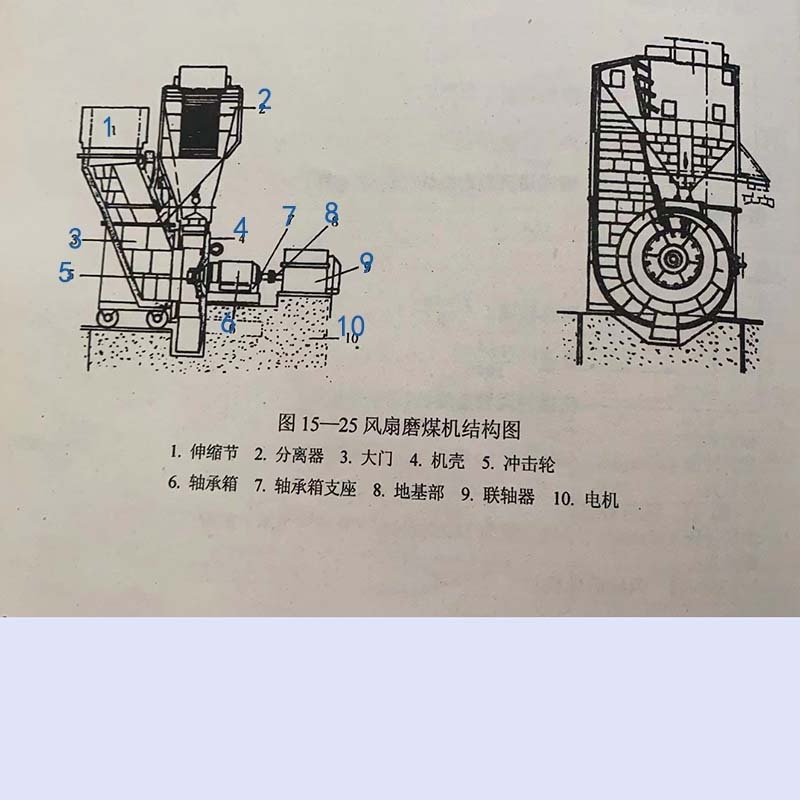

1. Expansion joint

2. Separator

3. The door

4. Case

5. Impact wheel

6. Bearing box

7. Bearing box bearing

8. Ground base

9. Coupling

10. Motor

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

VARIES

-

Weight:

-

80000 KG

-

Product name:

-

Stone Crushing Plant

-

Keyword:

-

Ball Mill

-

Name:

-

Crusher Stone Machine

-

The Machines classification:

-

Building Stone Production Line

-

Raw material:

-

Stones Rocks Ores

-

Usage:

-

Crushing Work

-

Function:

-

Mining Crusher Equipment

-

Processed Materials:

-

200 Kinds Materials(<300 Mpa)

-

Applicaton:

-

Stone Process

-

Crusher type:

-

Primary Coarse Jaw Crusher

Quick Details

-

Capacity(t/h):

-

25 t/h

-

Place of Origin:

-

China

-

Brand Name:

-

BYHI

-

Dimension(L*W*H):

-

VARIES

-

Weight:

-

80000 KG

-

Product name:

-

Stone Crushing Plant

-

Keyword:

-

Ball Mill

-

Name:

-

Crusher Stone Machine

-

The Machines classification:

-

Building Stone Production Line

-

Raw material:

-

Stones Rocks Ores

-

Usage:

-

Crushing Work

-

Function:

-

Mining Crusher Equipment

-

Processed Materials:

-

200 Kinds Materials(<300 Mpa)

-

Applicaton:

-

Stone Process

-

Crusher type:

