- Product Details

- {{item.text}}

Quick Details

-

Return Force (kN):

-

70 kN

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

KELAI

-

Year:

-

2022

-

Voltage:

-

380V according to your local voltage

-

Dimension(L*W*H):

-

3100*1350*4000

-

Weight (T):

-

12 T

-

Model Number:

-

YH27-200T

-

Motor Power (kw):

-

18.5 kw

-

After-sales Service Provided:

-

Two Years After-sales Service

-

Function:

-

Hot Forming Press Machine

-

Type:

-

H-frame

-

Max Opening Height:

-

12000mm

-

Ejecting stroke:

-

170mm

-

slide stroke:

-

800mm

-

down speed:

-

200mm/s

-

working speed:

-

1-6mm/s

-

opening mould speed:

-

2-25mm/s

-

table size:

-

900*900

Quick Details

-

Machine Type:

-

H Frame Hydraulic Press

-

Slide Stroke (mm):

-

700

-

Ejector Force (kN):

-

400

-

Return Force (kN):

-

70 kN

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

KELAI

-

Year:

-

2022

-

Voltage:

-

380V according to your local voltage

-

Dimension(L*W*H):

-

3100*1350*4000

-

Weight (T):

-

12 T

-

Model Number:

-

YH27-200T

-

Motor Power (kw):

-

18.5 kw

-

After-sales Service Provided:

-

Two Years After-sales Service

-

Function:

-

Hot Forming Press Machine

-

Type:

-

H-frame

-

Max Opening Height:

-

12000mm

-

Ejecting stroke:

-

170mm

-

slide stroke:

-

800mm

-

down speed:

-

200mm/s

-

working speed:

-

1-6mm/s

-

opening mould speed:

-

2-25mm/s

-

table size:

-

900*900

Products Description

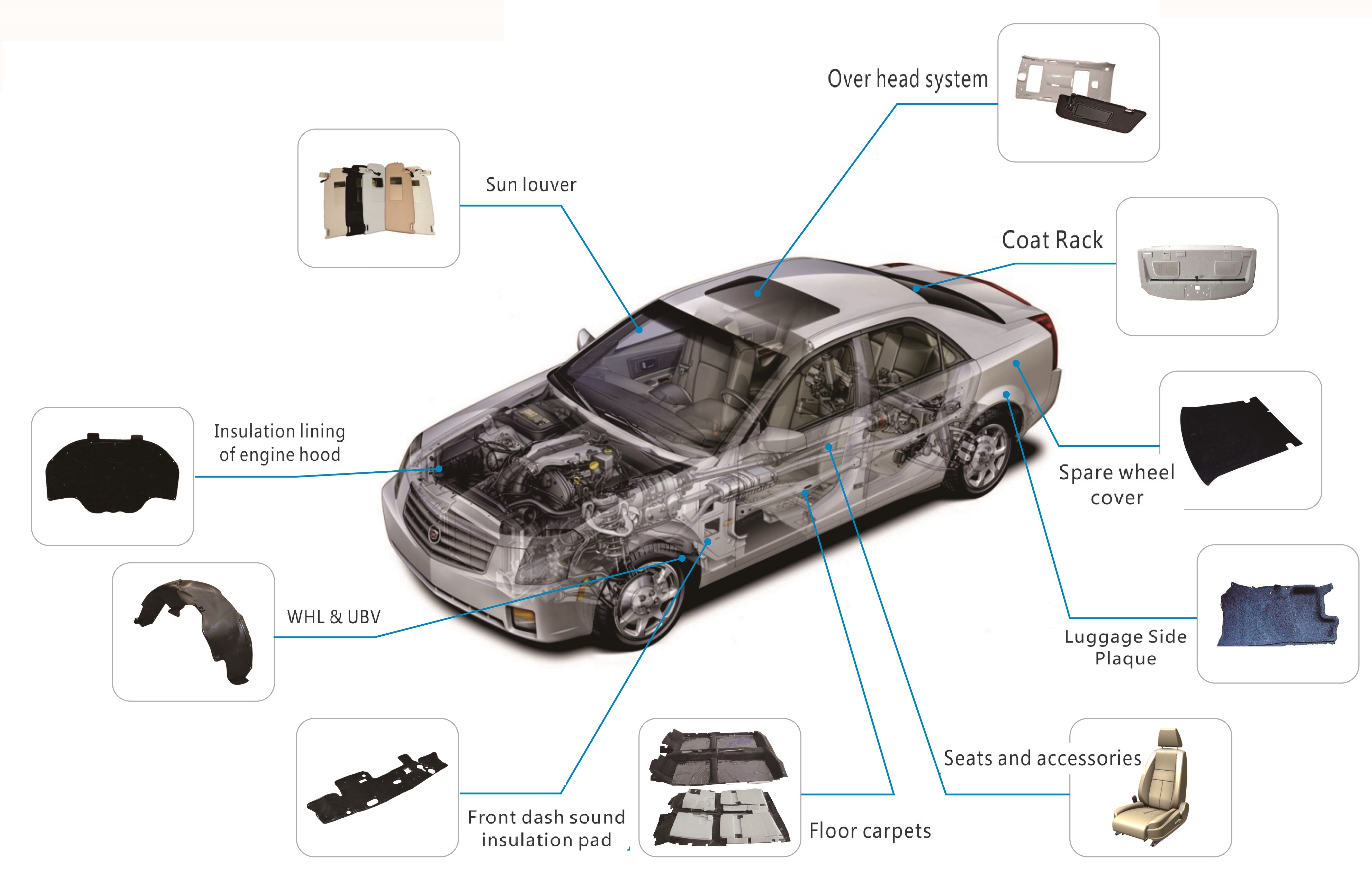

1. new generation numerical control hydraulic press, frame structure eight face guide structure. Applicable technology,

assembly, embossing, molding, punching, cutting edge.

