- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

DY

-

Model Number:

-

NA

-

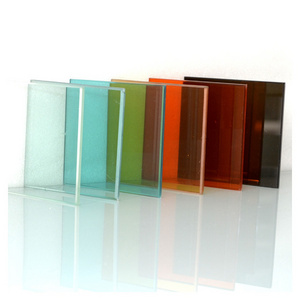

color:

-

clear, ultra clear, colored

-

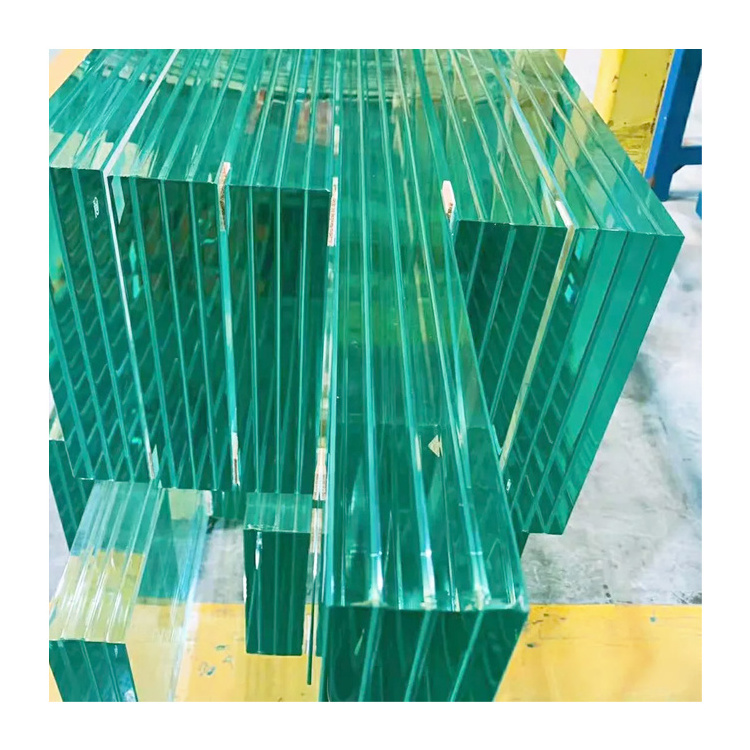

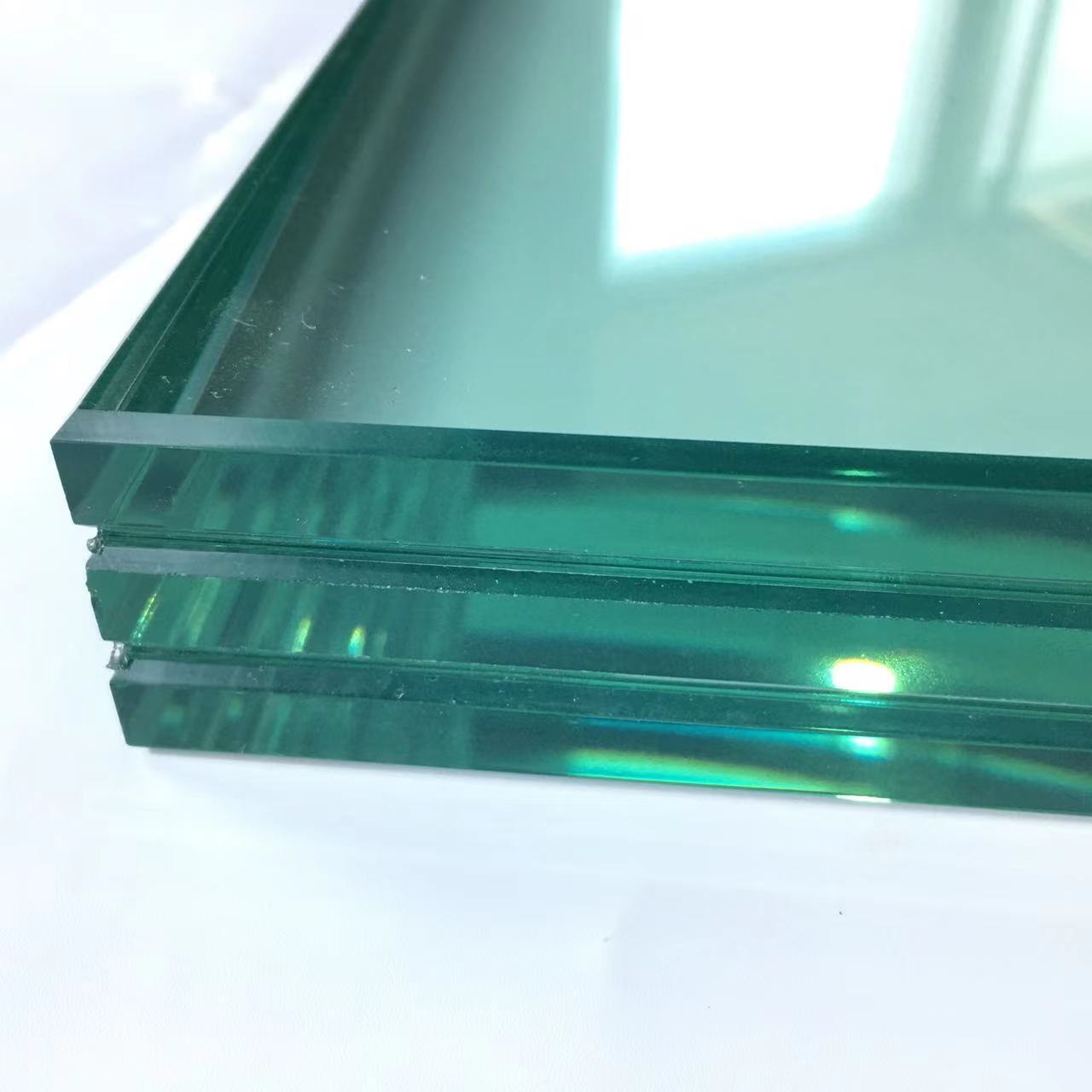

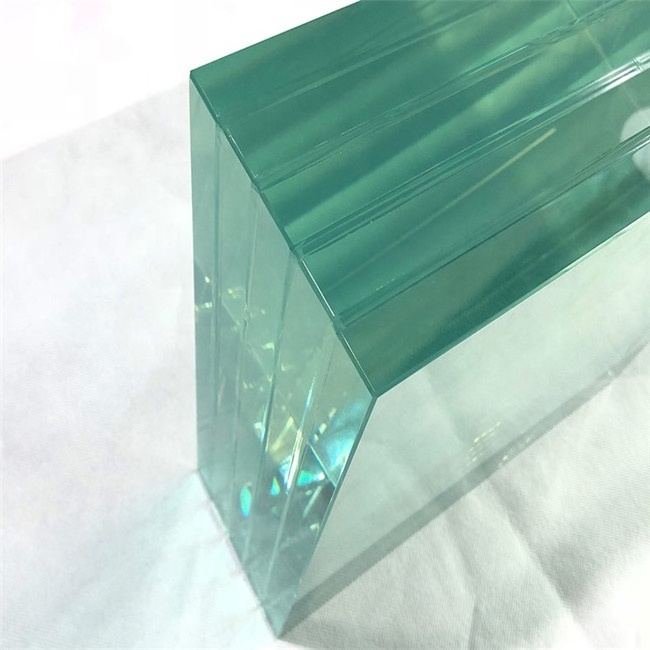

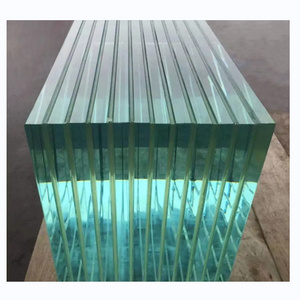

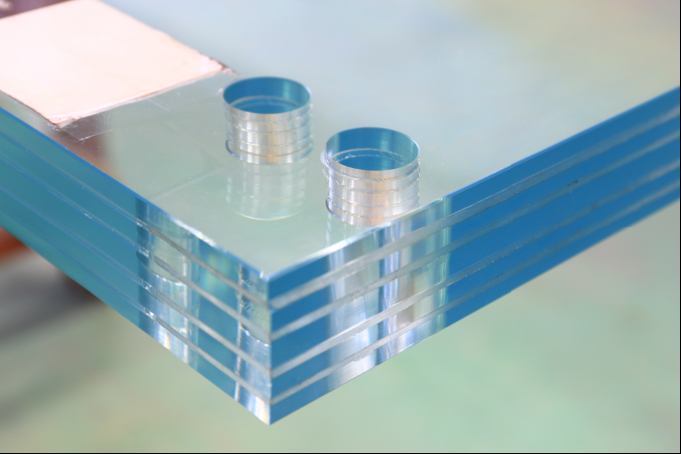

thickness:

-

10-89mm

-

processing:

-

tempered, laminated

-

application:

-

architectural glass

-

max. size:

-

3300x12500mm

-

certificate:

-

CE, ISO, ASTM

-

Packing:

-

Wooden Crate

-

Keywords:

-

bulletproof glass

-

Sample:

-

Within 7 Days

-

Edge:

-

Polished

Quick Details

-

Application:

-

Courtyard, Leisure Facilities, Supermarket, Farmhouse, Laundry, Workshop, Kitchen, School, Bathroom, Bedroom, Exterior, Dining, Warehouse, Home Office, Staircase, Outdoor, Living Room, Park, Wine Cellar, Office Building, Storage & Closet, Gym, Mall, Entry, Apartment, Sports Venues, Basement, Hospital, Villa, Hotel, Home Bar, Hall, Garage & Shed

-

Usage:

-

Industrial, Decoration, Greenhouse, Curtain Wall, Balustrades & Handrails, Bulletproof

-

Thickness:

-

3-25mm

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

DY

-

Model Number:

-

NA

-

color:

-

clear, ultra clear, colored

