1. 100% virgin raw material guaranteed products quality

2.Advanced production equipment/test equipment (With HIP sintering)

3. compititive price and fast delivery

4. products with high performance:high wear-resistance ,toughness and corrosion resistance

5. customization is avaliable

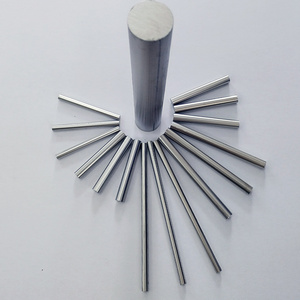

Application of our cemented carbide rod

1.PCB drills , drills , end mills and reamers , mold punches , core pins and hole drilling tools

2.Cutting tools for material: aluminum alloy ,cast iron , stainless steel, refractory alloy steel, nickel-based alloy , titanium

alloy and nonferrous.

3. Used for wear parts

- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Metallic

-

Product name:

-

Tungsten Carbide Rod

-

Material:

-

WC+CO

-

Shape:

-

Round Tungsten Bar Rod

-

Surface:

-

Polished

-

Keywords:

-

Tungsten Rod

-

Usage:

-

Tool Part

-

Type:

-

Power Tool Parts

-

Grade:

-

YG8/YG6/YG6X/YG15

-

Advantage:

-

High Density

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

M&A

-

Model Number:

-

bar,rod,non-standard

-

Application:

-

Metallic

-

Product name:

-

Tungsten Carbide Rod

-

Material:

-

WC+CO

-

Shape:

-

Round Tungsten Bar Rod

-

Surface:

-

Polished

-

Keywords:

-

Tungsten Rod

-

Usage:

-

Tool Part

-

Type:

-

Power Tool Parts

-

Grade:

-

YG8/YG6/YG6X/YG15

-

Advantage:

-

High Density

Product Description

Overview

Tungsten heavy alloys illustrate the advantages of microencapsulated powders. A brief background of this alloy system follows.

Tungsten heavy alloys generally are refractory metal, which have two-phase composites consisting of W-Ni- Fe or W-Ni- Cu or even W-Ni-Cu-Fe, some tungsten alloy is added Co、Mo、Cr, etc. They have very high melting point and have a density twice that of steel and are more than 50% heavier than lead. Tungsten content in conventional heavy alloys varies from 90 to 98 weight percent and is the reason for their high density (between 16.5 and 18.75 g/cc). Nickel, iron and copper serve as a binder matrix, which holds the brittle tungsten grains together and which makes the alloys ductile and easy to machine. Nickel-iron is the most popular additive, in a ratio of 7Ni:3Fe or 8Ni:2Fe (weight ratio). The conventional processing route for tungsten heavy alloys includes mixing the desired amount of elemental powders, followed by cold pressing and liquid phase sintering to almost full density. The matrix alloy

melts and takes some tungsten into solution during liquid phase processing, resulting in a microstructure through which large tungsten grains (20–60µm) are dispersed in the matrix alloy. The as-sintered material often is subjected to thermo mechanical processing by swaging and aging, which results in increased strength and hardness in the heavy alloys.

Tungsten heavy alloys generally are refractory metal, which have two-phase composites consisting of W-Ni- Fe or W-Ni- Cu or even W-Ni-Cu-Fe, some tungsten alloy is added Co、Mo、Cr, etc. They have very high melting point and have a density twice that of steel and are more than 50% heavier than lead. Tungsten content in conventional heavy alloys varies from 90 to 98 weight percent and is the reason for their high density (between 16.5 and 18.75 g/cc). Nickel, iron and copper serve as a binder matrix, which holds the brittle tungsten grains together and which makes the alloys ductile and easy to machine. Nickel-iron is the most popular additive, in a ratio of 7Ni:3Fe or 8Ni:2Fe (weight ratio). The conventional processing route for tungsten heavy alloys includes mixing the desired amount of elemental powders, followed by cold pressing and liquid phase sintering to almost full density. The matrix alloy

melts and takes some tungsten into solution during liquid phase processing, resulting in a microstructure through which large tungsten grains (20–60µm) are dispersed in the matrix alloy. The as-sintered material often is subjected to thermo mechanical processing by swaging and aging, which results in increased strength and hardness in the heavy alloys.

Application

Apply for apparatus and instrument for medical, military and airspace industries. The majority of current uses for WHAs (tungsten heavy alloys) are best satisfied with the W-Ni-Fe system. Alloys such as 93W-4.9Ni-2.lFe and 95W-4Ni-lFe represent common compositions. The addition of cobalt to a W-Ni-Fe alloy is a common approach for slight enhancement of both strength and ductility. The presence of cobalt within the alloy provides solid-solution strengthening of the binder and slightly enhanced tungsten-matrix interfacial strength. Cobalt additions of 5 to 15% of the nominal binder weight fraction arc most common.

|

|

|

Specification

|

Grade

|

DENS

g/cm3

|

Co%

|

Granularity

|

HRA

|

Hv10

|

kgf/mm2

|

|

YH08

|

14.95

|

6

|

1.0

|

92.5

|

1700

|

240

|

|

YH06F

|

14.90

|

7

|

0.8

|

93.5

|

1820

|

240

|

|

YH07F

|

14.70

|

8

|

0.8

|

92.5

|

1750

|

250

|

|

YH10F

|

14.45

|

10

|

0.8

|

91.8

|

1630

|

350

|

|

YH12F

|

14.25

|

12

|

0.6

|

92.4

|

1700

|

300

|

|

YH13F

|

14.10

|

13

|

0.8

|

90.5

|

1550

|

350

|

|

GH12S

|

14.05

|

12

|

1-3

|

89.5

|

1400

|

330

|

|

YH20

|

14.90

|

7

|

1-3

|

91.0

|

1520

|

280

|

|

YH15

|

14.00

|

15

|

3.0

|

87.5

|

1150

|

350

|

|

YH25

|

14.75

|

8

|

3.0

|

90.0

|

1450

|

290

|

|

TH30

|

14.60

|

9

|

1-3

|

91.0

|

1500

|

300

|

|

YH40

|

14.65

|

10

|

3.0

|

89.5

|

1360

|

320

|

|

GH05

|

14.40

|

12

|

3.0

|

88.5

|

1250

|

330

|

|

GH10

|

14.40

|

12

|

3.0

|

87.5

|

1150

|

330

|

|

GH20

|

14.00

|

15

|

10

|

86.0

|

1050

|

350

|

|

GH30

|

13.80

|

18

|

10.0

|

85.0

|

1000

|

320

|

|

GH40

|

13.60

|

20

|

10.0

|

84.5

|

950

|

310

|

|

GH50N

|

13.40

|

22

|

10.0

|

83.5

|

900

|

290

|

|

GH55S

|

13.15

|

24

|

6-10

|

80.5

|

800

|

220

|

|

GH06N

|

14.70

|

5

|

1.0

|

91.5

|

1650

|

280

|

|

LD01

|

13.90

|

15

|

3-10

|

87.0

|

1120

|

380

|

|

LD02

|

13.35

|

20

|

10

|

84.5

|

960

|

310

|

|

LD03

|

13.25

|

25

|

3-10

|

86.0

|

1000

|

280

|

Hot Searches