Qingdao Pingte Machinery Equipmate Co., Ltd.is a modern enterprise integrating R&D, production, agency and sales. The company has always been "Provide to customers with efficient and high-quality printing machinery" as their mission, focusing on the printing

industry machinery production, and constantly improve their service levels.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

PT

-

Dimensions(L*W*H):

-

195*98*78cm

-

Weight:

-

5 KG

-

Platen Size:

-

customize

-

Product name:

-

Nomex Felt Belt Blanket

-

Application:

-

roller heat press machine

-

Keywords:

-

Nomex Endless Felt

-

Usage on:

-

T-shirt.fabric. Cloth

-

MOQ:

-

1 Set Sublimation Heat Press Machine

-

Printing area:

-

any size

-

Time range:

-

0-999Sec

-

Temperature Range:

-

180℃-280℃

-

Material:

-

DuPont's 100% Nomex

-

Lead time:

-

3 days

Quick Details

-

Condition:

-

New

-

Plate Type:

-

Flatbed Printer

-

Color & Page:

-

Multicolor

-

Voltage:

-

220V

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

PT

-

Dimensions(L*W*H):

-

195*98*78cm

-

Weight:

-

5 KG

-

Platen Size:

-

customize

-

Product name:

-

Nomex Felt Belt Blanket

-

Application:

-

roller heat press machine

-

Keywords:

-

Nomex Endless Felt

-

Usage on:

-

T-shirt.fabric. Cloth

-

MOQ:

-

1 Set Sublimation Heat Press Machine

-

Printing area:

-

any size

-

Time range:

-

0-999Sec

-

Temperature Range:

-

180℃-280℃

-

Material:

-

DuPont's 100% Nomex

-

Lead time:

-

3 days

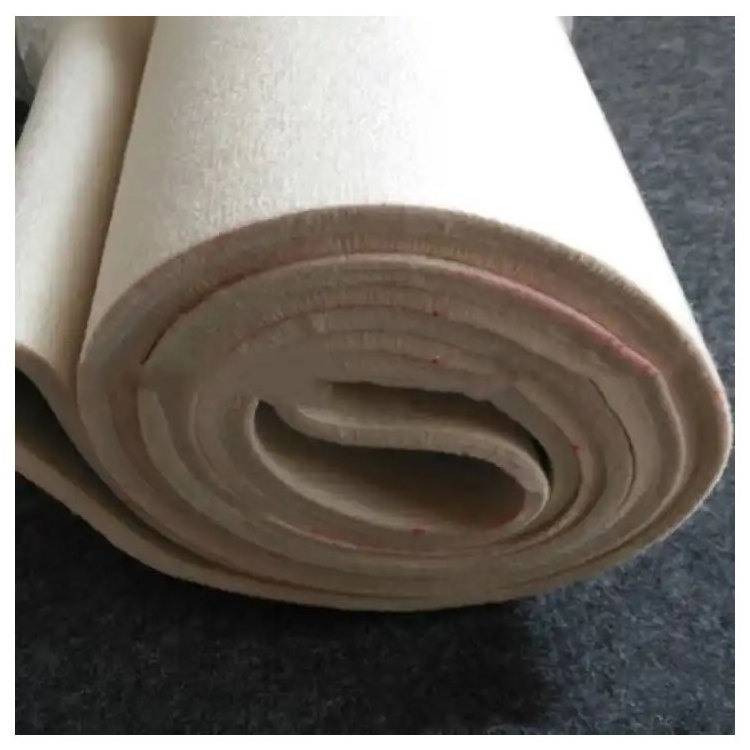

Heat transfer printing felt blanket queen size nomex felt belt for paper making machine

Products Description

|

Item Name

|

100% Nomex Endless Felt

|

|

HS Code

|

59100000

|

|

Color

|

White

|

|

Material

|

DuPont's 100% Nomex

|

|

Size

|

Any size is ok

|

|

Density

|

1200g/m2- 6000g/m2

|

|

Working temperature

|

180 -280

|

|

Sample

|

Freely

|

|

Thickness

|

8mm-10mm

|

|

Packing

|

Non-woven bag

|

|

Lead Time

|

3days

|

|

MOQ

|

1 Roll

|

Our felt is made of 100% Nomex fiber which is imported from DuPont USA, it is one of the import part of the Roller Heat Press Machine, we choose the best felt in China, and use our 10years experience to guide you install and maintain the felt.

Installation problems of thermal transfer machine blankets:

The thermal transfer machine blankets are generally adjusted before they leave the factory, because the thermal transfer machine blankets work at a high temperature of 250 C, and the cold machine and thermal transfer machine blankets experience thermal expansion and contraction, so when the transfer is just started If there is a deviation, please use the following methods to solve it.