-

Primary Coarse Jaw Crusher

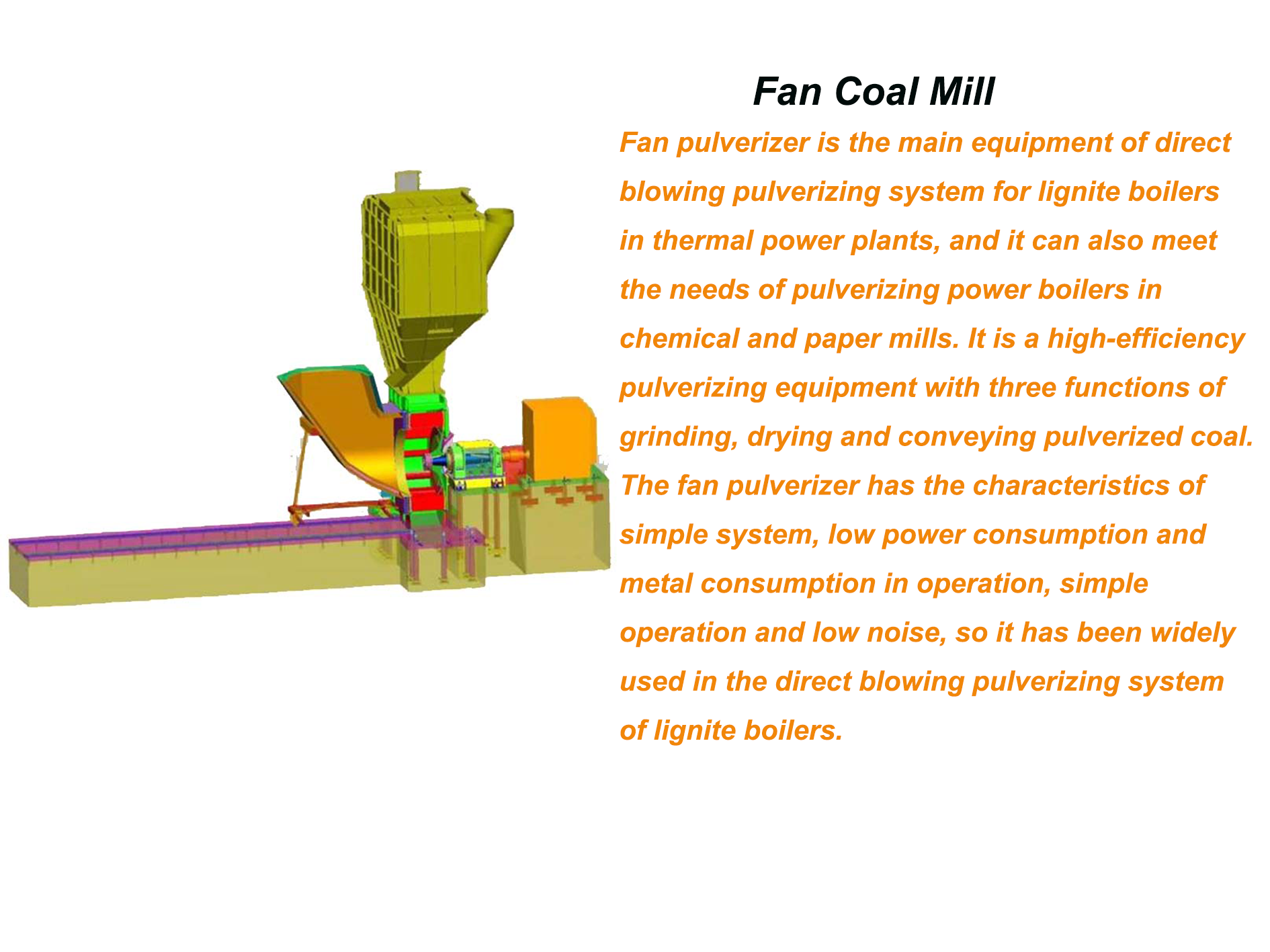

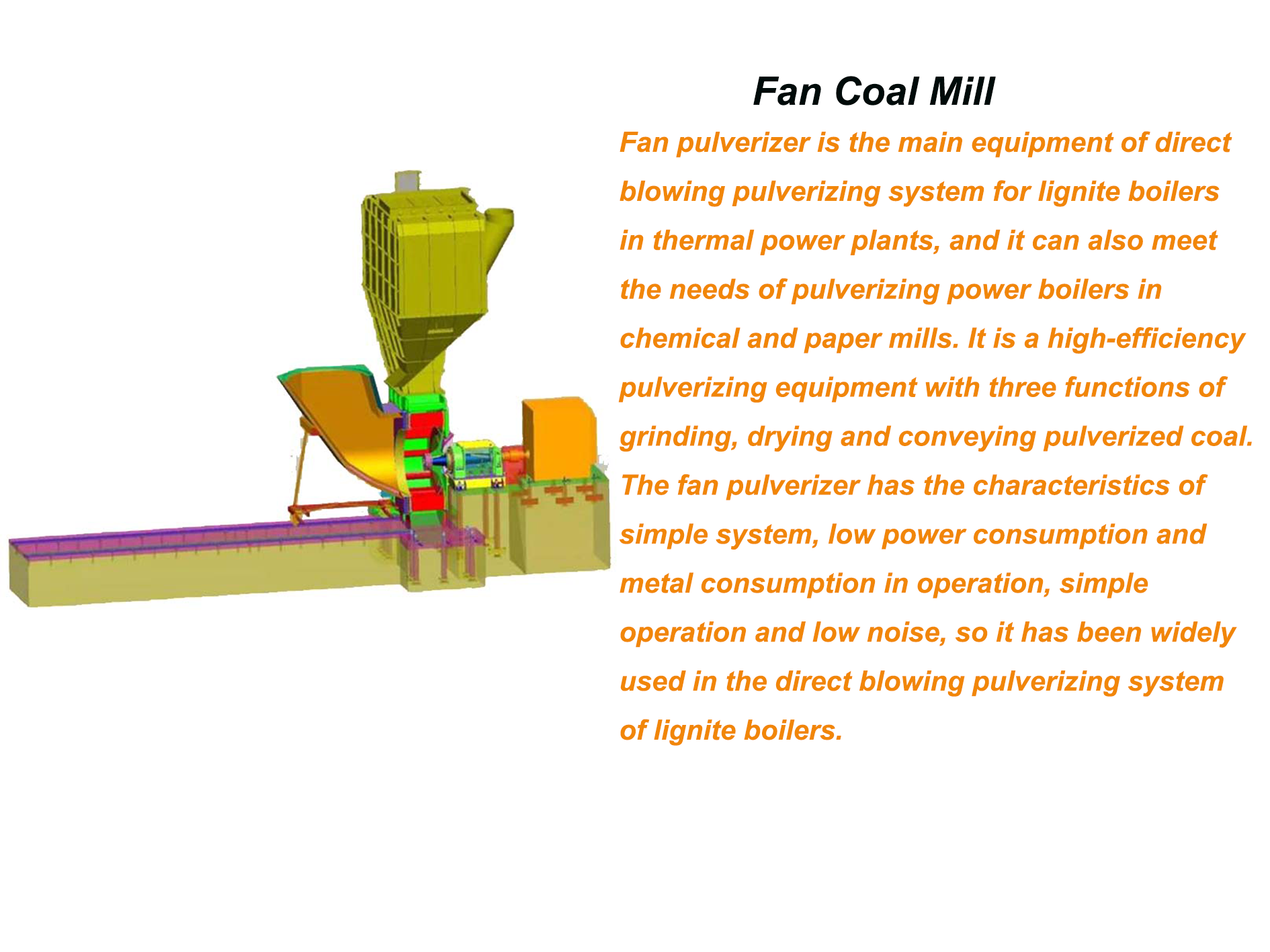

Products Description

Fan coal mill

Fan coal mill is the main equipment of lignite boiler direct blowing milling system in thermal power plant, and can also adapt to the power boiler milling needs of chemical industry and paper mill. It is a kind of high efficiency pulverizing equipment that completes the combination of coal grinding, drying and coal transfer. It has the characteristics of simple system, low power consumption and metal consumption, simple operation and low noise, so the fan coal mill is widely used in the direct blowing powder making system of burning lignite boiler.