-

thickness:

-

10-89mm

-

processing:

-

tempered, laminated

-

application:

-

architectural glass

-

max. size:

-

3300x12500mm

-

certificate:

-

CE, ISO, ASTM

-

Packing:

-

Wooden Crate

-

Keywords:

-

bulletproof glass

-

Sample:

-

Within 7 Days

-

Edge:

-

Polished

Dayang laminated glass meets rigorous industry codes, including the American Society of Testing Materials standard for preventing forced entry (ASTM). Our laminated glass is customized to meet the requirements of any security application, providing the best options available.

Processing width of the bevel edge is 35mm

length 2440*2850mm, minimum radius 800mm;

Soft shaft bending section: height*arc

length 4200*2240mm, minimum radius 1000mm;

Hard shaft bending section: height*arc

length 2600*1200mm, minimum radius 450mm;

Q1: How to judge the quality of float glass?

A1: Flatness, transparency, colorless, impurities, bubbles, etc.

Q2: How to reduce the self-implosion?

A2: The high quality float method is used for hot dip treatment, edge treatment and proper stress intensity. Pay attention to avoid side collision of glass during installation.

Q3: Scope of use of toughened glass?

A3: Safety is not involved in some parts of the building, but it is necessary to install toughened glass to improve the compressive strength and explosion-proof capacity, and not to endanger the safety of the person.

Q4: When toughened glass is broken, is the grain smaller the better?

A4: No, the smaller the particle, the easier it is to explode.

Q5: Can toughened glass and semi-toughened glass be made into laminated glass?

A5: Can't. The national standard stipulates: the glass that stresses the difference cannot make laminated glass, because in use process, the pressure that two pieces of glass bears is different.

Q6: Whether the laminated glass can fire, can the sound insulation?

A6: No, the smaller the particle, the easier it is to explode.

Q7: How many uv low-e glass can reduce?

A7: It is not fireproof glass, but has certain fireproof ability, also can soundproof, laminated glass is inside whole sound wave frequency range, in control noise is very good.

Q8: Does the air in the insulating glass do not oxidize the membrane?

A8: No, because there is a molecular sieve in the insulating glass, and the molecular sieve always keeps the air dry, so the membrane is not oxidized.

Q9: How much ultraviolet radiation can low-e glass reduce?

A9: It can reduce uv by 14% compared to heat reflecting glass. That's a 25 percent reduction in uv radiation compared to white glass.