and then we will send you the broken part By DHL.

3. What is your warranty?

Our warranty period comes from the machine begin to run normally and we will provide the whole life technology support to you for free.

All products sold by COOLDO In the warranty period, we will provide you the spare parts for free. Our engineer will help you do the aftersales through our remote control system. When out of one year warranty time, we will provide the spare parts with the cost price for the whole machine lifetime.

First, we provided turnkey solution, Cost-effective, highly efficient, durable, and easy-to-operate machine is what we deliver.Second, we have a Strict Quality Control System, Before Being dispatched from our factory all of our equipment will undergo a series of strict test, including the appearance quality test, voltage electrical test, aging test also the package strength checking.

2. If our machine meets fault, how could you help us to solve it?

For failures caused by using process, we will send our aftersales engineer to discuss with you, and you should provide the video of how the machine is broken, we will find out which part of the machine is broken, and then we will send you the broken part By DHL.

3. What is your warranty?

Our warranty period comes from the machine begin to run normally and we will provide the whole life technology support to you for free.

All products sold by COOLDO In the warranty period, we will provide you the spare parts for free. Our engineer will help you do the aftersales through our remote control system. When out of one year warranty time, we will provide the spare parts with the cost price for the whole machine lifetime.

Hot Searches