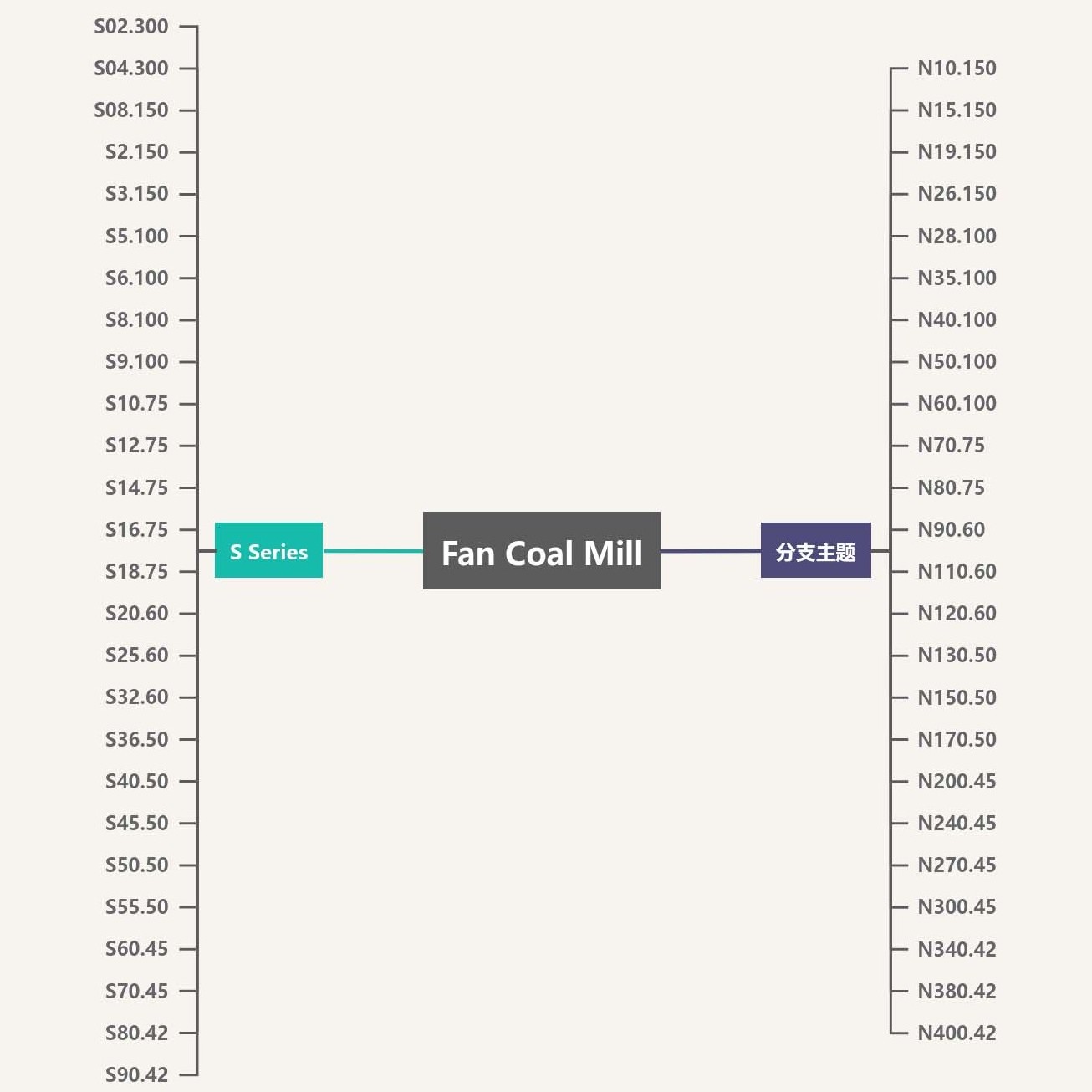

In December 1978, our company introduced KSG fan mill manufacturing technology from EVT, with 50 series of "N" "S". N series is suitable for lignite and wood lignite with grinding moisture less than 40% -70%, the maximum output of single machine is 200t / h, S series is suitable for bituminous coal and hard lignite with grinding moisture less than 40%, the maximum output of single machine is 90t / h, these specifications can widely meet the needs of users.