1. In normal transfer, the blanket moves to the left and can be driven in the reverse direction. At this time, the blanket moves to the right and stops on the side of the big drum. Tighten the adjustment screw at the left end of the lower tension shaft ``4'' and loosen it properly. Just lower the adjusting screw at the right end of the tension shaft ``4''.

2. After using the above method to correct the deviation, if the blanket is still moving to the left at this time, please turn the high-speed joint screw at the right end of the front upper tension shaft ``1'' and push it forward by 5-8mm.

3. Move the blanket to the right, and you can drive in the opposite direction. At this time, the blanket will move to the left and stop on the side of the big tube. Tighten the adjusting screw at the right end of the rear lower tension shaft ``4'', and loosen the rear lower tension shaft properly. The adjustment screw at the left end of 4" is enough.

4. After using the above method to correct the deviation, if the blanket is still going to the right at this time, please turn the adjustment screw at the left end of the front upper tension shaft "4" and push it forward by 5-8mm.

Precautions

1. During normal transfer, if the content that needs to be transferred is not ready, you can lower the speed appropriately. It is best not to stop, so as to avoid too much color deviation, and do not reverse to avoid shadows.

2. After the machine is used, it should still be in a rotating state, because the temperature is still very high after it is used, it may damage the blanket after it stops, and reduce the service life of the blanket, and the temperature must be kept within a safe range. Turn off the main power supply.

3. If there is a power outage during transfer, turn the hand wheel so that the blanket can be completely separated from the roller. The most important aspect is to reduce the temperature. It is estimated that the rotation can be stopped after it drops to a safe range, but the main power supply must be turned off. So as not to know when you call.

4. When the machine is running at high speed, the positive and negative gears cannot be interchanged to avoid burning the fuse. The forward and reverse gears can only be interchanged after turning down the speed.

The thermal transfer machine blankets are generally adjusted before they leave the factory, because the thermal transfer machine blankets work at a high temperature of 250 C, and the cold machine and thermal transfer machine blankets experience thermal expansion and contraction, so when the transfer is just started If there is a deviation, please use the following methods to solve it.

1. In normal transfer, the blanket moves to the left and can be driven in the reverse direction. At this time, the blanket moves to the right and stops on the side of the big drum. Tighten the adjustment screw at the left end of the lower tension shaft ``4'' and loosen it properly. Just lower the adjusting screw at the right end of the tension shaft ``4''.

2. After using the above method to correct the deviation, if the blanket is still moving to the left at this time, please turn the high-speed joint screw at the right end of the front upper tension shaft ``1'' and push it forward by 5-8mm.

3. Move the blanket to the right, and you can drive in the opposite direction. At this time, the blanket will move to the left and stop on the side of the big tube. Tighten the adjusting screw at the right end of the rear lower tension shaft ``4'', and loosen the rear lower tension shaft properly. The adjustment screw at the left end of 4" is enough.

4. After using the above method to correct the deviation, if the blanket is still going to the right at this time, please turn the adjustment screw at the left end of the front upper tension shaft "4" and push it forward by 5-8mm.

Precautions

1. During normal transfer, if the content that needs to be transferred is not ready, you can lower the speed appropriately. It is best not to stop, so as to avoid too much color deviation, and do not reverse to avoid shadows.

2. After the machine is used, it should still be in a rotating state, because the temperature is still very high after it is used, it may damage the blanket after it stops, and reduce the service life of the blanket, and the temperature must be kept within a safe range. Turn off the main power supply.

3. If there is a power outage during transfer, turn the hand wheel so that the blanket can be completely separated from the roller. The most important aspect is to reduce the temperature. It is estimated that the rotation can be stopped after it drops to a safe range, but the main power supply must be turned off. So as not to know when you call.

4. When the machine is running at high speed, the positive and negative gears cannot be interchanged to avoid burning the fuse. The forward and reverse gears can only be interchanged after turning down the speed.

Since in 2005, it has established good relations with many domestic and foreign enterprises. The products sell well all over the country and are exported to Europe, America, Southeast Asia, Middle East, Africa and other regions. They are highly trusted and highly praised by domestic and foreign customers. The company has advanced production and professional technology, R & D team, so that our products can be favored by our customers. After years of development, the company's main products are screen printing machine(oval printing machine, rotary printing machine and so on ), roller heat transfer machine, T-shirt folding machine, Digital printing machine, heat press machine,

01

Are You a Factory Or a Trading Company?

Factory

02

Do You Accept Customize Machine?

Please communicate with us salesperson at first, we can customize machine on us developing ability.

03

What's The Payment Item?

We usually do 50% T/T as deposit, 50% balance payment before shipment. Cash payment, L/C also can accept on old customer.

04

Do You Have Any Certificate?

We have CE certificate and original certificate if you need.

05

What's Your Warranty?

We supply one-year warranty and full time spare parts supplying after warranty.

Hot Searches