2. suitable for automobile, motor, hardware, aviation, electronics, electrical appliances and other medium-sized parts.

3. servo motor combined with high precision oil pump to drive the hydraulic cylinder.

4. PLC programming, touch screen display, control.

assembly, embossing, molding, punching, cutting edge.

2. suitable for automobile, motor, hardware, aviation, electronics, electrical appliances and other medium-sized parts.

3. servo motor combined with high precision oil pump to drive the hydraulic cylinder.

4. PLC programming, touch screen display, control.

|

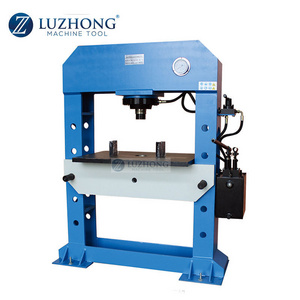

H Frame Hydraulic Press

Optional

|

|

|

|

#low noise, noise can be controlled at about 60 decibels.

|

|

|

|

#Working position, speed and pressure can be adjusted steplessly.

|

|

|

|

#High efficiency and energy saving, energy consumption is 30% -50% less than ordinary motors.

|

|

|

|

#Quick response, high pressure and position repeatability

|

|

|

|

#High efficiency, multiple protections inside, extremely low failure rate.

|

|

|

|

#12 hours of continuous work does not require cooling oil temperature.

|

|

|

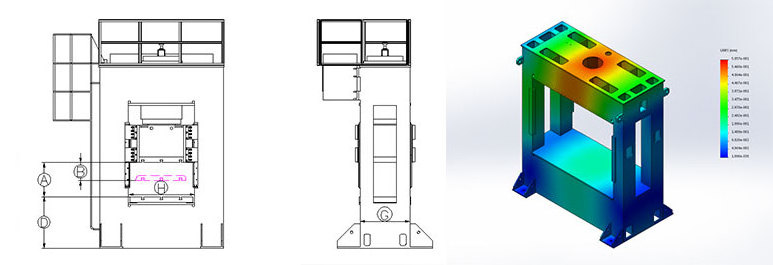

Size Information

|

Description

|

Unit

|

100T

|

200T

|

315T

|

500T

|

630T

|

1000T

|

1500T

|

2000T

|

|

Slide Stroke

|

mm

|

600

|

800

|

800

|

1200

|

1200

|

1600

|

1600

|

2000

|

|

Opening Height

|

mm

|

900

|

1200

|

1200

|

1600

|

1600

|

2000

|

2000

|

2500

|

|

Ejecting stroke

|

mm

|

150

|

170

|

180

|

180

|

180

|

200

|

220

|

250

|

|

Preload Pressure

|

KN

|

315

|

630

|

1000

|

1500

|

2000

|

3150

|

5000

|

6300

|

|

Working speed

|

mm/s

|

1-6

|

1-6

|

1-6

|

1-6

|

1-6

|

0.5-5

|

0.5-5

|

0.5-5

|

|

Return speed

|

mm/s

|

100

|

100

|

100

|

150

|

150

|

200

|

200

|

200

|

|

Master Pump Speed

|

KW

|

11

|

18.5

|

30

|

45

|

75

|

110

|

180

|

230

|

|

Weight

|

T

|

4.2

|

12

|

22.5

|

43.5

|

56

|

112

|

162

|

222

|

Details Images

Factories improve efficiency, equipment speeds are getting faster and faster, and the safety and reliability of equipment is the key! ! !

Automatic locking device for the safety rack of the middle slide block (the slide block returns to the upper limit to lock the rack to prevent the slide block from automatically falling)

The sliding block supports the safety bar (purpose: personnel enter the fuselage when installing the mold, to prevent the sliding block from accidentally falling, and to protect personal safety) (with a safety interlock device, the safety rod cannot be

pressurized in the fuselage, and the slider cannot go down , Can only be returned)

pressurized in the fuselage, and the slider cannot go down , Can only be returned)

Front and rear safety light curtain protection device (to prevent personnel from entering the dangerous area during equipment

operation, the light curtain protection slider automatically retracts) Four-corner safety emergency stop switch (to prevent

accidents, the four corners of the fuselage can stop the machine in time)

operation, the light curtain protection slider automatically retracts) Four-corner safety emergency stop switch (to prevent

accidents, the four corners of the fuselage can stop the machine in time)

Safety light curtain, emergency stop button, etc. are all controlled by safety relay interlocking, which is safe and reliable.

The hydraulic system adopts CE standards, with monitoring and redundancy

The left and right openable safety guardrails on the lower side of the fuselage, and the safety guardrail with the height of 1200mm on the top of the fuselage

Recommend Products

Hot Searches