Working principle of fan coal mill: raw coal is sent into the flue gas pipeline, preheated with the action of thermal flue gas,

and then enters the mill. Coal and flue gas enter the mill gate, and the coal is distributed along the inner diameter of the

impact wheel, and the coal is crushed under the impact and friction of the impact wheel. At the same time, it also eliminates most of the moisture in the coal, and completes the full drying. The conveying gas and pulverized coal move in the volute area and finally enter the pulverized coal pipe or the outlet of the coal mill.

The impact wheel also plays the role of crushing coal and ventilation. The ventilation capacity of the fan coal mill system

includes: flue gas extracted from the boiler combustion chamber, air preheater hot air, steam and air leakage evaporated from raw coal, hot air blown by the bearing side wall as sealing gas to prevent the dust in the machine from the gap between the main shaft and the shell.

The fan mill has a strong impact wheel and reliable double bearings, so it can output coal containing impurities and can withstand instantaneous overload.

The impact wheel of the cantilever structure has the advantage of easy disassembly and can be replaced in a short time.

In December 1978, our company introduced KSG fan mill manufacturing technology from EVT, with 50 series of "N" "S". N series is suitable for lignite and wood lignite with grinding moisture less than 40% -70%, the maximum output of single machine is 200t / h, S series is suitable for bituminous coal and hard lignite with grinding moisture less than 40%, the maximum output of single machine is 90t / h, these specifications can widely meet the needs of users.

Working principle of fan coal mill: raw coal is sent into the flue gas pipeline, preheated with the action of thermal flue gas,

and then enters the mill. Coal and flue gas enter the mill gate, and the coal is distributed along the inner diameter of the

impact wheel, and the coal is crushed under the impact and friction of the impact wheel. At the same time, it also eliminates most of the moisture in the coal, and completes the full drying. The conveying gas and pulverized coal move in the volute area and finally enter the pulverized coal pipe or the outlet of the coal mill.

The impact wheel also plays the role of crushing coal and ventilation. The ventilation capacity of the fan coal mill system

includes: flue gas extracted from the boiler combustion chamber, air preheater hot air, steam and air leakage evaporated from raw coal, hot air blown by the bearing side wall as sealing gas to prevent the dust in the machine from the gap between the main shaft and the shell.

The fan mill has a strong impact wheel and reliable double bearings, so it can output coal containing impurities and can withstand instantaneous overload.

The impact wheel of the cantilever structure has the advantage of easy disassembly and can be replaced in a short time.

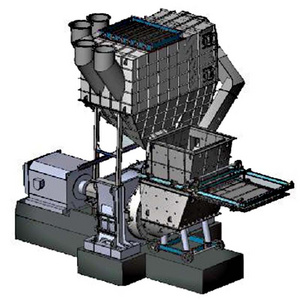

Structure diagram of the fan coal mill

Product Paramenters

Fan Coal Mill Parameters Product In Recent Years

|

TS

|

|

S 9.100

|

S 12.75

|

S 12.75

|

S 14.75

|

S 18.75

|

S 45.50

|

|

|

rated output t/h

|

|

9

|

12

|

12

|

14

|

18

|

45

|

|

|

Main motor

|

power kw

|

200

|

280

|

320

|

320

|

500

|

1000

|

|

|

|

voltage v

|

6000

|

6000

|

6000

|

6000

|

6000

|

6000

|

|

|

|

speed r/min

|

1000

|

743

|

743

|

743

|

743

|

497

|

|

|

user

|

|

Shenyang

antibiotic factory |

Xilinhot

Power Plant |

Ulanhot

Power Plant |

Genhe

power plant |

Xiaolongtan power plant

|

Shenhai power plant

|

|

Hot Searches